Pharmaceutical & Medical Metal Fabrication

What Is Pharmaceutical & Medical Metal Fabrication?

As the pharmaceutical and medical industries evolve, the demand for precision-engineered components grows ever greater. Sheet metal fabrication is at the heart of producing everything from laboratory equipment to medical device enclosures, ensuring reliability and hygiene in critical applications.

With the rise in advanced therapies, stricter regulatory standards, and the push for innovative technologies, sheet metal is indispensable in manufacturing durable, high-quality solutions that meet the exacting requirements of modern healthcare.

Contact UsMedical and Pharmaceutical Metal Components We Can Manufacture

Outsource Medical Sheet Metal Fabrication

Outsourcing sheet metal fabrication for pharmaceutical and medical applications is a smart move for businesses aiming to deliver high-quality components without the challenges of managing in-house production.

Outsourcing to fabrication specialists, such as Greengate Metal Components, shortens production timelines while ensuring compliance with strict regulatory standards. In a sector driven by advancing technology, strict hygiene requirements, and the need for rapid innovation, partnering with a trusted manufacturer enables you to stay ahead, delivering reliable solutions that enhance the performance and safety of medical and pharmaceutical systems.

Our Services

At Greengate Metal Components, we offer a complete range of sheet metal fabrication services for the pharmaceutical and medical sectors.

