What is a Flat Pattern Development in Sheet Metal Fabrication?

Before any bending begins, a sheet metal part starts life as a 2D layout. That’s the flat pattern development. It’s...

Metalworking is an essential aspect of manufacturing, playing a major role in industries ranging from automotive to construction. Two widely used methods are metal machining and metal fabrication. While both processes are necessary for shaping and creating metal parts, they differ significantly in terms of technique, applications, and the type of projects they are suited for.

This article will clarify the differences between fabrication vs machining to help you make informed choices for your next project. We’ll cover everything from precision and costs to the types of industries that benefit most from each approach.

Metal machining is a subtractive process where the material is cut or removed from a solid metal workpiece to achieve the desired shape or dimensions. This is typically done using tools such as lathes, mills, and drills. One of the standout features of machining is the use of Computer Numerical Control (CNC) machines, which bring a high level of precision and enable the creation of complex shapes with tight tolerances.

Machining techniques include turning, where a cutting tool moves along the surface of a rotating workpiece; milling, which involves rotating cutters to shape the metal; and drilling, used to create precise holes. Industries like automotive, aerospace, and electronics rely on machining for its ability to handle detailed work and its flexibility with various metals.

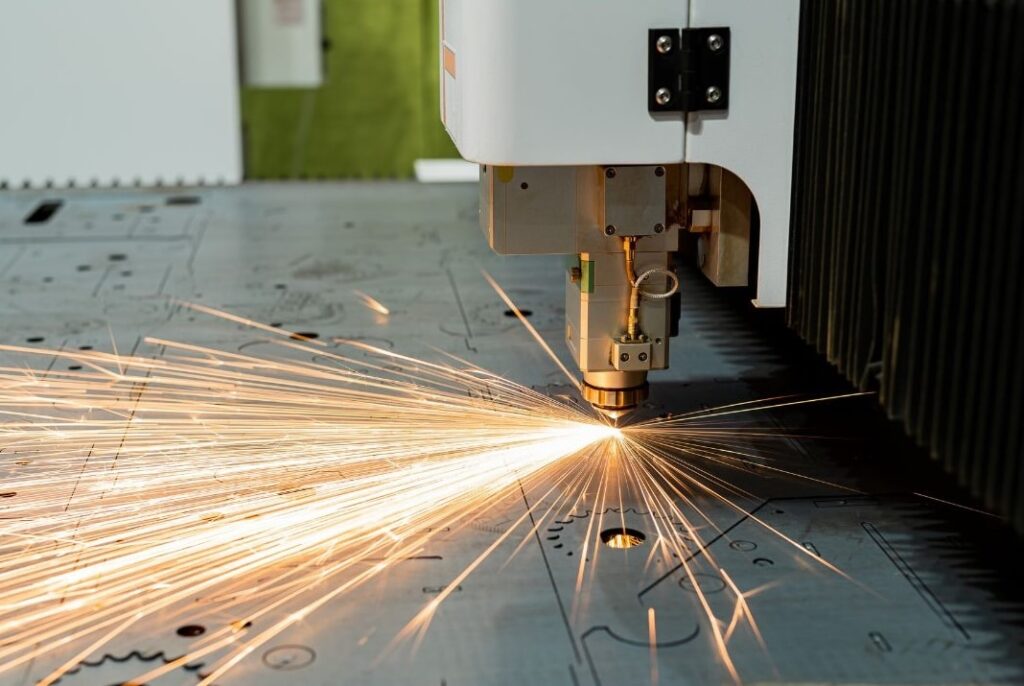

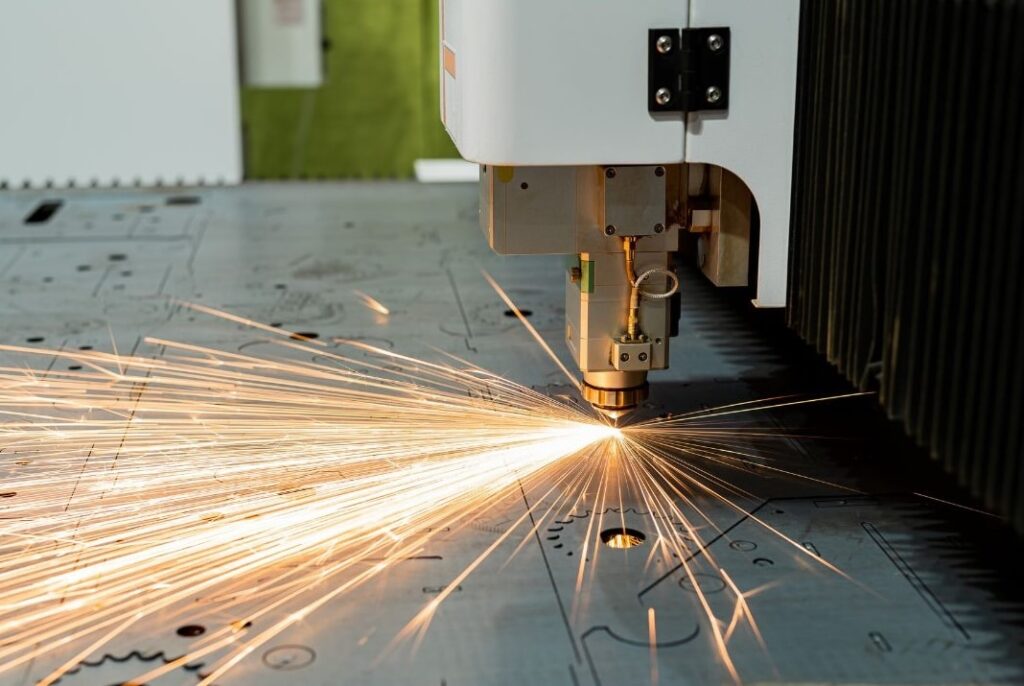

Metal fabrication involves assembling, shaping, and constructing metal parts or structures from raw materials. The methods commonly used include welding, cutting, and bending. Unlike machining, which focuses on cutting away material, fabrication generally involves shaping and joining metal components.

