EV Charging Point Sheet Metal Fabrication

What Is EV Charging Point Sheet Metal Fabrication?

As more electric vehicles (EVs) appear on roads, demand for dependable, efficient charging points keeps rising. To keep pace with this growth, organisations in both the public and private sectors are investing heavily in expanding charging infrastructure.

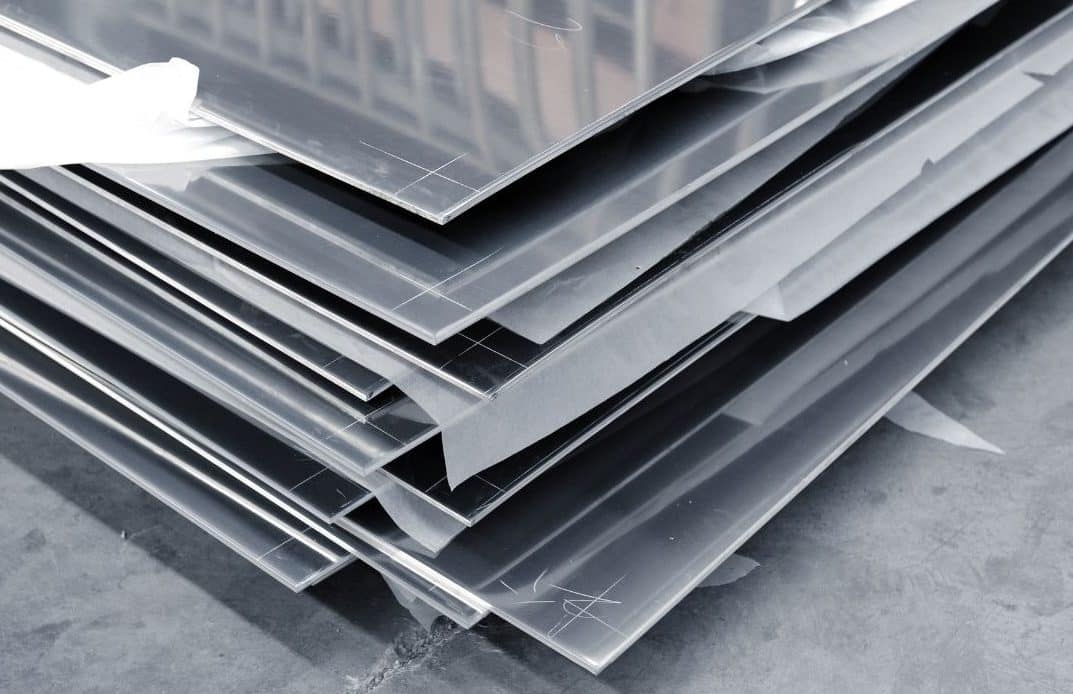

Sheet metal fabrication underpins the design and construction of EV charging enclosures, pillars and support structures, helping protect components, improve durability and deliver a professional finish for every installation.

Contact Us

Outsource EV Sheet Metal Fabricating

Outsourcing the fabrication of EV charging components lets you supply high-quality products without needing to run your own production facilities. By partnering with a specialist, you gain access to proven processes, skilled teams and established capacity.

Working with experienced fabricators helps shorten lead times and supports accurate, consistent results. In a market that is changing quickly, having a reliable partner makes it easier to keep up with demand and deliver charging solutions that support cleaner, more sustainable transport.

Our Services

Greengate Metal Components offers a full range of sheet metal services to support EV charging point projects, from initial design through to finished assemblies.