Sheet Metal Fabrication

Stainless Steel Fabrication

Aluminium Fabrication

Copper Fabrication

Mild Steel Fabrication

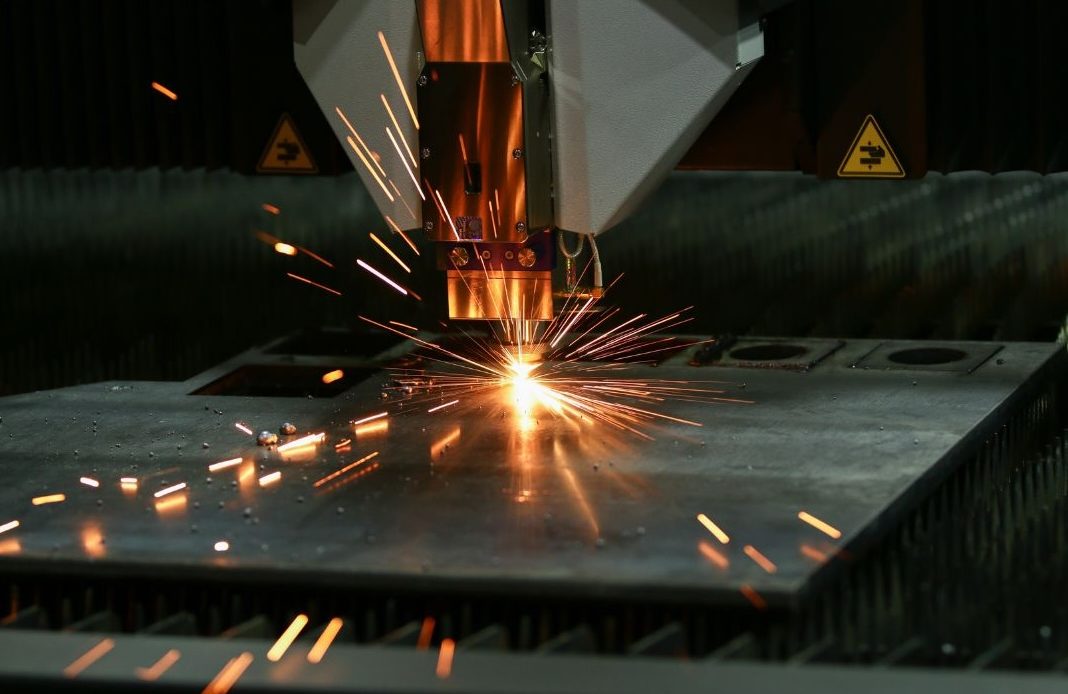

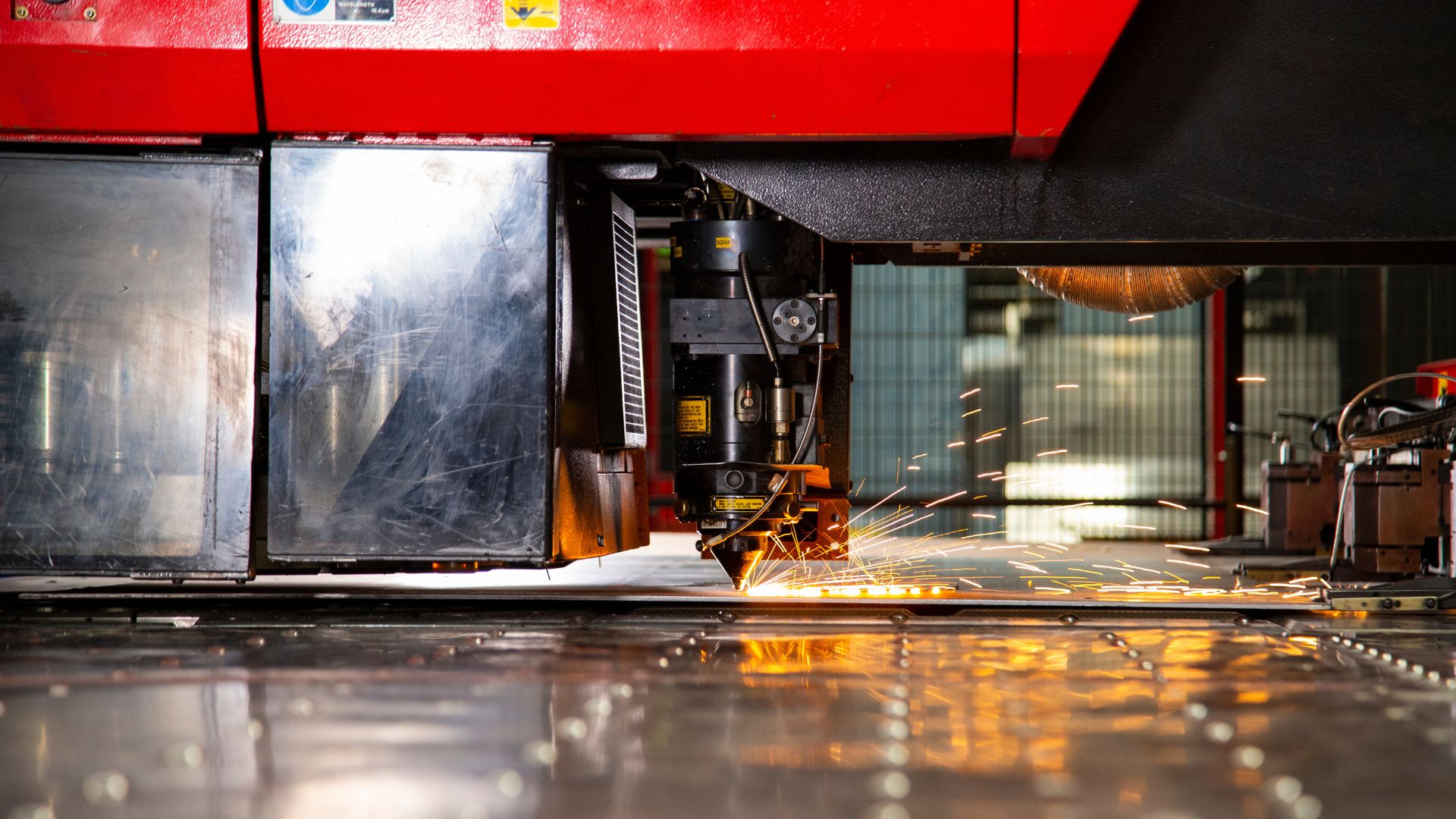

CNC Metal Laser Cutting

CNC Metal Punching

Sheet Metal Assembly

Benefits of Outsourcing Medical Component Metal Fabrication

Cost savings

Reduce overheads associated with in-house production equipment, staffing, and maintenance.

Access to expertise

Benefit from decades of specialised sheet metal fabrication experience in medical and pharmaceutical applications.

Scalability and flexibility

Scale from prototypes to volume production without investing in extra capacity.

Faster time-to-market

Accelerate lead times with streamlined processes focused on medical and pharmaceutical components.

Focus on core business activities

Free internal teams to concentrate on innovation, research, and patient care while fabrication is handled by specialists.

Bespoke Metal Solutions for the Medical Industry

At Greengate Metal Components, we use advanced CNC machinery to deliver high-quality and efficient metal component fabrication.

With our advanced laser-cutting technology, we can create highly accurate and detailed designs bespoke to the unique needs of the medical and pharmaceutical industries. We work with materials like steel, aluminium, and stainless steel to deliver exceptional results. Precision is critical in healthcare, and our CNC machines ensure every piece meets the highest standards for quality and reliability.

End to End Manufacturing

We offer a fully integrated service, handling every stage of production in-house. Our expertise spans laser cutting, CNC machining, welding, and assembly, delivering finished products that are ready for immediate use in critical healthcare applications. Whether you require single prototypes or large-scale production, our facilities are equipped to deliver with speed and precision.

Interested in Medical and Pharmaceutical Sheet Metal Fabrication?

Contact us today to discuss your requirements and find out how we can help.

Contact Us

We Have The Experience and Knowledge To Help

At Greengate Metal Components, we’ve spent over 75 years perfecting the art of sheet metal fabrication, helping the medical and pharmaceutical industries create high-quality, reliable components.

We know how important it is to produce parts that are precise, durable, and meet strict hygiene standards. That’s why we work closely with you from the very start, offering practical advice to improve performance, simplify production, and keep everything compliant with industry regulations.