Fabrication is often used for larger projects, such as building structures or heavy equipment. It’s also highly versatile—fabrication can be customised to specific design requirements or used for mass production, depending on the scope of the project. The fabrication process is widely applied in industries like construction, architectural metalwork, and heavy machinery, where durability and structural integrity are paramount.

The processes of metal machining and fabrication differ significantly in how they handle the raw materials.

In metal machining, the process begins with selecting a solid piece of metal known as a workpiece. This material is shaped by cutting tools like lathes, mills, and drills, often controlled by CNC machines for greater accuracy. The machining process typically involves multiple stages, including material removal, shaping, and final touches to achieve the required form and surface quality.

On the other hand, metal fabrication starts with sheets, tubes, or metal bars. These raw materials are cut, shaped, and assembled using methods like welding, bending, and cutting. Fabrication often involves joining multiple components to form larger structures, especially in large-scale projects. The process concludes with treatments like coating to protect the metal and enhance its appearance.

Precision is a factor in both machining and fabrication. CNC machining allows for extremely tight tolerances, hence why it’s preferred for projects requiring detailed and exact dimensions. Industries like aerospace and automotive benefit from machining’s high precision, where accuracy can mean the difference between success and failure.

While metal fabrication can achieve good precision, it generally doesn’t match the tight tolerances of machining. The processes of welding and bending can produce accurate results but are more focused on structural integrity than fine detail. This makes fabrication better suited for larger projects where strength is more needed than precision.

Material waste is another big consideration when choosing between machining and fabrication.

In metal machining, material is gradually cut away from the workpiece, resulting in significant waste in the form of metal chips. However, many manufacturers use advanced software and CNC machines to optimise material usage and reduce waste. Additionally, recycling programs help manage the environmental impact by reclaiming metal for reuse.

Fabrication tends to produce less waste, as the process involves shaping and assembling pre-cut metal pieces. However, offcuts from large metal sheets or bars can still result in scrap material. Techniques like CNC plasma cutting and precise planning can help minimise these offcuts, contributing to more efficient and environmentally friendly fabrication practices.

Production speed varies considerably between the two methods. Metal machining can be time-consuming, especially for intricate parts requiring multiple stages of cutting and finishing. Although CNC machines can automate and speed up some aspects of machining, the process still tends to be slower than fabrication when complex shapes and high precision are needed.

Fabrication, on the other hand, is often faster, especially for projects involving larger, simpler parts or assemblies. Processes like welding, cutting, and bending can be completed more quickly than the detailed shaping involved in machining. For businesses needing rapid turnaround times for large structures, fabrication is generally the more efficient choice.

Machining tends to be more expensive due to the advanced machinery and precision required, especially for complex parts. Projects with intricate designs or tight tolerances drive up costs due to longer production times and specialised tooling. However, machining becomes more cost-effective in bulk production, as setup costs are spread across larger quantities.

Fabrication is typically more affordable, especially for simpler projects. However, costs can increase significantly for custom or multi-stage fabrication, such as welding and assembling complex structures. Evaluating both the size and complexity of a project is required to balance quality with cost efficiency.

Both machining and fabrication serve major roles in different industries. Machining is ideal for sectors like aerospace, automotive, and electronics, where precision and detail are required. Parts such as gears, engine components, and circuit boards often rely on machining for their production.

Fabrication, on the other hand, is better suited for large-scale projects like construction, architectural designs, and heavy equipment manufacturing. Products like metal frames, staircases, and building facades typically require the strength and durability that fabrication offers. Sometimes, both methods are used together; for instance, a project may involve fabricating a frame and machining smaller components for assembly.

The skills required for machining and fabrication differ due to the nature of the work. Machinists need a high level of technical skill, particularly in operating CNC machines and understanding precise design specifications. The training often includes apprenticeships or vocational courses, focusing on both manual and computer-aided machining tools.

Fabricators, in contrast, rely more on practical skills like welding, cutting, and bending. Welding, in particular, is a highly specialised skill that involves joining metal parts under heat and pressure. Both fields require a combination of hands-on experience and technical knowledge to provide high-quality results.

Both machining and fabrication offer distinct advantages depending on your project’s needs. Machining is ideal for precision-focused tasks, while fabrication excels in larger, structural projects.

When deciding between the two, consider factors like precision, cost, speed, and waste to ensure you choose the right process for your project. Understanding these differences helps you make the most informed decision for your business.

For more information, contact us at Greengate Metal Components—the name you can count on when quality counts.

Before any bending begins, a sheet metal part starts life as a 2D layout. That’s the flat pattern development. It’s...

Most sheet metal design errors don’t happen during production — they start earlier, in planning or communication. Maybe it’s the...

While Numerical Control (NC) has been around for decades, Computer Numerical Control (CNC) continues to reshape how precision parts get...