CNC Metal Laser Cutting

Contact Us

Our Capabilities

Materials We Laser Cut

- Mild Steel

- Stainless Steel

- Aluminium

- Zintec / Galvanised Steel

- Copper

- Brass

- Coated Sheets

Metal Thickness

- Mild Steel: 0.5mm-25mm

- Stainless Steel: 0.5mm-20mm

- Aluminium: 0.5mm-16mm

- Brass: 0.5mm-10mm

- Copper: 0.5mm-8mm

Sheet Sizes

- Up to 3000 x 1500mm

More Reasons to choose Greengate Metal Components?

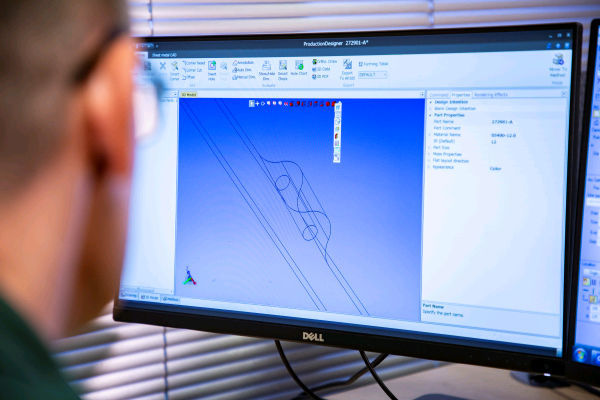

The Laser cutting machinery and software we use also allows for maximum material utilisation. A very narrow cut width on the laser & optimal nesting of sheet metal parts, ensures the absolute maximum number of components per sheet. Resulting in minimal wastage, maximum efficiency and lower material costs for our customers. Greengate Metal Components can handle material sheet size up to 4 x 1.5meters.

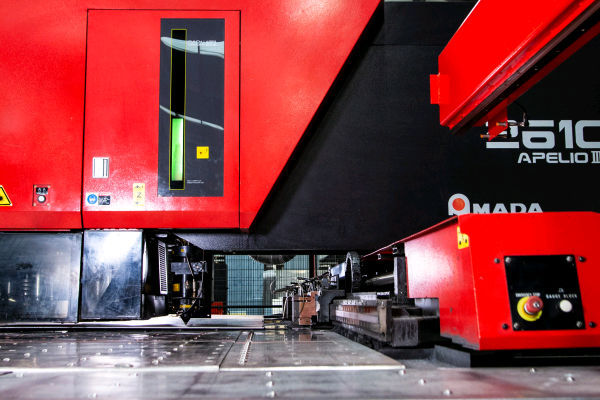

Alongside standalone laser cutting, Greengate Metal Components also offers CNC punch/laser combination machines. These machines can punch, form and laser cut sheet metal on the same equipment. This allows Greengate Metal Components to complete all of these processes without the need to change machine operation, maximising efficiency. To supplement these machines Greengate Metal Components operates fully automatic loading and unloading equipment allowing for full automation and 24hr operation. Giving our customers shorter lead times.

Our Machinery

Ventis-AJ Fibre Laser