Sheet Metal Fabrication

Stainless Steel Fabrication

Aluminium Fabrication

Copper Fabrication

Mild Steel Fabrication

CNC Metal Laser Cutting

CNC Metal Punching

Sheet Metal Assembly

- Sheet Metal Design and Prototyping Services

- CNC Sheet Metal Punching Services

- Metal Sheet Laser Cutting Services

- Sheet Metal Bending Services

- Sheet Metal Spot Welding Services

- Metal Powder Coating Services

- Sheet Metal Product Assembly Services

- Sheet Metal Fabrication Services

Benefits of Outsourcing EV Component Fabricating

- Cost savings

- Access to expertise

- Scalability and flexibility

- Faster time-to-market

- Focus on core business activities

EV Charging Point Components We Can Manufacture

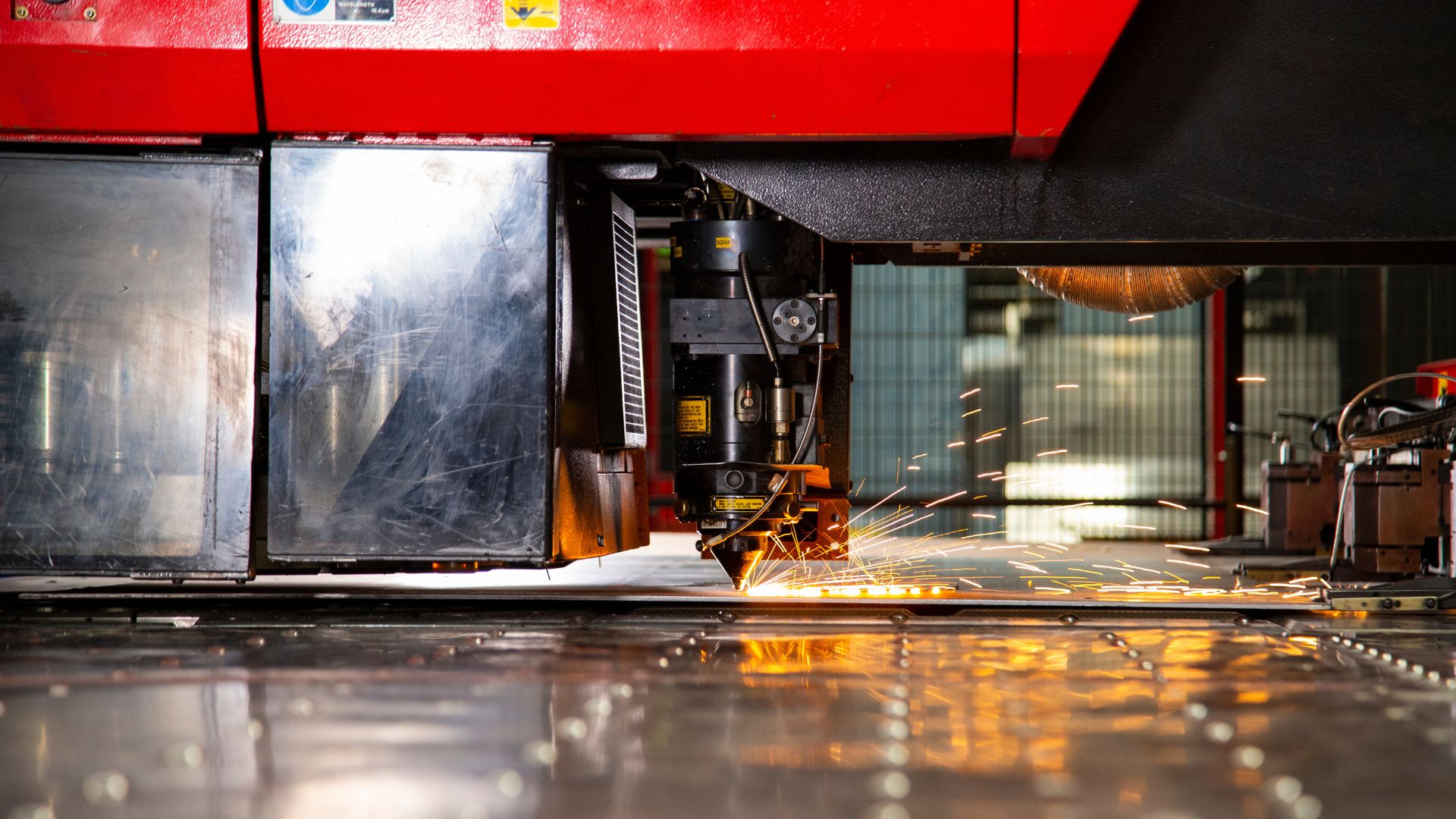

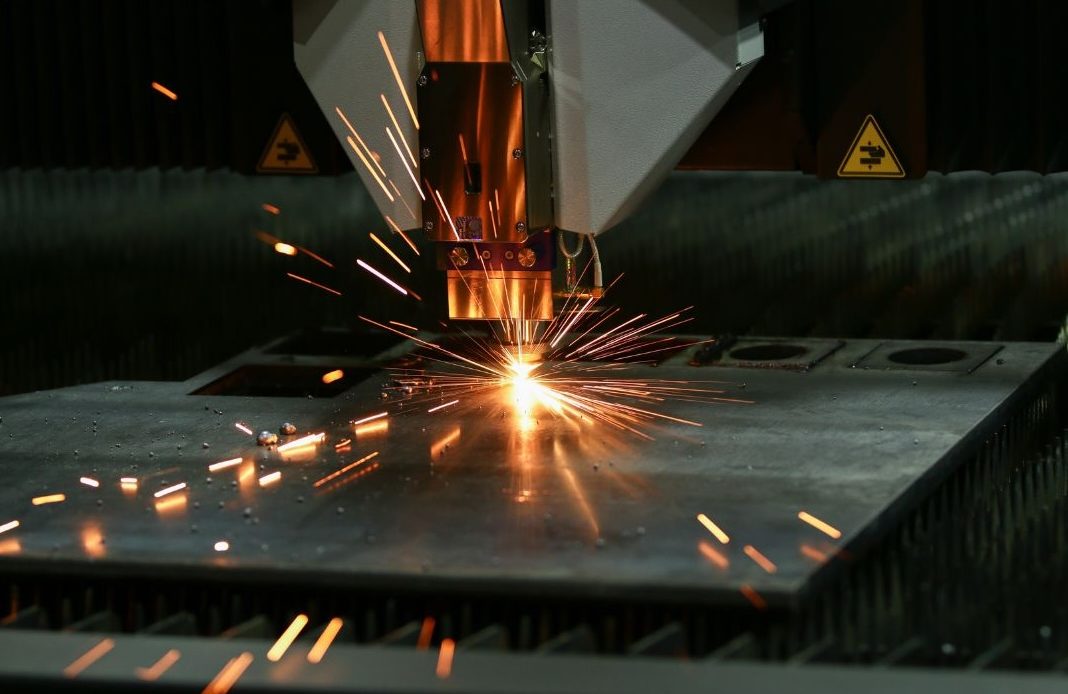

State of the Art Cutting Machinery

At Greengate Metal Components, CNC laser cutting technology is used to produce EV charging parts with a high level of accuracy and consistency.

This equipment allows intricate profiles to be cut from a wide range of materials, including steel, aluminium and stainless steel, helping deliver reliable, high-quality components for EV charging installations.

Interested in EV Charging Station Sheet Metal Fabrication?

Contact us today to discuss your requirements and find out how we can help.

Contact Us

We Have The Experience and Knowledge To Help

Greengate Metal Components draws on decades of fabrication experience to support EV manufacturers and infrastructure providers with dependable metalwork for charging equipment. With over 75 years in sheet metal, the team understands the demands placed on components used in this fast-growing sector.

Engineers work closely with customers through design and development, helping refine parts for performance, manufacturability and cost control so that EV charging systems are as durable and efficient as possible.

Our Machinery

CNC Laser Cutting Machine

The VENTIS-AJ uses next-generation fibre laser technology with advanced beam control to deliver accurate cutting performance. Available in 4 kW and 6 kW versions, it achieves results comparable with higher power equipment while keeping energy use under control.

AMADA HFE3i

The HFE3i press brake builds on AMADA’s established HFE range and introduces a modern multi-touch interface and productivity upgrades. It provides precise bending, stable processing and low running costs across a wide selection of sizes and configurations.

