Kiosk and Vending Manufacture & Assembly

What Is Kiosk and Vending Manufacture & Assembly?

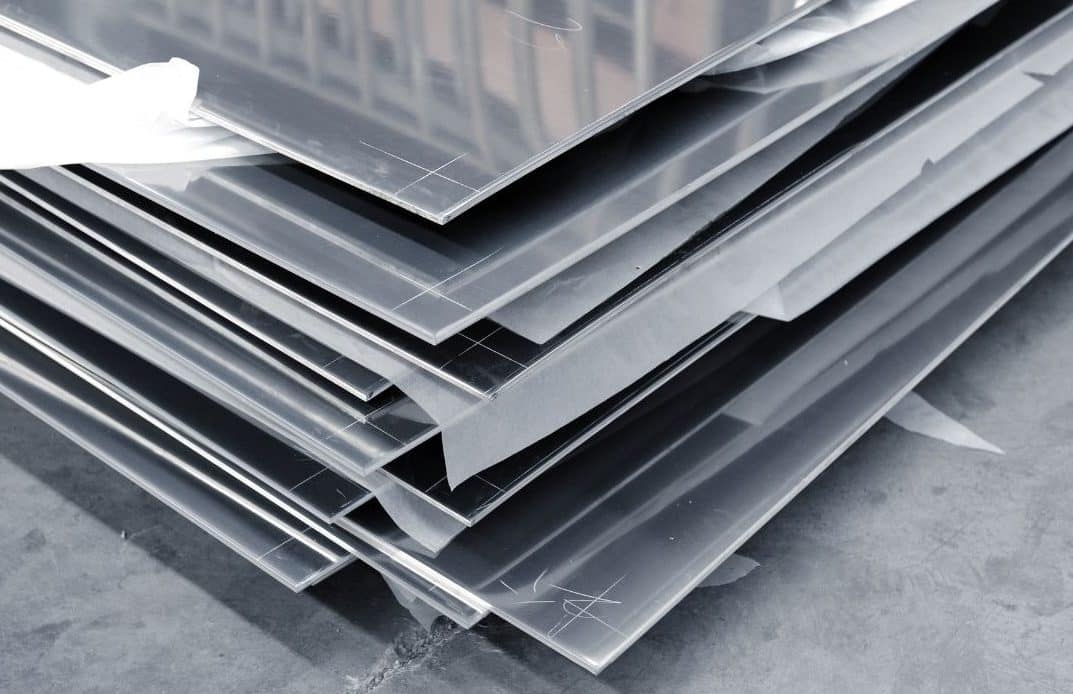

As the kiosk and vending machine industry evolves, the demand for reliable, durable components increases. Sheet metal fabrication plays a key role in producing machine enclosures and parts that endure heavy use in public spaces.

Outsourcing fabrication has become crucial, allowing businesses to reduce costs, access specialised skills, and speed up production. With growing demand for innovative, high-quality machines, outsourcing ensures companies can meet these needs effectively and stay competitive.

Contact UsKiosk and Vending Metal Components We Can Manufacture

Outsource Kiosk and Vending Metal Fabrication

Outsourcing sheet metal fabrication for the kiosk and vending machine industry helps companies provide high-quality, reliable components without the hassle of in-house production.

Working with specialists speeds up production, ensuring precision and efficiency while meeting industry standards for durability. With technology and customer demands constantly changing, partnering with a trusted manufacturer helps businesses stay competitive, delivering strong, long-lasting solutions that improve the performance and reliability of kiosks and vending machines.

