Aerospace Metal Fabrication

What Is Aerospace Metal Fabrication?

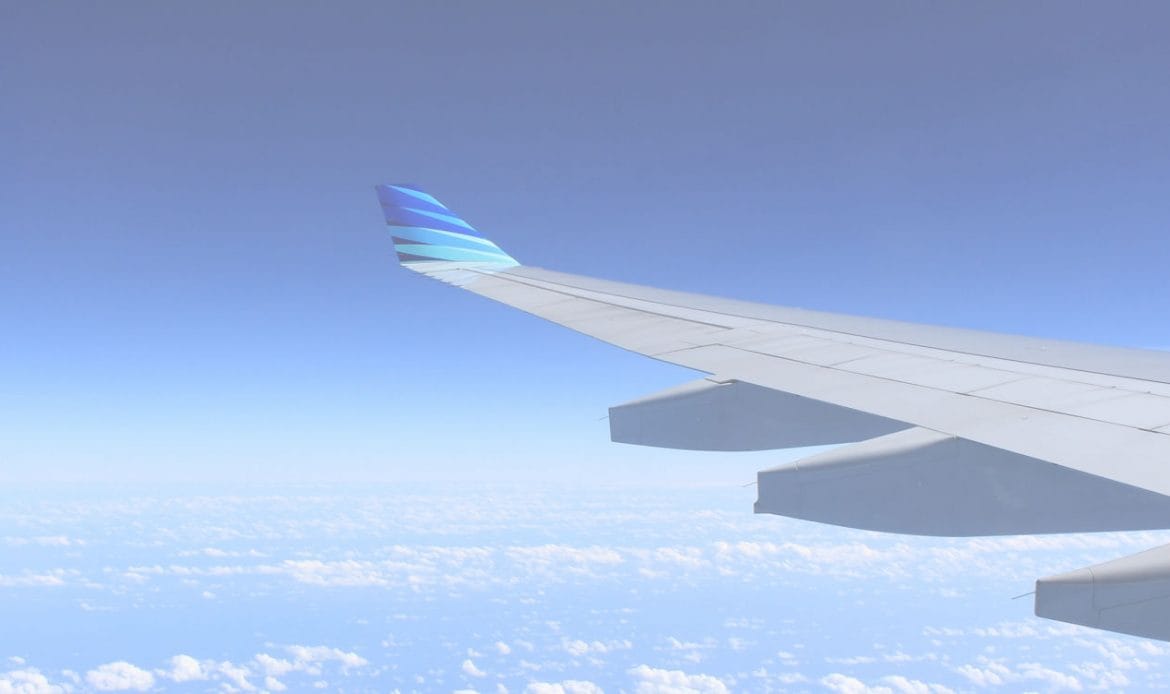

As the demand for commercial air travel continues to grow, the need for reliable, efficient aerospace metal fabrication has never been greater. To support the production of modern, fuel-efficient aircraft, manufacturers are investing heavily in advanced fabrication techniques and innovative materials that improve performance, safety, and sustainability.

Contact UsAerospace Products & Components

Outsource Aerospace Sheet Metal Fabrication

Outsourcing the metal fabrication of aerospace components to Greengate Metal is a smart choice for businesses looking to deliver high-quality parts without managing production in-house.

Partnering with a trusted provider like Greengate Metal Components in the aerospace sector allows companies to meet demand quickly and consistently while focusing on innovation.

Our Services

At Greengate Metal Components, we offer a complete range of aerospace sheet metal fabrication services, including:

Sheet Metal Fabrication

Stainless Steel Fabrication

Aluminium Fabrication

Copper Fabrication

Mild Steel Fabrication

CNC Metal Laser Cutting

CNC Metal Punching

Sheet Metal Assembly

- Design & Prototyping: Precise CAD/CAM designs

- Laser Cutting: Accurate, clean finishes

- CNC Punching: Intricate patterns

- Bending & Forming: Shaping components

- Welding: Durable assemblies

- Surface Finishing: Protective coatings

- Product Assembly: Ready-to-use components

Benefits of Aerospace Sheet Metal Fabrication

Precision and expertise

Bespoke solutions

Cost savings

Faster time-to-market

Single Source Aerospace Fabrication and Manufacturing Solutions

Greengate Metal Components offers comprehensive aerospace metal fabrication solutions, acting as your single source from design to delivery.