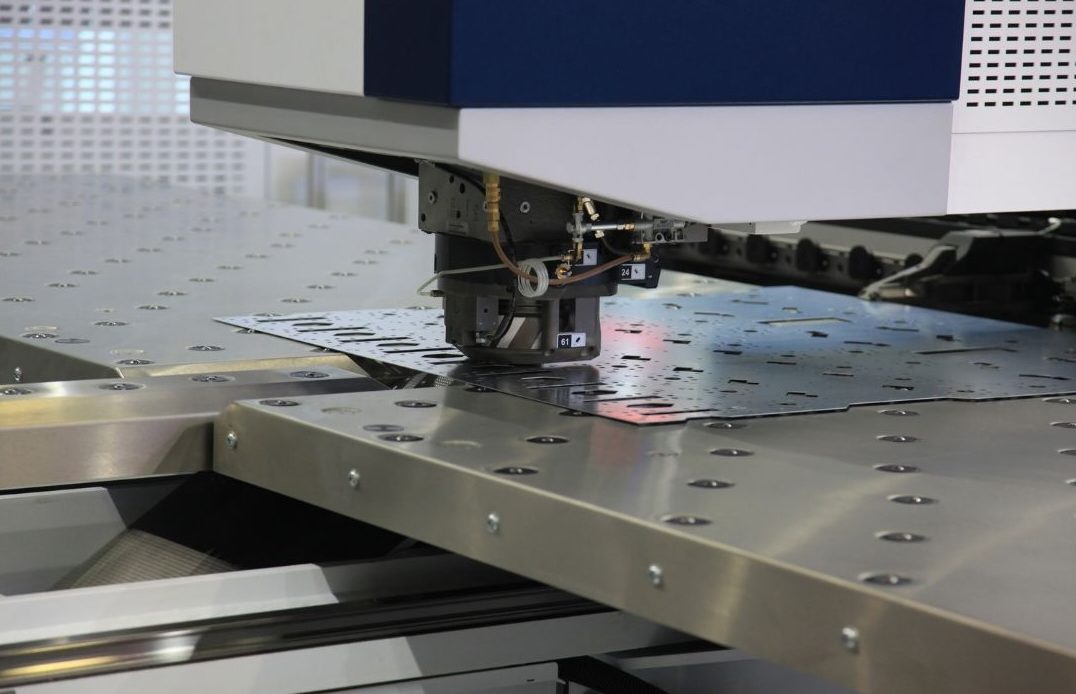

AMADA EMX-3610

The EM-MII punching range features a 30 ton dual servo electric motor system and AMADA’s advanced turret design. Optional tool identification and dedicated tapping units help reduce setup time and support efficient, high-quality punching operations.

Frequently Asked Questions

An EV charging point, or electric vehicle charging station, is equipment that supplies electricity to recharge an EV battery. It serves a similar purpose to a fuel pump for conventionally powered vehicles, but delivers electrical energy instead of liquid fuel.

Charging points range from slower domestic units through to rapid and ultra-rapid public chargers, and connect to the vehicle via a cable and plug. They are a key part of the move toward cleaner, low-emission transport.

We provide full sheet metal fabrication support for EV charging projects, including precision cutting, forming, welding and assembly. Components are produced to match your designs and performance requirements, whether you need one-off prototypes or ongoing production runs.

Yes. Custom metalwork is a core part of our service. We work to your drawings and specifications, including dimensions, features and finishing needs, so that enclosures and other parts fit precisely and meet project and safety expectations.

Our facilities are set up for both smaller batches and high-volume production. Whether you are trialling a new design or rolling out a full network of charging points, we focus on consistent quality and reliable delivery schedules.

Yes. Our team can support you with design input to help make components easier to manufacture, reduce waste and improve performance. We work alongside your engineers so that parts are ready for production and meet the technical brief.

With more than 75 years in sheet metal fabrication, modern machinery and a strong focus on accuracy, Greengate Metal Components delivers EV charging parts that are built for long-term use. Dedicated support and dependable processes help set our service apart.