Sheet Metal Design and Prototyping

Our Metal Design and Prototyping Services

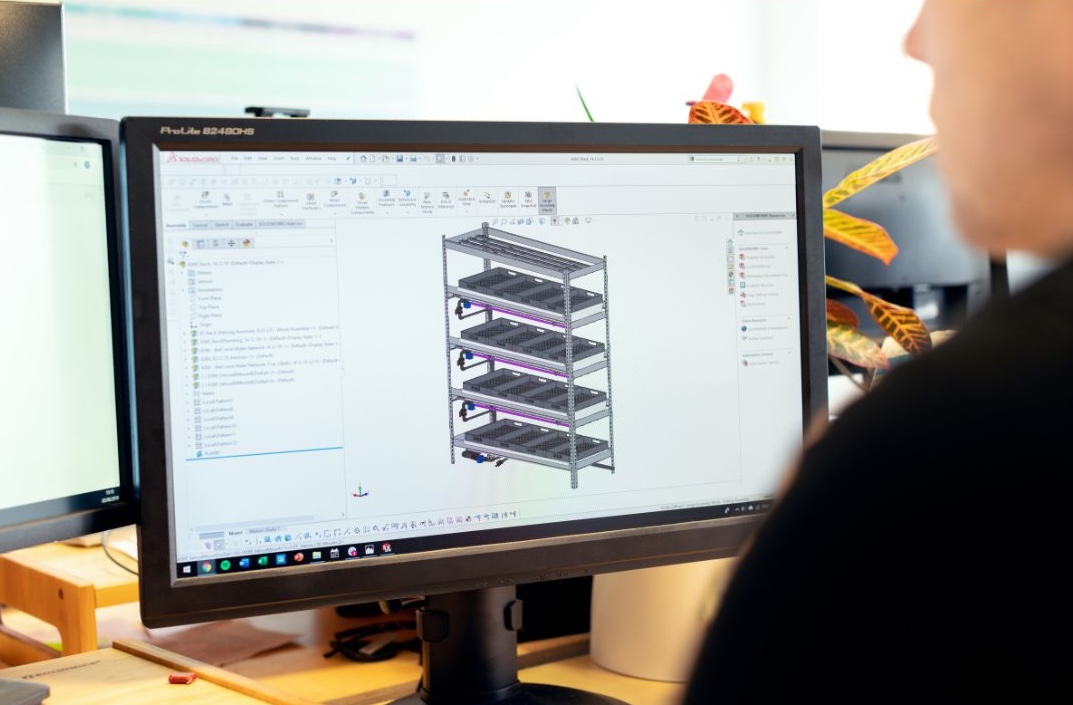

With over 60 years in the industry, Greengate Metal Components offers customers an outstanding level of service when it comes to sheet metal design (CAD) and sheet metal prototyping. With experienced technical sales managers and the latest sheet metal design & CAD/CAM technology, customers can be assured that Greengate Metal Components can be relied upon from conception to completion of their sheet metal fabrication project.

Contact UsWhat Is Sheet Metal Prototyping?

At Greengate Metal Components, sheet metal prototyping is a key stage in turning concepts into reality. Using advanced CAD (Computer-Aided Design) software, we develop precise digital models which guide the fabrication of accurate, high-quality prototypes. These early-stage components are produced using techniques like CNC laser cutting, bending, and welding, allowing us to test form, fit, and function before full production.

Prototyping helps identify potential design improvements, reduces risk, and ensures cost-effective manufacturing. By combining expert craftsmanship with cutting-edge CAD and fabrication technology, Greengate delivers reliable, tailored prototypes that support innovation and accelerate product development for our clients.

Contact UsBenefits of Prototyping Before Sheet Metal Fabrication Projects

Design Validation

Early Problem Detection

Faster Development Cycles

Cost Efficient

Bespoke CAD Services For Sheet Metal Fabrication Projects

At Greengate Metal Components, we provide bespoke CAD services tailored to sheet metal fabrication projects of all types. Our skilled design team uses advanced CAD software to produce accurate, custom drawings based on your specific requirements. These detailed models enhance precision, improve manufacturability and support a smooth transition into production.