With expertise in precision manufacturing, we manage every aspect of production, including material selection, cutting, welding, machining, and finishing. Our commitment to quality, efficiency, and innovation ensures each project meets the highest aerospace industry standards.

Contact Us

Why Choose Greengate Metal Components

With decades of experience, industry-leading certifications, and a commitment to precision and quality, GMC is your trusted partner for aerospace sheet metal fabrication. Our skilled engineers, advanced facilities, and customer-first approach provide reliable, cost-effective solutions for all your aerospace needs.

Decades of experience

Over 75 years of aerospace sheet metal fabrication knowledge.

Industry-leading certifications

ISO 9001:2015 certification for rigorous quality management.

Customer-first approach

Reliable, cost-effective solutions for aerospace projects.

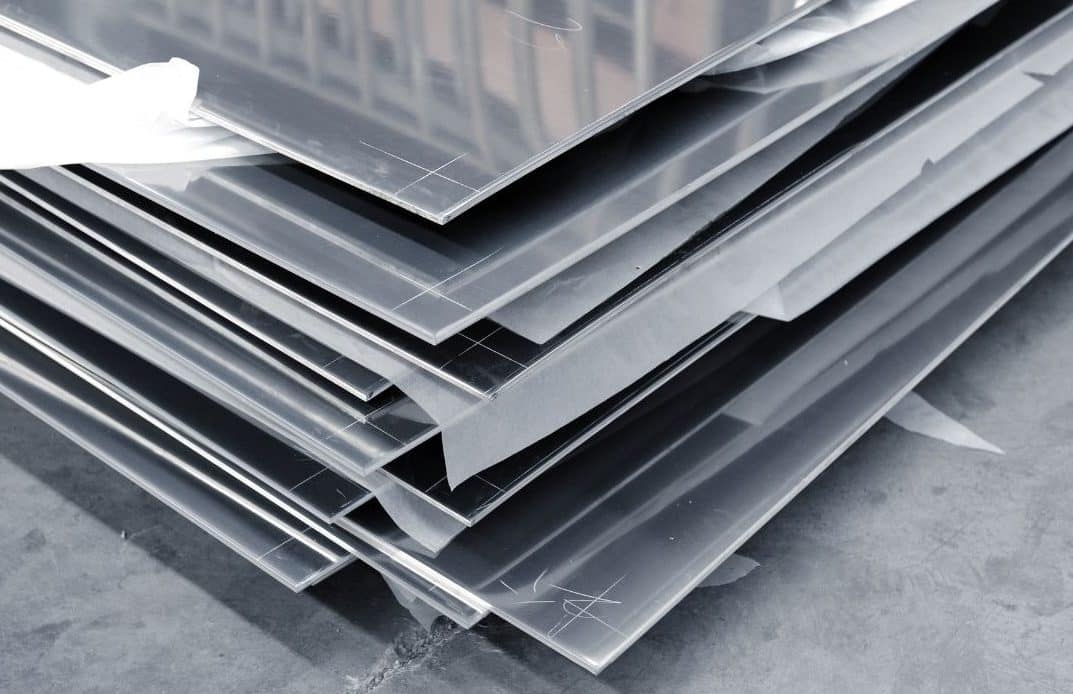

Materials We Work With For Aerospace Fabrication

We use only high-performance metals to meet the demanding standards of the aerospace industry.

