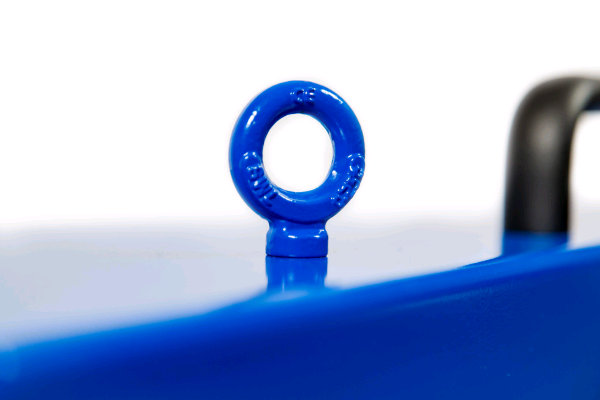

Powder Coating Services

Our Capabilities

Metals We Can Powder Coat

- Mild Steel

- Stainless Steel

- Aluminium

- Brass

- Copper

Metal Thickness

- Mild Steel: 0.5mm-25mm

- Stainless Steel: 0.5mm-20mm

- Aluminium: 0.5mm-16mm

- Brass: 0.5mm-10mm

- Copper: 0.5mm-8mm

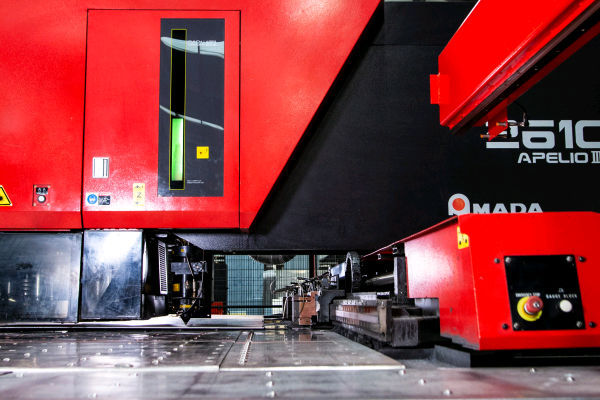

Sheet Sizes

- Up to 3000 x 1500mm

Our Equipment