Our Services

Sheet Metal Fabrication

Stainless Steel Fabrication

Aluminium Fabrication

Copper Fabrication

Mild Steel Fabrication

CNC Metal Laser Cutting

CNC Metal Punching

Sheet Metal Assembly

Benefits of Outsourcing Kiosk and Vending Component Fabricating

Cost savings

Cost savings

Access to expertise

Access to expertise

Scalability and flexibility

Scalability and flexibility

Faster time-to-market

Faster time-to-market

Focus on core business activities

Focus on core business activities

Tailored Metal Solutions for Kiosk and Vending Manufacturing

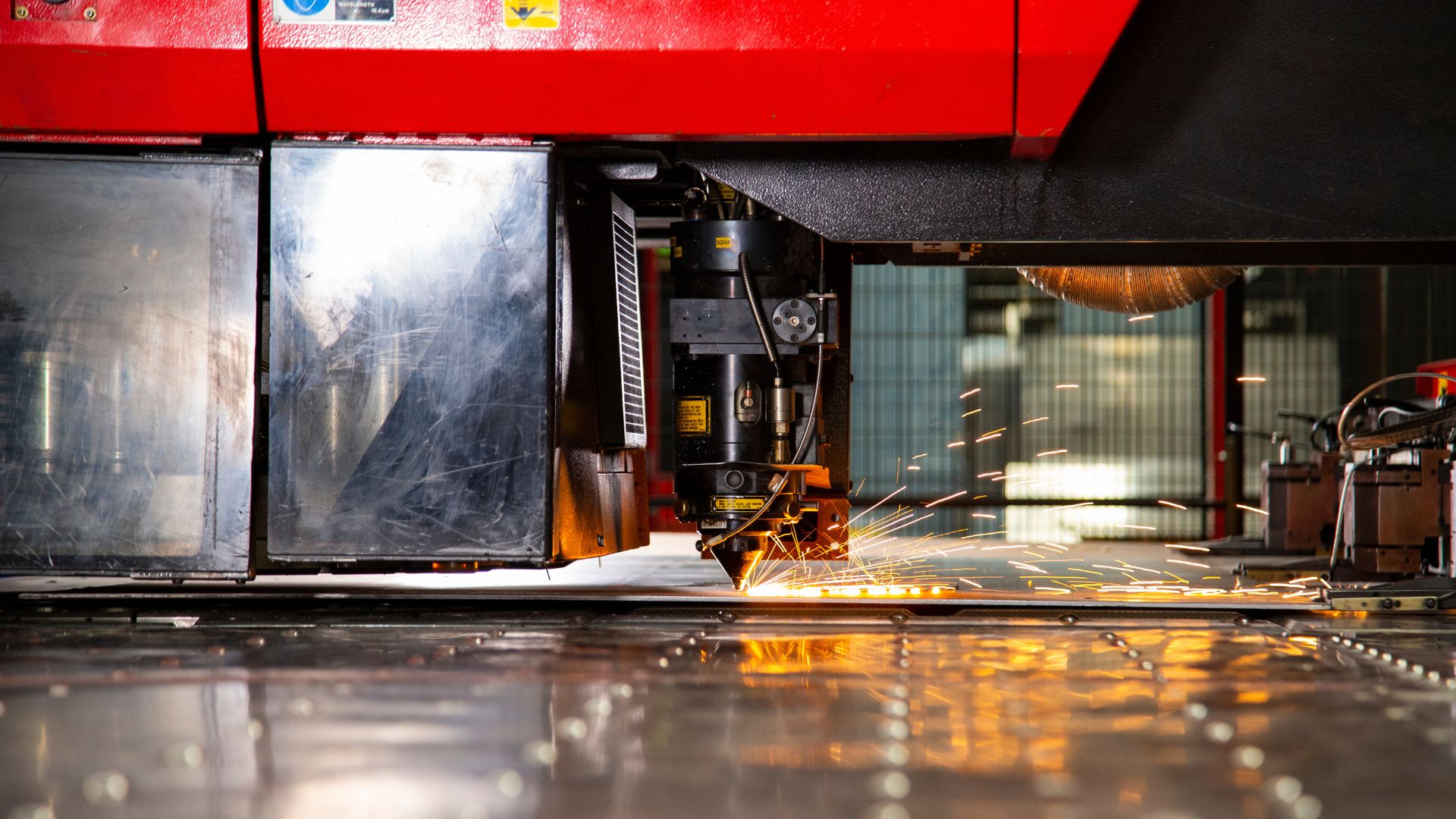

At Greengate Metal Components, we use advanced CNC laser cutting technology to produce precise and efficient metal components for the kiosk and vending machine industry.

Our laser cutting ensures every piece is accurately cut, enabling us to create detailed shapes and designs from materials like steel, aluminium, and stainless steel. This level of precision guarantees top-quality results for your machine enclosures, panels, and other vital components, ensuring reliability and durability in every product.