By working closely with our clients, we transform initial concepts into fabrication-ready designs, helping to minimise errors and reduce lead times. Whether it is a one-off prototype or a full production run, our CAD expertise ensures your project is optimised for quality, efficiency and cost-effectiveness, delivering reliable results every time.

Contact UsWhy Choose Greengate Metal Components?

Greengate Metal Components operates with the latest CAD/CAM & design software to provide product simulations on new concepts, creating workable manufacturing programs, and turning customer concepts into a completed component. By running these programs alongside our production control system, prototyping and experience we are able to offer accurate lead times and costs at the very early stages of our customers’ metal fabrication projects.

Our engineers and dedicated technical sales managers work closely with clients to provide the highest quality product at a competitive rate. By making manufacturing improvements, efficiency improvements and process streamlining. Our goal is to work in partnership with customers to create a high-quality, value-engineered sheet metal product that is delivered on time and with an exceptional level of service.

Contact Us

Contact Us

Looking for sheet metal design and prototyping services? Contact our helpful team at Greengate Metal Components to get a bespoke quote.

Contact UsSectors We Can Provide Sheet Metal Prototyping Services For

Greengate Metal Components offers dependable, high-quality sheet metal design and prototyping services, tailored to meet the varied requirements of a wide range of businesses, including:

Contact UsCAD For Sheet Metal Fabrication

CAD (Computer-Aided Design) plays a vital role in modern sheet metal fabrication. It allows engineers and designers to create highly accurate, detailed digital models of components before any physical work begins. These models guide every stage of the fabrication process, from cutting and bending to assembly, ensuring precision and consistency.

CAD improves efficiency by highlighting potential issues early, reducing waste and minimising costly errors. It also enables easy modifications, supports custom designs, and speeds up production timelines.

Prototyping For Sheet Metal Fabrication Projects

Sheet metal fabrication prototyping is the process of creating an initial, functional version of a metal component before full-scale production begins. It allows designers and engineers to test form, fit and function, helping to identify and resolve design issues early. Prototypes are produced using processes such as laser cutting, bending and welding, often guided by precise CAD models.

Sector Design & Prototyping

Aerospace

At Greengate Metal Components, we specialise in sheet metal prototyping and design tailored for the aerospace sector. Precision and durability are critical, as components must withstand extreme conditions while maintaining lightweight efficiency.

Our expert team collaborates closely with engineers to develop prototypes that meet strict industry standards, ensuring optimal performance and safety. Using advanced fabrication techniques, we deliver bespoke solutions rapidly, helping aerospace manufacturers reduce lead times and bring innovative designs to life.

Aerospace Fabrication

Architectural Metal Work

At Greengate Metal Components, we specialise in architectural metalwork, delivering bespoke sheet metal prototypes designed for the construction and design industries. Our work focuses on creating durable, aesthetically pleasing components that meet exacting standards for both form and function.

From intricate façades to structural elements, we collaborate closely with architects and contractors to bring innovative designs to reality. Using advanced fabrication techniques, we ensure each piece combines strength with visual appeal, helping projects achieve lasting impact and seamless integration.

Architectural Metal Work Fabrication

Pharmaceutical & Medical

At Greengate Metal Components, we specialise in sheet metal prototyping and design for the pharmaceutical and medical sectors. Our precision-engineered components meet rigorous hygiene and safety standards, essential for medical devices and laboratory equipment.

We work closely with manufacturers to produce corrosion-resistant, easy-to-clean parts that withstand sterilisation processes. Our expertise ensures compliance with industry regulations, delivering reliable, high-quality prototypes that support innovation in healthcare.

Pharmaceutical and Medical Fabrication

Kiosk & Vending Machines

At Greengate Metal Components, we specialise in sheet metal prototyping and design for kiosk and vending machine manufacturers. Our precision-crafted components are built to withstand constant use and harsh environments, ensuring durability and reliability.

We focus on creating secure, tamper-resistant enclosures with smooth finishes that enhance user experience. Working closely with designers, we develop customised solutions that allow for easy assembly and maintenance while meeting strict industry standards.

