How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

Not every project starts with a blueprint, but the smart ones usually do. If you’re planning a custom metal component or structure, adding a CAD drawing to the mix isn’t just sensible – it’s more or less non-negotiable. So, why’s that?

A CAD drawing brings certainty to a process that can otherwise be, well, a little murky. With a clear digital model in place, everything from dimensions to tolerances can be agreed on before a single piece of metal is touched. That’s the sort of reassurance your production line – and your bottom line – might be crying out for.

This article cuts through the noise. It lays out how Computer-Aided Design fits neatly into metal fabrication services, the planning process and why it’s a better move now than an afterthought later.

Let’s be honest — getting things wrong by even a millimetre can cause no end of trouble later. That’s where CAD drawings for fabrication really come into their own. They strip the guesswork out of the process, replacing hasty sketches or vague outlines with pin-sharp detail.

With CAD, what you see is what you actually get. Dimensions are locked in. Tolerances aren’t ballpark figures – they’re exact. So when it’s time to cut, bend or fold, there’s no second-guessing. Everything fits the way it’s meant to, from the first component to the last.

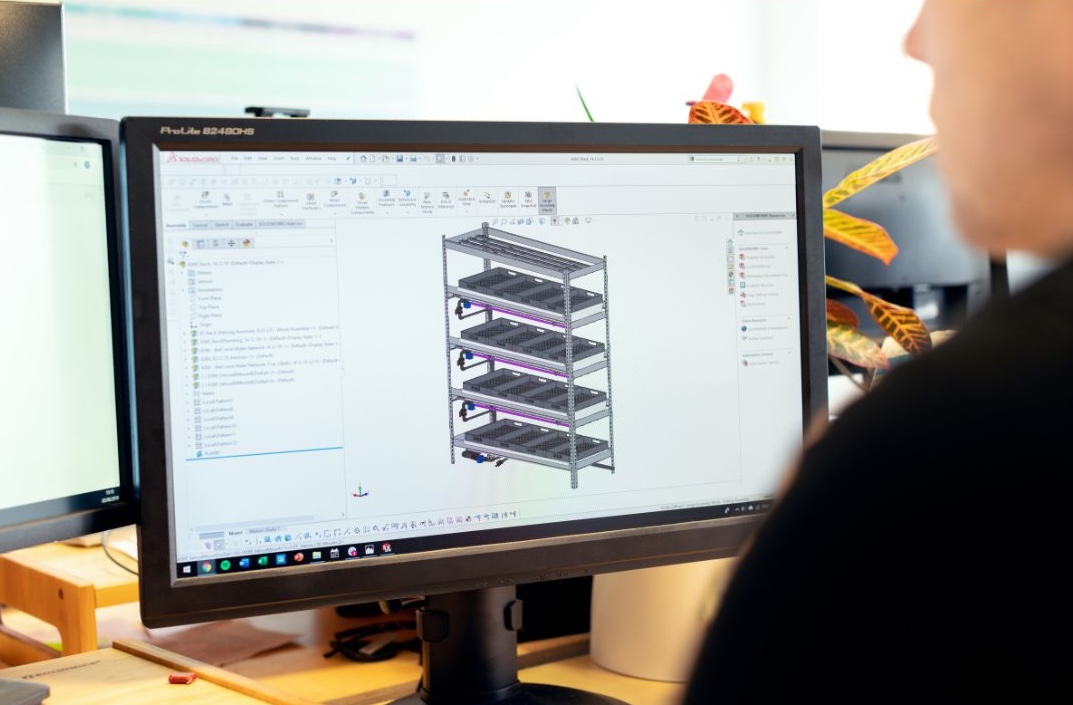

This sort of digital precision isn’t just clever – it’s essential if you’re using CNC. The machine reads the CAD file, interprets every line and curve, and gets to work. The result? Consistently accurate metal parts that do the job they were built for, every single time.

That level of reliability isn’t just nice to have. It’s the sort of thing that keeps projects on track, engineers off the phone, and fabricators out of the rework pile. In short, CAD benefits everyone involved.

Time’s tight more often than not. And if you’re up against a deadline, CAD drawings could be the difference between pushing forward and pushing your luck. They speed things up at just about every stage, especially when prototyping’s involved.

Instead of fiddling with manual drawings or tweaking measurements by hand, everything gets handled digitally. Change a radius, shift a cut-out, test a new bracket — it’s all just a few clicks away. That kind of prototyping efficiency is hard to ignore, particularly when it means less downtime and fewer snags on the shop floor.

Once the design’s signed off, production ramps up fast. The CAD file feeds straight into CNC machines, meaning there’s virtually no time wasted converting plans or translating sketches. It’s a smooth handover from idea to execution.

For projects that can’t afford delays — and frankly, most can’t — this streamlined setup makes all the difference. So, whether you’re tweaking a prototype or kicking off a full production run, CAD drawings for fabrication help you stay ahead instead of playing catch-up.

Wasted material doesn’t just hurt the environment — it chips away at your budget too. That’s where CAD drawings quietly pull their weight. From the start, they help you spot issues that could become expensive later. Fewer surprises mean fewer do-overs, and that’s where the real CAD cost savings start to show.

In most cases, a CAD file allows the fabricator to plan cuts and folds more efficiently. By nesting components on sheet metal digitally, it’s possible to make better use of every inch, rather than leaving gaps that end up in the scrap bin. Over multiple parts, or even multiple projects, those savings stack up quickly.

Then there’s rework — or rather, the lack of it. With a detailed CAD drawing guiding production, it’s far less likely that something gets misread or misaligned. That reduces the chance of needing costly corrections or re-machining.

CAD also allows for better use of advanced tools like laser cutting capabilities, where precision layouts really pay off. It should be built into your metal fabrication planning, not treated as a luxury or a maybe.

Things change — a bolt needs repositioning, a panel needs resizing, or maybe the whole spec shifts mid-project. Without a CAD drawing, those changes can mean starting again. But with one? It’s more like tweaking than tearing up the plans.

Digital files are, in a way, built for change. You can update dimensions, shift features or swap materials without redrawing everything from scratch. That sort of flexibility matters, especially in custom metal design, where the end result isn’t always obvious from day one.

This is particularly handy when scaling a project. Let’s say the prototype worked well, and now it’s time for a full run. Instead of re-creating the design, you adjust the original CAD file, saving time and cutting out extra admin.

So whether the project’s moving forward, shifting sideways, or just slightly changing direction, CAD handles it without fuss. It makes updates more manageable, less messy and, frankly, a lot cheaper than doing it all over again.

It’s one thing to have a great design — it’s another to make sure the person building it actually sees the same thing you do. CAD drawings help close that gap. They give everyone involved a shared, visual reference point that leaves much less room for crossed wires or costly assumptions.

For design teams and fabricators working together, that sort of clarity really matters. It stops mistakes before they happen. Whether it’s a chamfered edge or a fold tolerance, it’s all there on the screen — clearly laid out, easy to interpret.

This is where the cad benefits often go under the radar. It’s not just about machines and measurements. It’s about improving how people work together to get accurate metal parts made without all the back-and-forth.

Here’s what better collaboration through CAD can look like:

CAD drawings aren’t just helpful – they’re more or less the glue that holds a fabrication project together. From clear specs to fewer mistakes, the gains are hard to ignore. Engineers, designers and fabricators all end up speaking the same language, which, frankly, makes the whole process smoother. At Greengate Metal Components, we treat CAD like a must-have, not a maybe, and it shows in every finished part.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...