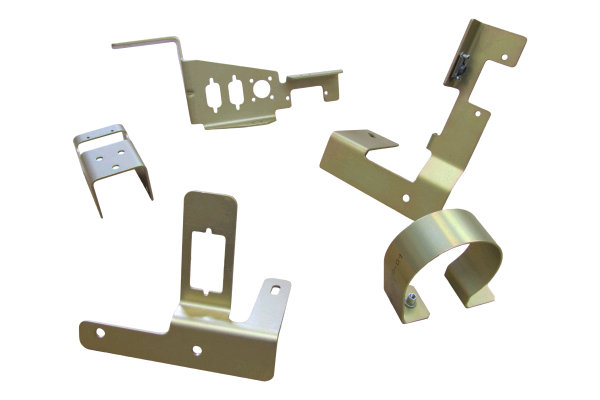

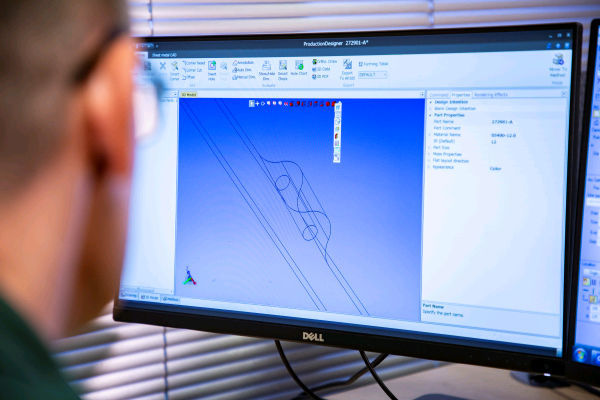

Sheet Metal Bending & Forming

Contact Us

Our Capabilities

Materials We Work With

- Mild Steel

- Stainless Steel

- Aluminium

- Zintec / Galvanised Steel

- Copper

- Brass

- Coated Sheets

Metal Thickness

- Mild Steel: Up to 10mm

- Stainless Steel: Up to 10mm

- Aluminium: Up to 10mm

- Brass: Up to 10mm

- Copper: Up to 10mm

Part Sizes

- Up to 4000mm

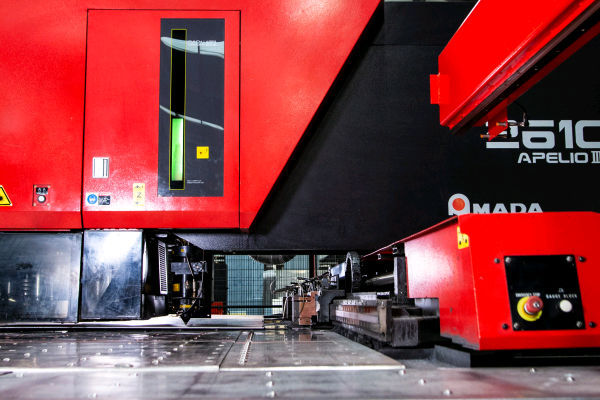

Our Machinery

AMADA HFE3i

The AMADA HFE3i series are the latest evolution in hydraulic drive press brakes. Designed with the solid characteristics of the HFE series, the 3i series features new additions to improve productivity, as well as, a highly innovative multi-touch screen interface. The processing precision enables the production of very high quality sheet metal bending batches, at low energy costs and with an unrivalled process stability. The extensive range of sizes (from 50 tons, 1.2 m to 400 tons, 6 m) and options mean that customers can configure the ideal metal bending solution for their specific needs.