Our Machinery

CNC Laser Cutting Machine

The VENTIS-AJ is a groundbreaking sheet metal cutting machine featuring next-generation fibre laser technology. Its revolutionary beam-shaping system ensures precise laser beam control. Powered by AMADA’s high-quality single diode module fibre laser engines, it comes in 4 kW and 6 kW versions. Despite lower power requirements, the 4 kW model performs like 6-8 kW machines, and the 6 kW model matches 8-10 kW machines, delivering exceptional cutting quality.

AMADA HFE3i

The AMADA HFE3i series represents the latest advancement in hydraulic press brakes. Building on the solid HFE foundation, it introduces productivity enhancements and a cutting-edge multi-touch screen interface. With high precision, it delivers top-quality batches, low energy costs, and exceptional process stability. It offers tailored bending solutions to meet specific needs, available in a wide range of sizes (50 tons, 1.2 m to 400 tons, 6 m) and customisable options.

AMADA EMX-3610

The EM-MII range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing. The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

Frequently Asked Questions

We offer comprehensive sheet metal fabrication services, including laser cutting, CNC machining, welding, and assembly. Our expertise lies in producing precision-engineered components for equipment like medical enclosures, laboratory devices, and cleanroom furniture. With over 75 years of experience, we work with materials such as stainless steel and aluminium to meet strict hygiene and quality standards essential in healthcare and pharmaceutical applications.

Sheet metal fabrication ensures the production of durable, hygienic, and highly accurate components essential for medical devices, pharmaceutical equipment, and cleanroom environments. Our precision techniques at Greengate Metal Components ensure compliance with industry regulations while providing reliable solutions that support safety, innovation, and patient care.

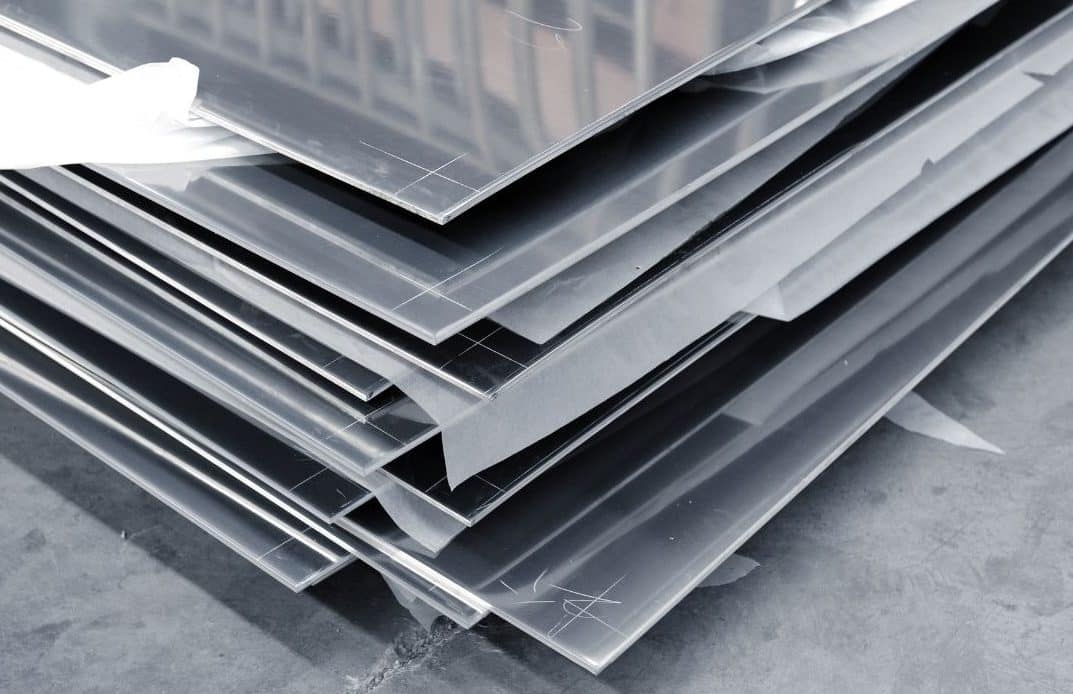

We work with a variety of materials, including stainless steel, aluminium, and mild steel. Stainless steel is particularly popular due to its corrosion resistance and ease of cleaning, making it ideal for sterile environments.

Yes, we specialise in bespoke fabrication solutions to meet your exact specifications. From prototypes to large production runs, our team works closely with you during the design and engineering phases to deliver components that meet your unique needs while optimising manufacturability and cost efficiency.

Outsourcing saves you time and resources, allowing you to focus on core business activities. At Greengate Metal Components, we offer expert guidance, precision manufacturing, and efficient production timelines, ensuring your components are made to the highest standards without the need to manage in-house fabrication.

With over 75 years of experience, we bring unmatched expertise to every project. We prioritise precision, hygiene, and compliance, using advanced technology to deliver high-quality, bespoke solutions. Our commitment to customer service ensures you receive tailored support and reliable results, making us a trusted partner for the medical and pharmaceutical industries.