Welcome to our comprehensive guide to sheet metal fabrication! In this article, we will delve into the world of sheet metal fabrication and provide you with all the essential information you need to know. Whether you are a professional in the industry or a novice looking to learn more, we’ve got you covered. Let’s dive right in!

What is Sheet Metal Fabrication?

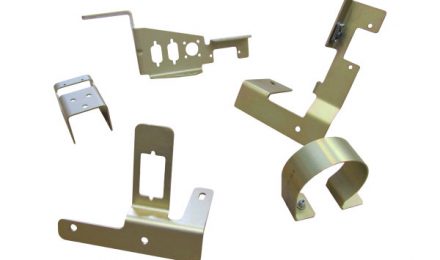

Sheet metal fabrication is a manufacturing process that involves transforming flat sheets of metal into various components and products. It is a fundamental part of many industries, including automotive, aerospace, construction, pharmaceutical, mining, and manufacturing. Through a combination of cutting, bending, and assembling techniques, sheet metal fabricators create precise components used in a wide range of applications.

The Sheet Metal Fabrication Process

- Design and Planning

The first step in sheet metal fabrication is the design and planning phase. Skilled engineers and designers work closely with clients to understand their requirements and develop detailed designs using computer-aided design (CAD) software. This phase involves considering factors such as material selection, product functionality, and manufacturing feasibility.

- Material Selection

Choosing the right material is crucial in sheet metal fabrication. The selection depends on factors such as the desired product properties, environmental conditions, and cost considerations. Commonly used materials include stainless steel, aluminium, brass, copper, and mild steel, each with its unique characteristics and applications.

- Cutting and Shearing

Once the design and material selection are finalized, the fabrication process begins with cutting and shearing the sheet metal into the desired shape and size. Various methods such as laser cutting and CNC punching are employed to achieve precise and clean cuts.

- Bending and Forming

After cutting, the next step is bending and forming the sheet metal. This process involves using specialized machinery, such as press brakes and rollers, to shape the metal into the desired form. Skilled operators ensure accuracy and consistency in the bending process, creating complex geometries with tight tolerances.

- Joining and Assembly

Joining and assembly techniques are employed to connect different components and create the final product. Common methods include welding, riveting, soldering, and adhesive bonding. Skilled welders and technicians ensure strong and reliable joints, guaranteeing the structural integrity of the fabricated parts.

- Surface Finishing

Surface finishing is the final step in the sheet metal fabrication process. It involves various treatments to enhance the appearance, durability, and corrosion resistance of the fabricated components. Some common finishing techniques include painting, powder coating, anodizing, and plating.

Applications of Sheet Metal Fabrication

Sheet metal fabrication finds applications in a wide range of industries and products. Here are some common examples:

- Automotive Industry

Sheet metal fabrication plays a vital role in the automotive industry, where it is used to manufacture car bodies, chassis, and various interior and exterior components. The precision and durability of fabricated sheet metal parts ensure the safety and performance of vehicles.

- Aerospace Industry

In the aerospace industry, sheet metal fabrication is utilized to create aircraft structures, aircraft seating, wings, fuselages, and engine components. The lightweight yet robust nature of sheet metal makes it an ideal choice for aircraft manufacturing, enabling fuel efficiency and aerodynamic designs.

- Construction Sector

Sheet metal fabrication is extensively used in the construction sector for architectural features, HVAC (heating, ventilation, and air conditioning) systems, and structural elements. Its versatility allows for the creation of custom designs that meet specific project requirements.

- Pharmaceutical & Medical

The pharmaceutical and medical industries use a large range of sheet metal in components. Products include; automated storage systems, laboratory equipment, scanning and x-ray machines etc.