Mining, Material Extraction & Material Production

What Is Mining, Material Extraction & Material Production?

Greengate Metal Components manufactures a wide range of products for global leaders in Minerals, Oil & Gas, Chemical and Power & Energy industries. By working closely with partners in the primary sector GMC has the wealth of experience and resources required to deliver high quality sheet metal fabrication services and reliable products at a competitive rate.

A sample of some of the components we manufacture for this industry include; components for, production equipment, pumping equipment, materials handling & separation equipment, screening equipment & washing equipment. Greengate Metal Components understands that in this industry productivity is key. Our engineers and technical sales managers work in partnership with our customers streaming processes, making efficiency improvements and design & manufacturing improvements.

Our goal is to create a high quality, value engineered product that is delivered on time and with an exceptional level of service.

Greengate Metal Components operates under the most stringent quality management and production control system requirements. Offering customers full product and material traceability throughout our supply chain and production process.

Contact UsOther sectors that you may be interested in

Pharmaceutical and Medical

Find out more

Architectural Steel Work

Find out more

Aerospace

Find out moreOur Services

Sheet Metal Fabrication

Stainless Steel Fabrication

Aluminium Fabrication

Copper Fabrication

Mild Steel Fabrication

CNC Metal Laser Cutting

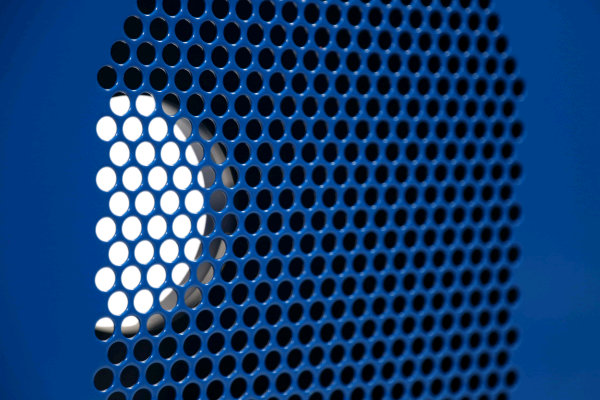

CNC Metal Punching

Sheet Metal Assembly

- Sheet Metal Design and Prototyping Services

- CNC Sheet Metal Punching Services

- Metal Sheet Laser Cutting Services

- Sheet Metal Bending Services

- Sheet Metal Spot Welding Services

- Metal Powder Coating Services

- Sheet Metal Product Assembly Services

- Sheet Metal Fabrication Services

Our Machinery

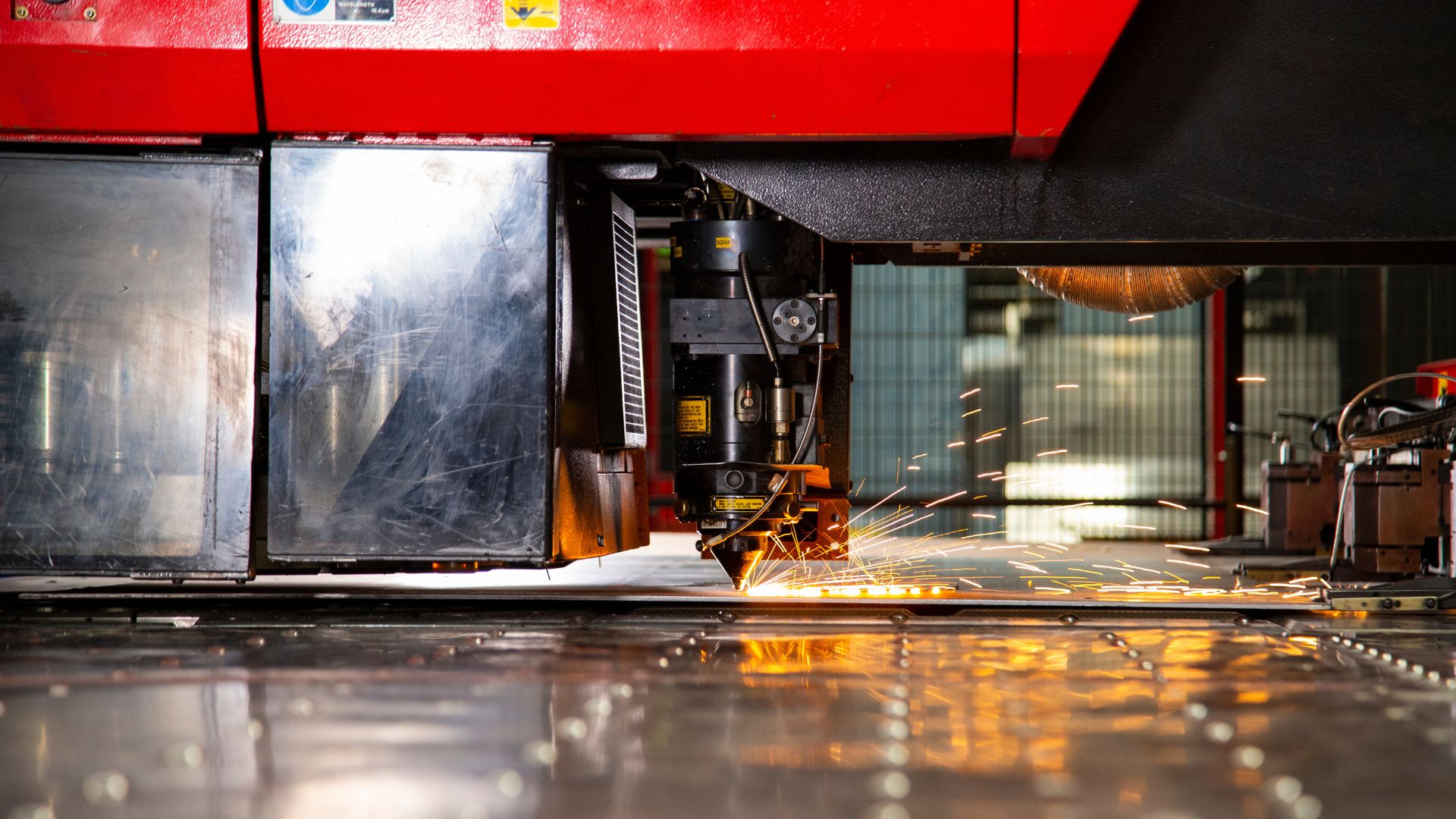

CNC Laser Cutting Machine

The VENTIS-AJ is a high-performance sheet metal cutting machine using advanced fibre laser technology and a beam-shaping system for accurate control. Available in 4 kW and 6 kW versions, it delivers cutting quality comparable with much higher power machines while keeping energy use low.

AMADA HFE3i

The AMADA HFE3i series is a modern hydraulic press brake that builds on the proven HFE range and adds a multi-touch screen interface. It offers precise bending, stable processing and low energy consumption across a wide choice of sizes and configurations.

AMADA EMX-3610

The EM-MII punching range uses a 30 ton dual servo electric motor system together with AMADA’s advanced tool turret. Optional tool identification and dedicated tapping units help cut setup times and support efficient, high-quality processing.