Sheet Metal Fabricators

Our Capabilities

Fabrication Services We Offer

- Laser Cutting

- Powder Coating

- Finishing

- Welding and Spot Welding

- Bending and Forming

- Product Assembly

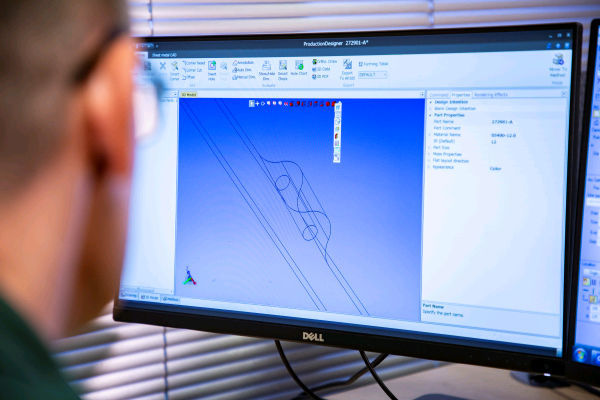

- Design and Prototyping

- CNC Metal Punching

Metal Thickness

- Mild Steel: 0.5mm-25mm

- Stainless Steel: 0.5mm-20mm

- Aluminium: 0.5mm-16mm

- Brass: 0.5mm-10mm

- Copper: 0.5mm-8mm

Sheet Sizes

- Up to 3000 x 1500mm

Our Machinery

Ventis-AJ Fibre Laser

The VENTIS-AJ is the biggest innovation in sheet metal cutting and introduces the next generation of fibre laser processing machines.

What makes this technology truly revolutionary is the innovative beam shaping system that allows for precise control of the laser beam motion. Utilizing AMADA’s high power, single diode module fibre laser engines, the VENTIS is available as 4 kW or 6 kW. These engines provide a very high quality laser beam, allowing the 4 kW VENTIS-AJ to perform similar to 6-8 kW machines, and the 6 kW VENTIS-AJ to perform similar to 8-10kW machines, with much less power requirements and an unrivalled cutting quality.

What makes this technology truly revolutionary is the innovative beam shaping system that allows for precise control of the laser beam motion. Utilizing AMADA’s high power, single diode module fibre laser engines, the VENTIS is available as 4 kW or 6 kW. These engines provide a very high quality laser beam, allowing the 4 kW VENTIS-AJ to perform similar to 6-8 kW machines, and the 6 kW VENTIS-AJ to perform similar to 8-10kW machines, with much less power requirements and an unrivalled cutting quality.

AMADA HFE3i

The AMADA HFE3i series are the latest evolution in hydraulic drive press brakes. Designed with the solid characteristics of the HFE series, the 3i series features new additions to improve productivity, as well as, a highly innovative multi-touch screen interface. The processing precision enables the production of very high quality batches, at low energy costs and with an unrivalled process stability. The extensive range of sizes (from 50 tons, 1.2 m to 400 tons, 6 m) and options mean that customers can configure the ideal bending solution for their specific needs.

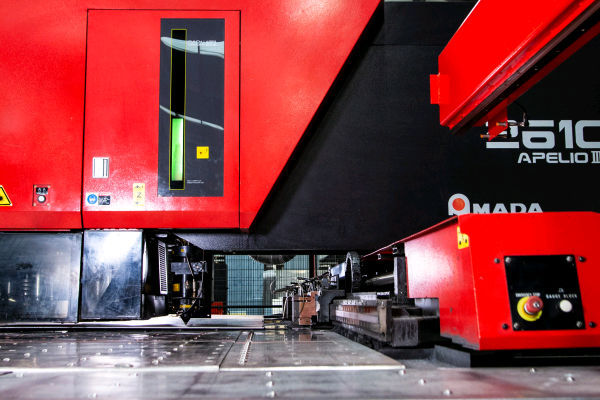

AMADA EMX-3610

The EM-MII range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing.

The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.