End to End Metal Manufacturing Solution

At Greengate Metal, we handle the entire manufacturing process for kiosks, ensuring precision, durability, and a seamless finish. Our end-to-end service eliminates the need for multiple suppliers, streamlining production and delivering high-quality kiosks built to your exact specifications.

Interested in Sheet Metal Fabrication for Kiosks and Vending Machines?

Contact us today to discuss your requirements and find out how we can help.

Contact Us

We Have The Expertise and Experience To Help

At Greengate Metal Components, we bring over 75 years of experience in sheet metal fabrication to support the manufacturing of kiosks and vending machines to produce high-quality, durable components.

Our team works closely with you during the design and engineering phases, offering valuable insights to optimise component performance, reduce production costs, and improve manufacturability, ensuring your military systems are built to the highest standards.

Our Machinery

CNC Laser Cutting Machine

The VENTIS-AJ is a groundbreaking sheet metal cutting machine featuring next-generation fibre laser technology. Its revolutionary beam-shaping system ensures precise laser beam control. Powered by AMADA’s high-quality single diode module fibre laser engines, it comes in 4 kW and 6 kW versions. Despite lower power requirements, the 4 kW model performs like 6-8 kW machines, and the 6 kW model matches 8-10 kW machines, delivering exceptional cutting quality.

AMADA HFE3i

The AMADA HFE3i series represents the latest advancement in hydraulic press brakes. Building on the solid HFE foundation, it introduces productivity enhancements and a cutting-edge multi-touch screen interface. With high precision, it delivers top-quality batches, low energy costs, and exceptional process stability. It offers tailored bending solutions to meet specific needs, available in a wide range of sizes (50 tons, 1.2 m to 400 tons, 6 m) and customisable options.

AMADA EMX-3610

The EM-MII range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing. The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

Frequently Asked Questions

Common materials used in kiosk and vending machine manufacturing include steel, aluminium, and stainless steel. Steel is widely chosen for its strength and durability, while aluminium is lighter, resistant to corrosion, and ideal for outdoor applications. Stainless steel is highly durable and resistant to rust, making it perfect for high-traffic environments. The choice of material depends on factors such as location, climate, design requirements, and the need for protection against wear and tear.

Sheet metal fabrication is crucial to the vending machine industry, as it allows for the creation of durable, custom components. This process ensures precise cuts, bends, and shapes, making it ideal for manufacturing strong, functional enclosures and structural parts for vending machines. Sheet metal can withstand heavy use, outdoor conditions, and vandalism, all of which are common in public-facing machines.

Outsourcing sheet metal fabrication allows companies in the vending machine industry to access specialised skills and advanced technology, such as CNC laser cutting, without investing in expensive equipment. It also reduces operational costs, as you won’t have to manage production in-house or deal with the complexities of sourcing materials. By working with experts like Greengate Metal Components, you gain access to efficient production processes, shorter lead times, and high-quality results. This lets you focus on other critical aspects of your business while ensuring your vending machines are built to last and perform reliably in the field.

At Greengate Metal Components, quality is a top priority. We use advanced CNC laser cutting technology to achieve precise and efficient metal component fabrication. Our machines are programmed for accuracy, ensuring consistent results across all orders. We work with a variety of materials, including steel, aluminium, and stainless steel, and each piece undergoes quality control checks throughout the manufacturing process.

Additionally, our experienced team ensures that every part meets the specific requirements of your kiosk or vending machine, from design to final delivery. This commitment ensures that our components are durable, reliable, and built to stand the test of time.

Yes, Greengate Metal Components can handle custom designs for kiosks and vending machines. We specialise in producing bespoke components to your exact specifications. Whether you require unique enclosures, brackets, or intricate parts, our advanced CNC machinery allows for detailed customisation, from shaping to precise cuts. Our team works closely with you to ensure that each component meets your functional and aesthetic requirements, providing solutions that align with your branding and operational needs.

The time it takes to fabricate parts for a vending machine depends on the complexity of the design and the volume of parts required. Simple components can typically be produced in a matter of days, while more intricate or custom parts may take longer. At Greengate Metal Components, we work to optimise production timelines without compromising on quality. We offer fast turnaround times for both standard and custom orders, ensuring that your vending machine parts are ready for assembly or installation on time.