Sheet Metal Bending and Forming Services

Our Metal Bending and Forming Services

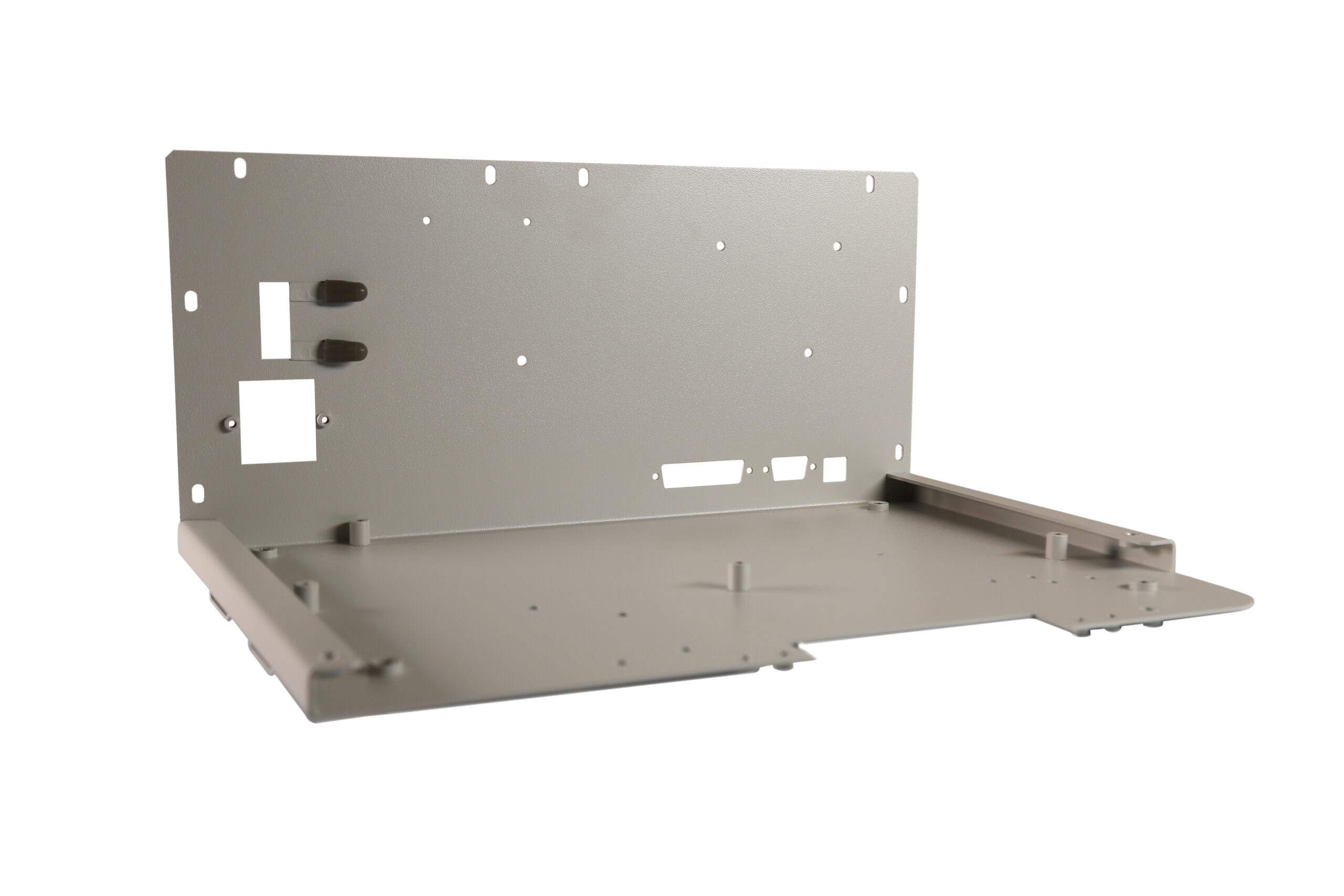

Greengate Metal Components offers the versatility to bend and form a wide range of metals, sheet sizes and material thickness, whether it be in mild steel, stainless steel, aluminium and more. Our modern sheet metal fabrication and manufacturing facility can accommodate both large and small batch sheet metal bending runs, giving more flexibility to our customers’ requirements.

What Is Sheet Metal Bending and Forming?

Sheet metal bending and forming is the process of shaping flat metal sheets into desired angles or complex geometries without cutting or removing material. At Greengate Metal Components, we use advanced press brakes and tooling to deliver precise, repeatable bends across a range of metals, including steel, aluminium and stainless steel.

Forming techniques such as rolling, folding and stamping allow us to create curves, channels and intricate profiles to suit your specifications. These processes are essential in producing enclosures, brackets, panels and structural components with accuracy and consistency, supporting industries from automotive to construction with high-quality, custom-fabricated metal parts.

