Stainless Steel Sheet Metal Fabricators

Our Stainless Steel Fabrication Services

Greengate Metal Components brings together all the vital fabrication processes for stainless steel, under one roof. Each project is executed with precision and care, ensuring you receive components that meet your exact specifications, whatever the deadline.

Our extensive skills in working with this versatile alloy includes precise laser cutting, welding, spot welding, bending, forming and detailed finishing. We also offer full-scale product assembly, advanced CNC metal punching and innovative design and prototyping services.

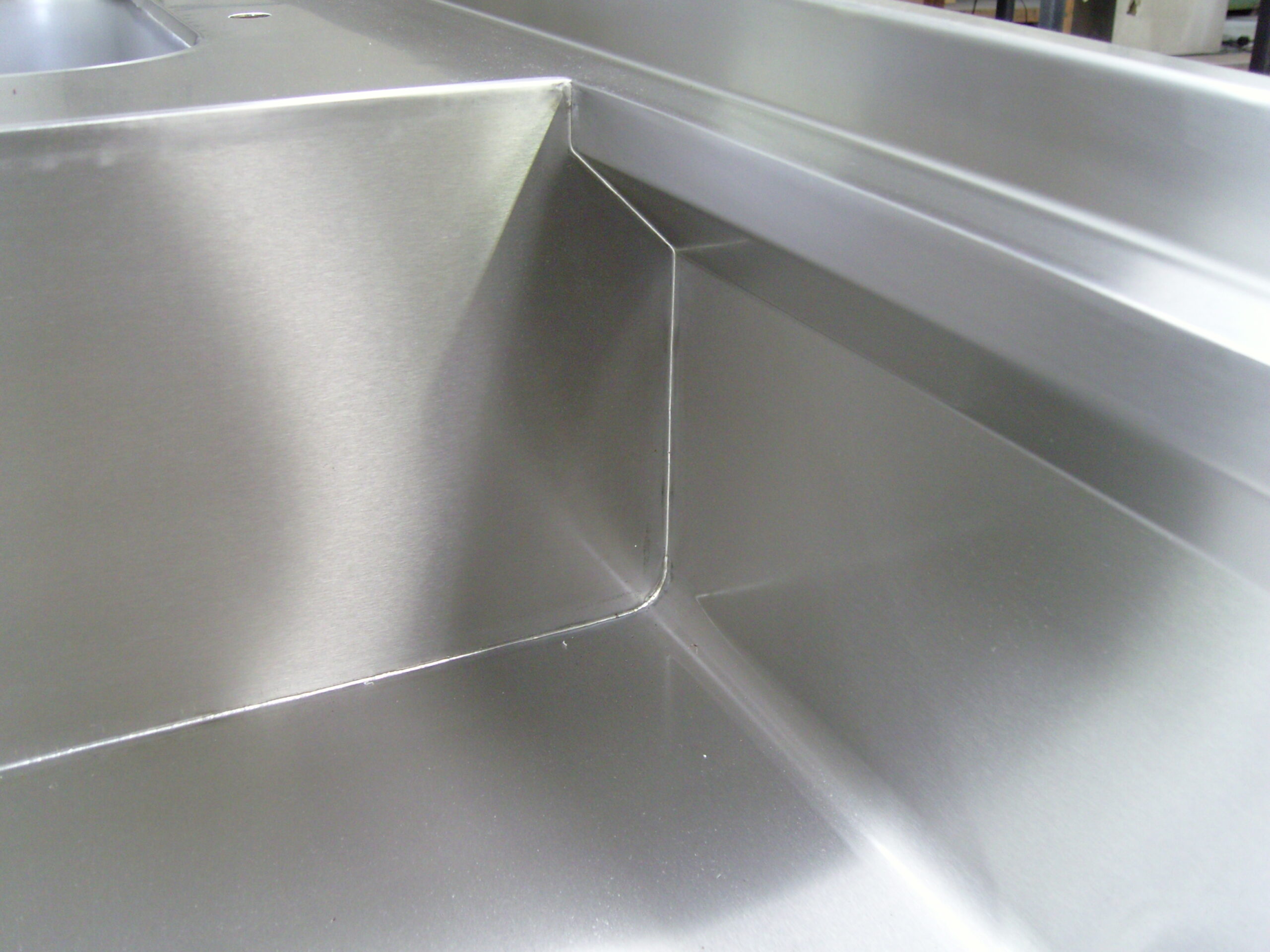

Stainless steel is a staple of the pharmaceutical and healthcare sectors, with everything from bio storage, laboratory furniture to precision medical tools being made from it. It’s also widely used in food preparation and hospitality, providing the perfect material for worktops, food storage and cooking equipment. In both cases, the benefit is its resistance to corrosion and an ability to be boiled, steamed and chemically cleaned to give spotless, hygienic and sterile equipment to work with.

The fabrication techniques also play a part in those properties. Products need to be smooth, devoid of cracks, grooves, poor joints and sharp corners, as that is where contaminants and microbes can hide. Our experience and understanding of these sectors ensures your products will be perfectly suited to their intended uses.

Contact UsWhy Choose Greengate Metal Components?

Greengate stands out through our history, our technical excellence and our unwavering commitment to quality. We are seasoned professionals who bring decades of industry experience and a sharp eye for detail to every project we undertake.

We don’t see ourselves as merely offering bespoke steel fabrication services; we regard ourselves as partners in your project’s success. From the initial design stage through to production and final assembly, we work closely with our clients to ensure a thorough understanding of their specific requirements. That’s how we can deliver solutions that exceed expectations.

At the core of our operations is rigorous quality control. Our ISO certifications prove that we can and will always meet the highest industry standards. Also, our continual investment in the latest technological advancements ensures we stay at the cutting edge of the industry, offering precision and innovation in every component we produce.

