CNC Punching

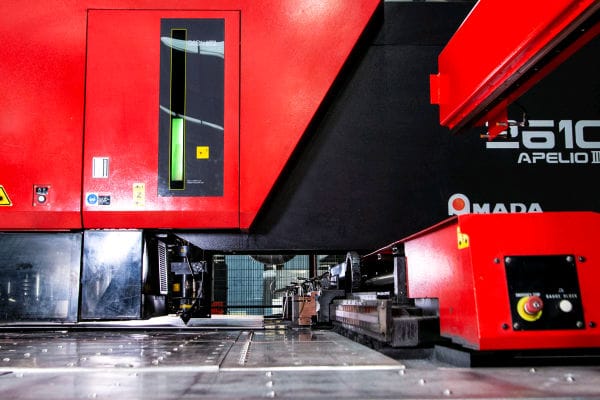

GMC is experienced in punching metal components from various materials including; mild steel, stainless steel, aluminium, zintec, copper and brass. Our investment in the latest technology and machinery alongside our wealth of expertise ensures that GMC can create complex components more efficiently and at a higher quality than the competition. This offer of efficiency, quality and value for money is assured by our highly experienced team and the proficient use of AMADA CNC punching machines.

Computer Numerically Controlled (CNC) punching plays an important role in sheet metal manufacturing and fabrication. CNC punch presses can deliver a potentially quicker and more economical component, dependant on its intricacy and purpose. Simple profiles and large volumes are ideally suited to punching.

The ability to produce components at a high speed and with a high accuracy enables GMC to offer high quality components at a competitive price.

The AMADA punch press machines are capable of producing a large variety of shapes, from simple circles or rectangles to overlapping geometrical 3D designs that can allow for increased flexibility in the fabrication of sheet metal components.

GMC integrates CAD and RADAN software with the CNC machinery, calculating the most efficient process and component nesting. This allows GMC to have maximum material utilisation, minimises material wastage and provides a quicker turn around.

CNC controlled punch and laser combination machines are capable of even more, allowing for both processes without the need for extra tool changes or increased set up costs. The AMADA punch machines can also perform simple forming and tapping operations to be carried out during the same cycle.

AMADA MP automated material handling machines feed our CNC and combination machines generating further efficiency, quality and capacity at GMC. Automated handling systems; reduce down time between jobs, minimise manual handling, allow for job scheduling, provide automatic material checks and allow for a ‘lights out’ production capability.

Two fully automated AMADA CNC punching and combination machines at GMC are able punch material up to 4.5mm thick and sheet sizes up to 3m x 1.5m.