Contact UsBenefits of Choosing Sheet Metal Bending and Forming Services

Precision and Accuracy

Cost Effective

Versatility

Speed and Efficiency

Bespoke Sheet Metal Bending Services

At Greengate Metal Components, our bespoke sheet metal bending services are tailored to meet your exact design and functional requirements. Using advanced CNC press brakes and precision tooling, we deliver accurate, repeatable bends across a wide range of materials, including steel, aluminium and stainless steel. Whether you need simple angles or complex folded components, we work to your specifications to ensure a perfect fit and finish.

Our expert team handles everything from prototypes to full production runs, supporting industries such as automotive, construction and industrial equipment. With a focus on quality, consistency and fast turnaround, our bespoke bending services help reduce assembly time, improve part strength and streamline your manufacturing process.

Contact UsWhy Choose Greengate Metal Components?

Greengate Metal Components has a total of 6 AMADA Press brakes with the capability of pressing 25 tonnes up to 170 tonnes and the ability to bend sheet metal lengths up to 4 meters. This equipment allows for outstanding reliability, accuracy and efficiency when it comes to bending and forming sheet metal. Resulting in a high-quality product for our customers.

Continuous investment in the latest software and technology, alongside our engineers’ expertise, allows Greengate Metal Components to exceed the requirements of even the most challenging contracts from our customers whilst remaining competitive.

Contact Us

Our Expert Sheet Metal Bending Machinery

AMADA HFE3i

The Amada HFE3i is a high-performance CNC press brake, ideal for precision sheet metal bending and forming. At Greengate Metal Components, we use the HFE3i to achieve accurate, repeatable bends across a variety of materials and thicknesses. Its intelligent interface, automatic setup features and multi-axis control allow for complex part geometry and quick changeovers, improving efficiency and reducing downtime.

With powerful hydraulic performance and real-time angle correction, it ensures exceptional bending quality and consistency. The Amada HFE3i supports both small batches and large production runs, making it an essential part of our commitment to delivering reliable, high-precision metal components.

Contact Us

Interested in our sheet metal bending and forming services? Contact Greengate Metal Components to speak to a member of our team for a bespoke quote.

Contact UsMetal Bending and Forming Capabilities

Materials We Work With

- Stainless Steel

- Mild Steel

- Aluminium

- Zintec/Galvanised Steel

- Copper

- Brass

- Coated Sheets

Metal Thickness

- Mild Steel: Up to 10mm

- Stainless Steel: Up to 10mm

- Aluminium: Up to 10mm

- Brass: Up to 10mm

- Copper: Up to 10mm

Part Sizes

Up to 4000mm

Sectors We Can Provide Sheet Metal Bending Services For

Greengate Metal Components offers dependable, high-quality CNC laser cutting services, tailored to meet the varied requirements of a wide range of businesses, including:

Contact UsOur Latest Blogs

Sheet Metal Bending Services For Aerospace

At Greengate Metal Components, we specialise in sheet metal bending services tailored for the aerospace industry. Our precision engineering ensures components meet the highest standards for strength and durability.

Utilising advanced machinery and skilled technicians, we deliver consistent, accurate bends on a wide range of metals. We understand the critical nature of aerospace parts, so quality control is paramount throughout production.

Aerospace Metal Fabrication

Sheet Metal Bending Services For Architectural Metal Work

At Greengate Metal Components, we provide expert architectural metal work services designed to enhance both form and function. Our skilled team works with a variety of metals to create bespoke solutions that meet the unique demands of architectural projects.

Precision and attention to detail are at the core of our process, ensuring each piece complements the design vision while offering lasting durability. From concept to completion, we collaborate closely with clients to deliver high-quality metalwork that elevates any building or structure.

Aerospace Metal Fabrication

Sheet Metal Bending Services For The Pharmaceutical and Medical Sector

Greengate Metal Components offers specialised sheet metal bending services for the pharmaceutical and medical sectors. We focus on precision and cleanliness to meet strict industry standards. Our processes ensure components are manufactured with exact tolerances and smooth finishes, essential for medical equipment and pharmaceutical machinery. Compliance with hygiene and safety regulations is a top priority.

With advanced technology and experienced staff, we deliver reliable, high-quality metal parts that support critical healthcare applications and maintain the integrity of medical environments.

Pharmaceutical and Medical Fabrication

Sheet Metal Bending Services For Kiosk and Vending Machines

At Greengate Metal Components, we specialise in sheet metal bending services for kiosk and vending machine manufacturers. Our expertise allows us to produce robust, precise metal parts that withstand daily use and harsh environments. We work with a variety of metals to create components that fit perfectly within compact designs, ensuring both durability and aesthetic appeal.

Understanding the importance of reliable performance, we focus on delivering consistent quality and tight tolerances to support the functionality and longevity of vending and kiosk equipment.

