How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

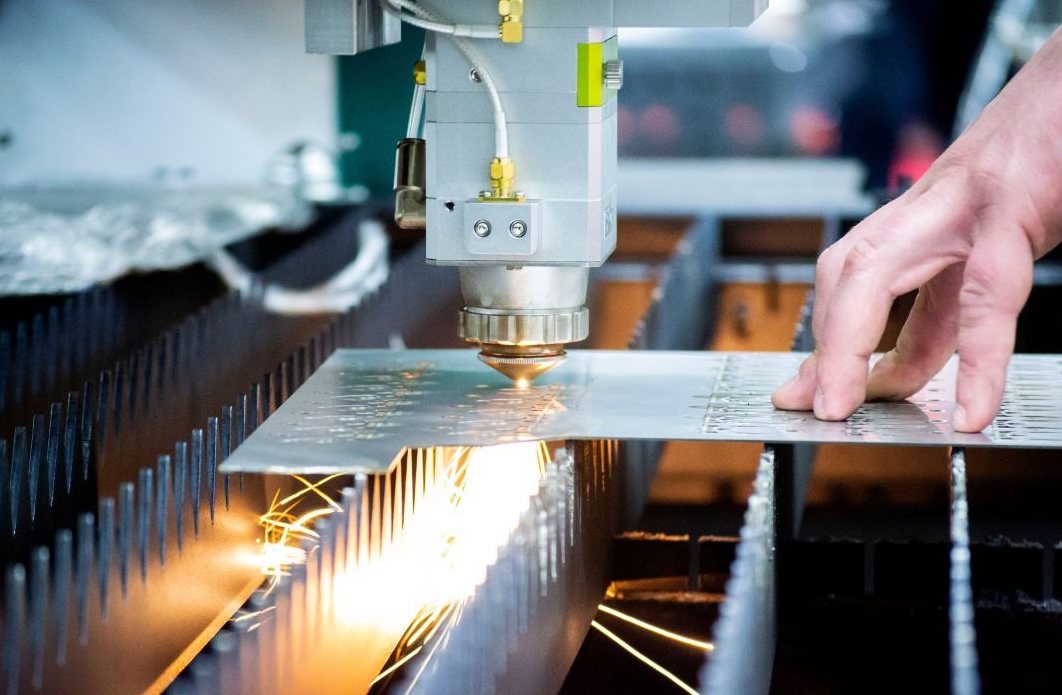

Metal laser cutting might sound like something overly complex, yet it’s actually a fairly neat way to get clean, repeatable results when shaping sheet metal.

It’s often used when other methods simply don’t deliver the level of detail or consistency required. Whether you’re working on early-stage prototypes or short-run production parts, laser cutting accuracy tends to be the thing most engineers and designers are asking about.

Precision laser cutting isn’t just about sharp edges – it’s about how closely a part matches the design, every single time. With CNC laser cutting services in particular, consistency and control are more or less built in. For anyone working with sheet metal, laser cutting explained in clear terms reveals why it’s become such a trusted option.

The rest of this article unpacks how it works, what affects its accuracy, and how to spot the most accurate cutting methods out there.

Laser cutting uses a highly focused beam of light to heat and melt through metal, but that’s only part of the picture. The real accuracy comes from how tightly that beam is controlled. Most systems today use CNC laser cutting, which means the laser’s path follows computer-guided instructions to the exact coordinates of your design file.

As the laser head moves across the sheet, assisted by either gas or air pressure, it makes fast, precise cuts without touching the material. That’s why there’s little mechanical stress, and why fine features are usually no trouble at all. This method is ideal for everything from steel and aluminium to more specialist metals.

Accuracy isn’t just about the beam, though – it’s also about how the machine handles each movement, especially across tight curves or corners. In that sense, sheet metal laser cutting is less prone to distortion than manual or traditional techniques, which means cleaner results and tighter laser cut tolerances, right from the start.

So, laser cutting accuracy isn’t a fixed number – it depends on a mix of variables that, when handled properly, make all the difference. Here’s a quick look at the ones that really matter:

Even with advanced machines and careful planning, a few things can still throw off laser cutting accuracy. Understanding these helps when you’re weighing up suppliers or planning production runs.

So, once a part is cut, how do you actually know it’s accurate? That’s where measurement tools and quality checks come in. Most providers use a mix of manual and digital equipment – for instance, precision callipers for simple checks, or coordinate measuring machines (CMMs) for parts that need more detailed inspection.

Laser cut tolerances are usually set during the design phase. These tell the machine – and the inspection team – how close the final part needs to be to the drawing. Tighter tolerances often mean slower cutting speeds and more detailed verification, but they’re essential for components that fit into complex assemblies.

What really makes a difference, though, is working with a provider who’s done this all before. Experience counts when it comes to spotting potential issues early, whether it’s a design that needs tweaking or a material that reacts differently than expected. With a process like precision laser cutting, small adjustments often separate a decent part from a perfect one.

For anyone working on prototypes or short production runs, laser cutting offers a mix of speed, quality and consistency that’s hard to beat. Here are a few reasons it’s become such a go-to:

Accuracy in laser cutting isn’t just possible – it’s pretty much expected, especially with the right setup and experience behind the controls. For engineers and designers who rely on precision from the first cut to the last, it’s often the safest bet.

At Greengate Metal Components, we don’t just meet tight tolerances, we treat them as standard. That’s what keeps our clients coming back.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...