What is Laser Cutting?

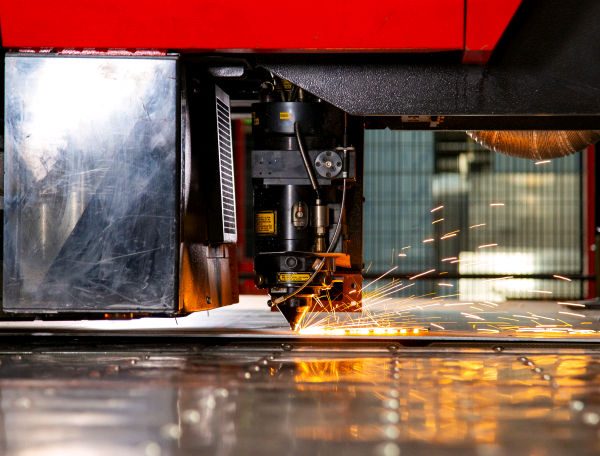

Laser metal cutting is a sophisticated, non-contact fabrication process that employs a highly focused laser beam to cut materials with unmatched precision. At its core, the technique harnesses the immense energy of a laser to melt, burn or evaporate material.

The cuts created by lasers are remarkably clean and can be intricately detailed. Lasers can be used to simply etch designs onto the surface of various materials, but given enough energy, the beam can cut through up to 25mm of mild steel, or 10mm of brass. If you’re in metal fabrication, you can surely imagine the benefits of this ability.

Although the basic theory of lasers cutting through thick metal is impressive, it would be of limited use without another important technology: computer numerical control (CNC) systems. This is the means by which designs created on a computer are translated into actual movement of the laser head, with breathtaking speed and precision.

What are laser cutters used for?

CNC fibre lasers are used for cutting the profile shape of a component out of the sheet material. The metal laser cutter can do anything that punching, guillotining, drilling or sawing could do, with high levels of speed and precision. When it comes to productivity and quality on intricate designs, CNC fibre lasers excel against other types of machinery and processes.

The non-contact nature of laser cutting means that the material’s integrity remains uncompromised. There’s no mechanical stress imposed on the sheet at all. The extremely fine laser beam gives very high precision and very low roughness and burr on the edge of the cut. This means there is reduced post processing required, particularly on thinner gauge sheet material.

The Fibre lasers we use in our laser cutting services can handle mild steel, stainless steel, aluminium, Zintec, galvanised steel, copper, brass, coated sheets and more. We cover the vast majority of the needs of the fabrication industry. Sectors ranging from aerospace to pharmaceutical, medical, automotive, retail, switchgear, have harnessed this technology to revolutionise their components & products.

How does metal laser cutting work?

At its core, the laser cutting process involves generating a high-power laser beam, which can be moved in two dimensions and switched on and off to start and stop cutting.

Technically, the beam is created through the excitation of lasing materials, which can be gases or solid-state substances (for example CO₂ or doped glass fibres). Once generated, the light produced is precisely focused and directed onto the target material using a series of high-precision mirrors or fibre-optic cables.

Once this laser beam hits the material, rapid heating occurs. That causes the material to melt, evaporate or be expelled by an assist gas, leaving behind an impeccably clean cut.

With such heat involved, the laser’s interaction with the material must be carefully managed. Excessive heat dissipation could cause expansion and distortion, which would seriously affect the precision of the cut, and possibly even damage the material beyond repair. That’s why advanced cooling mechanisms are an integral part of the process.

Safety considerations

Due to their high energy and focus, laser beams pose significant risks if not managed properly. It’s not hard to imagine what something that can cut through 25mm of steel could do to the human body. In practice, these machines are naturally tight and enclosed, and it would be highly unlikely for a hand to accidentally stray into it.

As a basic measure, operators should be equipped with appropriate protective gear including IR-proof goggles. Health hazards do extend beyond just the beam itself, however. Cutting metals can produce dust and fumes, some of which may be toxic. An efficient extraction and ventilation system is crucial to remove them. Again, the machines themselves are equipped to deal with this, not least because of the cooling that’s required.

Overall, proper maintenance and regular inspection of laser equipment are important. Ensuring that all components, particularly optics and cooling systems, are in optimal condition can prevent malfunctions. An unmodified, well-maintained laser cutting rig is arguably much safer than traditional cutting equipment. Accidents and injuries are rare.

Types of lasers used in metal cutting

Predominantly, three types of lasers are used: fibre lasers, CO₂ lasers, and crystal lasers. Each comes with its distinct benefits and applications.

- Fibre lasers represent a growing segment in laser cutting technology. They use a solid gain medium to amplify light in a glass fibre, which results in a smaller spot size compared to CO₂ lasers. This makes them exceptionally suited for cutting reflective materials such as aluminium and copper.

- CO₂ lasers have been the workhorse of industrial laser cutting for decades. They operate by using a gas mixture of carbon dioxide, nitrogen and hydrogen. Although CO₂ lasers have robust construction and effectiveness, they can be less efficient than newer designs. Still, they remain effective for cutting metals.

- Crystal lasers, including Nd and Nd:YAG (neodymium: yttrium aluminium garnet) lasers, use doped crystals to generate the laser beam. These solid-state lasers produce high-energy beams that can cut through thick, robust materials with ease. However, due to their higher production costs and limited lifespan, they’re generally restricted to niche applications, where exceptional precision or power are needed.

Conclusion

Modern metal laser cutting comes with breathtaking benefits in terms of speed, precision and cost-effectiveness, and the technology is constantly improving. A design can be made using CAD software and cut out of sheet metal in minutes, a process that would have taken hours or days of tooling in the past.

Laser cutting for metal does have its sweet spots in terms of optimal cut widths for various metals. Outside these limitations, other means of fabrication need to be considered. However, within those ranges, there’s no better way to achieve the levels of precision demanded by the pharmaceutical and aerospace sectors, or the speed and cost-effectiveness required by mass-produced goods manufacturers.

If you are interested in our metal laser cutting services, please get in touch with us to find out more.