Kiosk and Vending Machine Fabrication

Sheet Metal Bending Services For Metal Cabinets and Enclosures

Greengate Metal Components provides expert sheet metal bending services tailored for metal cabinets and enclosures. Our team produces strong, precise components designed to protect sensitive equipment and ensure secure storage. We work with various metals to create durable, high-quality panels and frames that meet industry standards.

Attention to detail and accuracy are key in our process, allowing us to deliver bespoke solutions that fit perfectly within your design specifications. Reliability and finish quality are central to every cabinet and enclosure we manufacture.

Metal Cabinets and Enclosure Fabrication

Sheet Metal Bending Services For Mining and Material Extraction

At Greengate Metal Components, we specialise in sheet metal bending services for the mining and material extraction industries. Our durable metal components are engineered to withstand harsh environments and heavy wear. We work with tough metals to produce strong, reliable parts that meet the demanding standards of mining equipment. Precision and consistency are essential to ensure safety and performance.

Our expert team delivers customised solutions designed to support the rugged conditions faced in extraction operations, helping to maximise efficiency and equipment lifespan.

Mining and Material Extraction Fabrication

Sheet Metal Bending Services For EV Chargers

Greengate Metal Components offers specialised sheet metal bending services for the electric vehicle (EV) charger industry. We produce precision metal parts that combine durability with sleek design, essential for modern charging stations. Our team works with high-quality materials to ensure components withstand outdoor conditions and continuous use.

Accuracy in bending ensures perfect fits for complex assemblies, supporting the functionality and safety of EV chargers. We partner with manufacturers to deliver reliable, custom metalwork that meets the evolving demands of sustainable transportation infrastructure.

EV Charger Fabrication

Sheet Metal Bending Services For The Defence Industry

At Greengate Metal Components, we specialise in sheet metal bending for the defence industry, producing components that meet the exacting demands of military equipment. We work with high-grade metals to create strong, durable parts designed to withstand harsh environments and heavy use.

Our precision bending ensures components fit perfectly in complex assemblies like vehicle armour, weapon housings, and communication systems. We understand the critical need for reliability and compliance with defence standards, delivering metalwork that supports mission-critical operations with confidence.

Defence Fabrication

Our Services

CNC Metal Laser Cutting

At Greengate Metal Components, our CNC metal laser cutting services offer exceptional precision, speed, and efficiency for a wide variety of fabrication needs. Using advanced laser technology, we can cut complex shapes and fine details with minimal waste and high repeatability.

Our skilled team ensures consistent quality and fast turnaround times, whether for prototypes or large-scale production. We work with various metals and thicknesses, delivering reliable results that meet the exact specifications of each project.

CNC Metal Punching

At Greengate Metal Components, our CNC metal punching services offer fast, accurate, and cost-effective solutions for producing complex metal parts.

Using advanced CNC punching machines, we can handle a wide range of materials and thicknesses with exceptional precision. This technology enables high-speed production with minimal waste, making it ideal for both small and large batch runs.

Sheet Metal Assembly

Our sheet metal assembly services are designed to deliver fully integrated, ready-to-use components that meet exact specifications.

We combine expert fabrication with skilled assembly techniques, including welding, fastening, and finishing, to ensure each product is precise and reliable. Our team works closely with clients to streamline production, reduce lead times, and maintain the highest quality standards.

Metal Welding

We offer professional metal welding services as part of our fabrication capabilities. Our skilled welders use advanced techniques and equipment to ensure strong, precise, and clean welds across a variety of metals.

Whether for structural frameworks or detailed component assembly, we maintain high standards of quality and consistency. With a focus on durability and accuracy, our welding services support both small and large-scale projects, tailored to meet the specific requirements of each client.

Metal Bending & Forming

At Greengate Metal Components, our metal bending and forming services combine precision, efficiency, and versatility to meet a wide range of project requirements. Using advanced CNC press brakes and skilled technicians, we can accurately shape sheet metal into complex forms with tight tolerances.

Our expertise in metal forming allows us to support custom designs, helping clients achieve optimal functionality and performance.

Metal Design & Prototyping

At Greengate Metal Components, our metal design and prototyping services ensure your ideas are brought to life with precision and efficiency. Using advanced CAD software and engineering expertise, we work closely with clients to develop accurate prototypes that meet functional and aesthetic requirements.

This process allows for thorough testing, refinement, and validation before full-scale production, reducing risk and saving time.

Metal Powder Coating

We offer professional metal powder coating services designed to enhance durability, appearance, and corrosion resistance.

Our advanced powder coating process delivers a smooth, uniform finish that adheres exceptionally well to metal surfaces, ensuring long-lasting performance. Available in a wide range of colours and textures, our coatings are ideal for both functional and aesthetic applications.