Aluminium

Stainless Steel

Mild Steel

Titanium

Specialty Alloys

End to End Metal Manufacturing Solution

At Greengate Metal, we manage the entire manufacturing process for aerospace metal components, ensuring accuracy, durability, and a flawless finish. Our comprehensive service removes the need for multiple suppliers, simplifying production and delivering high-quality parts built to your exact specifications.

Our Machinery

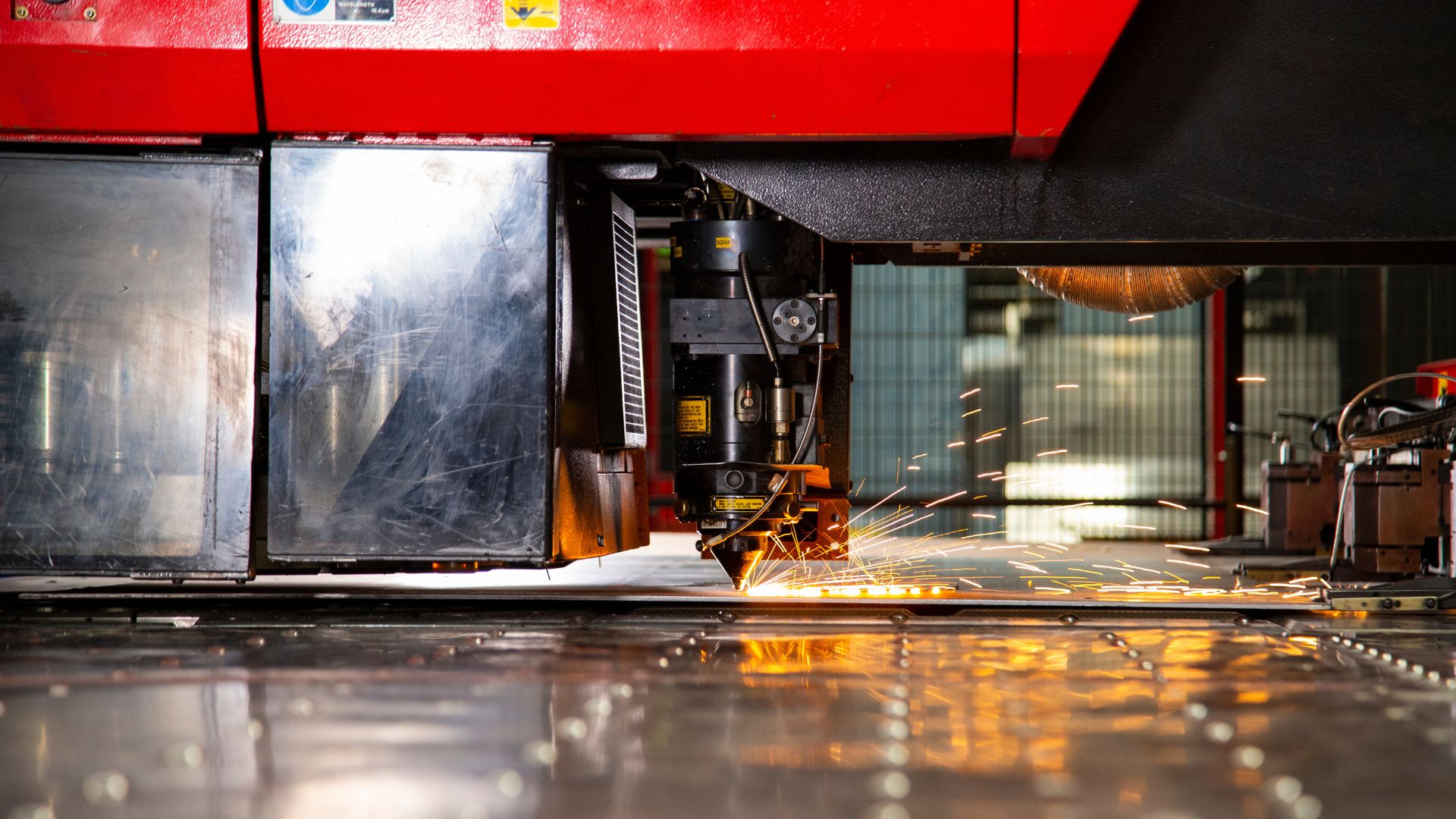

CNC Laser Cutting Machine

The VENTIS-AJ is a groundbreaking sheet metal cutting machine featuring next-generation fibre laser technology. Its revolutionary beam-shaping system ensures precise laser beam control. Powered by AMADA’s high-quality single diode module fibre laser engines, it comes in 4 kW and 6 kW versions. Despite lower power requirements, the 4 kW model performs like 6-8 kW machines, and the 6 kW model matches 8-10 kW machines, delivering exceptional cutting quality.

AMADA HFE3i

The AMADA HFE3i series represents the latest advancement in hydraulic press brakes. Building on the solid HFE foundation, it introduces productivity enhancements and a cutting-edge multi-touch screen interface. With high precision, it delivers top-quality batches, low energy costs, and exceptional process stability. It offers tailored bending solutions to meet specific needs, available in a wide range of sizes (50 tons, 1.2 m to 400 tons, 6 m) and customisable options.

AMADA EMX-3610

The EM-MII range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing. The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

Interested in Aerospace Metal Fabrication?

Choose Greengate Metal Components for precision and reliability. Contact us today to discuss your requirements.

Contact UsFrequently Asked Questions

Common materials used in kiosk and vending machine manufacturing include steel, aluminium, and stainless steel. Steel is widely chosen for its strength and durability, while aluminium is lighter, resistant to corrosion, and ideal for outdoor applications.

Stainless steel is highly durable and resistant to rust, making it perfect for high-traffic environments. The choice of material depends on factors such as location, climate, design requirements, and the need for protection against wear and tear.

Greengate Metal Components works with a range of materials tailored to the specific requirements of the aerospace industry. Common metals include:

- Aluminium: Lightweight and durable, ideal for reducing aircraft weight.

- Stainless Steel: Strong and corrosion-resistant for structural integrity.

- Speciality Alloys: Customised for specific performance needs, such as heat resistance and strength.

These materials are carefully selected and processed to provide maximum performance and longevity.

With over 75 years of industry expertise and advanced manufacturing capabilities, Greengate Metal Components is a trusted partner in aerospace sheet metal fabrication. The company offers:

- ISO 9001:2015 certification, giving you rigorous quality management.

- State-of-the-art facilities equipped with cutting-edge technology.

- An experienced team dedicated to delivering reliable, high-quality components that meet or exceed industry standards.

The company’s expertise and commitment to excellence ensure we can handle even the most complex fabrication projects.

Absolutely. We specialise in creating bespoke components tailored to exact aerospace requirements, capabilities include:

- Precise design and prototyping using CAD/CAM technology.

- Flexible manufacturing processes to meet unique specifications.

- Integration of customised components into aircraft systems.

No matter how complex the design, the company delivers flawless functionality and exceptional quality.

Greengate Metal Components offers a comprehensive range of aerospace sheet metal fabrication services, including:

- Design and prototyping with advanced CAD/CAM tools.

- Precision laser cutting and CNC punching for intricate patterns.

- Bending and forming to meet exact specifications.

- Welding and spot welding for durable assemblies.

- Surface finishing with protective coatings for enhanced durability.

- Product assembly, delivering components ready for immediate integration.

Greengate Metal Components manufactures components for a variety of aerospace applications, including:

- Aircraft seating and in-flight entertainment equipment.

- Cabin interiors, galleys, and stowages.

- Structural supports for fuselage and wings.

- Customised parts for specialised aerospace requirements.

With extensive experience, advanced facilities, and a commitment to quality, Greengate Metal Components is a leading provider of aerospace sheet metal fabrication solutions.