Benefits of Outsourcing Medical Component Metal Fabrication

- Cost savings

- Access to expertise

- Scalability and flexibility

- Faster time-to-market

- Focus on core business activities

Bespoke Cabinet and Enclosure Metal Solutions

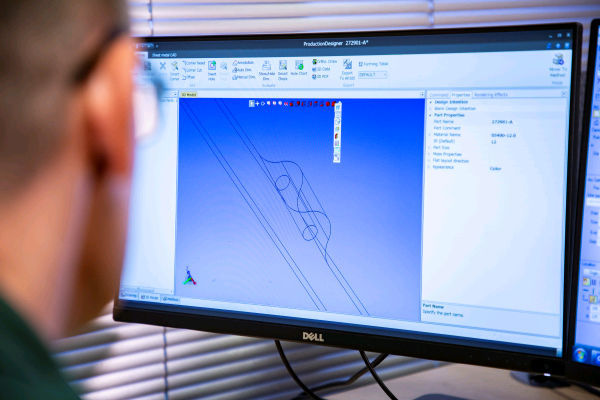

At Greengate Metal Components, we use advanced CNC laser cutting technology to deliver precise and efficient metal enclosure fabrication for the switchgear industry.

Our laser cutting ensures each piece is cut with accuracy, allowing us to produce intricate shapes and designs from a range of materials. Whether it’s steel, aluminium, or stainless steel, our CNC machines provide exceptional precision, ensuring top-quality results for your switchgear enclosures.

We Have The Expertise and Experience To Help

At Greengate Metal Components, we bring over 75 years of experience in sheet metal fabrication to deliver high-quality, durable components across various industries.

We understand the challenges of creating reliable, robust parts for demanding applications. Our team collaborates closely with you during the design and engineering phases, offering valuable insights to optimise component performance, reduce production costs, and improve manufacturability, ensuring your systems are built to the highest standards.

End to End Metal Manufacturing Solution

At Greengate Metal, we handle every stage of the manufacturing process, ensuring precision, consistency, and efficiency from start to finish. Our end-to-end service means you get high-quality metal components without the hassle of coordinating multiple suppliers.

Interested in Cabinet and Enclosure Sheet Metal Fabrication?

Contact us today to discuss your requirements and find out how we can help.

Our Machinery

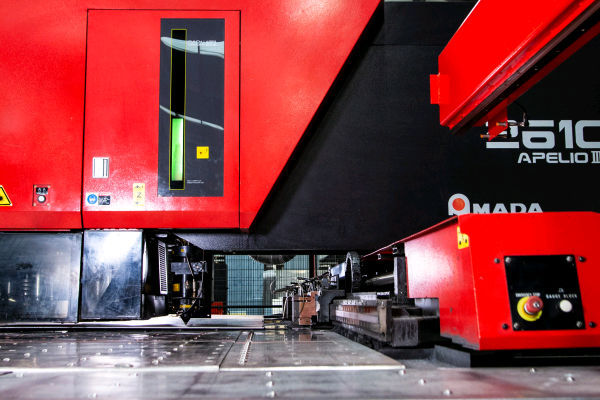

CNC Laser Cutting Machine

AMADA HFE3i

AMADA EMX-3610

The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

Frequently Asked Questions

Common materials for metal cabinet and enclosure fabrication include steel, aluminium, and stainless steel.

Steel is a popular choice due to its strength and affordability, while aluminium offers a lightweight yet durable option with excellent corrosion resistance.

Stainless steel is ideal for environments where corrosion resistance is critical, as it provides enhanced durability in harsh conditions. The choice of material depends on the specific application, environmental factors, and performance requirements, such as for electrical systems or outdoor installations.

CNC laser cutting enhances metal cabinet fabrication by providing precision and speed. This technology uses focused laser beams to cut metal sheets with high accuracy, creating intricate shapes and designs without the need for traditional tooling.

The result is a smooth, clean edge with minimal distortion, improving the overall quality of the finished product. This method allows for rapid production of custom components, reducing lead times and ensuring that complex designs can be achieved consistently.

In the switchgear industry, metal enclosures are important for protecting electrical components and systems. These enclosures safeguard switchgear equipment from external factors like dust, moisture, and physical damage, ensuring optimal performance and longevity.

Enclosures also provide safety by preventing access to high-voltage parts, reducing the risk of electrical hazards. Metal cabinets and enclosures for switchgear applications must meet specific industry standards for durability, fire resistance, and environmental protection, ensuring reliable operation in demanding environments.

At Greengate Metal Components, we maintain strict quality control throughout the entire fabrication process. We utilise state-of-the-art equipment, including CNC laser cutting and precision welding, to produce components that meet the highest standards.

Our team of experienced engineers ensures that all designs undergo testing and inspection, from the initial prototype to final production. Additionally, we work closely with our clients to meet specific requirements, ensuring that every metal enclosure is durable, reliable, and fit for purpose.

Outsourcing metal enclosure fabrication allows companies to focus on their core business activities while leaving the complexities of production to experts. This approach provides access to advanced technologies, such as CNC laser cutting and welding, without the need for significant capital investment in machinery.

By partnering with an experienced manufacturer, businesses can achieve high-quality, custom enclosures, faster turnaround times, and reduced production costs.

Metal cabinet and enclosure fabrication serves a wide range of industries, including telecommunications, industrial automation, electrical systems, and renewable energy.

In these industries, enclosures protect critical components such as circuit boards, electrical wiring, and control systems from environmental factors, physical damage, and electrical hazards.

Additionally, sectors like transportation, manufacturing, and healthcare rely on robust enclosures to safeguard sensitive equipment.