Kiosk and Vending Machine Fabrication

Metal Cabinets & Enclosures

At Greengate Metal Components, we focus on producing precision sheet metal prototypes for metal cabinets and enclosures used across various industries. Our designs prioritise strength and protection, safeguarding electrical and electronic equipment from external damage and environmental hazards. We work closely with clients to customise dimensions, ventilation, and access points, ensuring practical usability without compromising security.

Metal Cabinet and Enclosure Fabrication

Mining & Material Extraction

In the mining and material extraction industry, robust sheet metal components are essential to withstand harsh conditions and heavy wear. At Greengate Metal Components, we design and prototype parts that deliver exceptional durability against abrasion, impact, and corrosion. Our expertise includes creating customised enclosures, protective guards, and structural elements that support heavy machinery and ensure operational safety.

Mining and Material Extraction Fabrication

EV Chargers

Building EV chargers means creating tough, reliable housings that protect all the sensitive electronics inside. At Greengate Metal Components, we work closely with manufacturers to design and prototype sheet metal parts that can handle all kinds of weather and wear. We focus on making sure chargers stay safe, cool, and easy to install, while also looking clean and modern. Our goal is to help bring EV chargers to market that last longer and perform better, fitting smoothly into everyday surroundings.

EV Charger Fabrication

Defence Industry

In the defence industry, reliability and precision are non-negotiable. At Greengate Metal Components, we specialise in producing rugged sheet metal prototypes designed to meet the toughest military specifications.

Our components are engineered to withstand extreme conditions, from harsh environments to intense mechanical stress. We work closely with defence contractors to deliver secure, lightweight solutions for equipment housings, vehicle parts, and protective enclosures.

Defence FabricationOur Services

CNC Metal Laser Cutting

At Greengate Metal Components, our CNC metal laser cutting services offer exceptional precision, speed, and efficiency for a wide variety of fabrication needs. Using advanced laser technology, we can cut complex shapes and fine details with minimal waste and high repeatability.

Our skilled team ensures consistent quality and fast turnaround times, whether for prototypes or large-scale production. We work with various metals and thicknesses, delivering reliable results that meet the exact specifications of each project.

CNC Metal Punching

At Greengate Metal Components, our CNC metal punching services offer fast, accurate, and cost-effective solutions for producing complex metal parts.

Using advanced CNC punching machines, we can handle a wide range of materials and thicknesses with exceptional precision. This technology enables high-speed production with minimal waste, making it ideal for both small and large batch runs.

Sheet Metal Assembly

Our sheet metal assembly services are designed to deliver fully integrated, ready-to-use components that meet exact specifications.

We combine expert fabrication with skilled assembly techniques, including welding, fastening, and finishing, to ensure each product is precise and reliable. Our team works closely with clients to streamline production, reduce lead times, and maintain the highest quality standards.

Metal Welding

We offer professional metal welding services as part of our fabrication capabilities. Our skilled welders use advanced techniques and equipment to ensure strong, precise, and clean welds across a variety of metals.

Whether for structural frameworks or detailed component assembly, we maintain high standards of quality and consistency. With a focus on durability and accuracy, our welding services support both small and large-scale projects, tailored to meet the specific requirements of each client.

Metal Bending & Forming

At Greengate Metal Components, our metal bending and forming services combine precision, efficiency, and versatility to meet a wide range of project requirements. Using advanced CNC press brakes and skilled technicians, we can accurately shape sheet metal into complex forms with tight tolerances.

Our expertise in metal forming allows us to support custom designs, helping clients achieve optimal functionality and performance.

Metal Design & Prototyping

At Greengate Metal Components, our metal design and prototyping services ensure your ideas are brought to life with precision and efficiency. Using advanced CAD software and engineering expertise, we work closely with clients to develop accurate prototypes that meet functional and aesthetic requirements.

This process allows for thorough testing, refinement, and validation before full-scale production, reducing risk and saving time.

Metal Powder Coating

We offer professional metal powder coating services designed to enhance durability, appearance, and corrosion resistance.

Our advanced powder coating process delivers a smooth, uniform finish that adheres exceptionally well to metal surfaces, ensuring long-lasting performance. Available in a wide range of colours and textures, our coatings are ideal for both functional and aesthetic applications.