We are constantly striving to capitalise on new ways of working with metals to offer strength, efficiency and fitness for purpose.

Contact UsOur Capabilities

Fabrication Services We Offer

- Laser Cutting

- Powder Coating

- Finishing

- Welding and Spot Welding

- Bending and Forming

- Product Assembly

- Design and Prototyping

- CNC Metal Punching

Metal Thickness

- Mild Steel: 0.5mm-25mm

- Stainless Steel: 0.5mm-20mm

- Aluminium: 0.5mm-16mm

- Brass: 0.5mm-10mm

- Copper: 0.5mm-8mm

Sheet Sizes

Up to 3000 x 1500mm

Stainless Steel Sheet Fabrication Processes

Our state-of-the-art facilities and highly experienced team excel in all facets of stainless steel sheet fabrication, ensuring exceptional results. For stainless steel of between 0.5mm and 20mm in thickness, we can perform the following processes:

- Laser cutting: Achieve accurate cuts with minimal waste, ensuring optimal cost-efficiency.

- Powder coating: Even stainless steel can benefit from powder coating in some applications. We provide attractive powder coating for added durability and aesthetic value.

- Finishing: Our attention to detail in finishing ensures end products that meet your brief.

- Welding: Our skilled MIG, TIG and spot welders deliver strong, reliable joints, critical for the integrity of your components.

- Bending and forming: We specialise in crafting complex shapes with precise bending and forming techniques.

- Product assembly: Our assembly solutions streamline production, bringing you integration and high-quality final products.

- Design and prototyping: Greengate’s innovative design and prototyping services bring your concepts to life. Now you can test and analyse their performance before a full production run.

- CNC metal punching: Achieve precision punching for intricate designs using the latest CNC metal punching equipment.

Our Machinery

Ventis-AJ Fibre Laser

The VENTIS-AJ is the biggest innovation in sheet metal cutting and introduces the next generation of fibre laser processing machines. What makes this technology truly revolutionary is the innovative beam shaping system that allows for precise control of the laser beam motion. Utilizing AMADA’s high power, single diode module fibre laser engines, the VENTIS is available as 4 kW or 6 kW. These engines provide a very high quality laser beam, allowing the 4 kW VENTIS-AJ to perform similar to 6-8 kW machines, and the 6 kW VENTIS-AJ to perform similar to 8-10kW machines, with much less power requirements and an unrivalled cutting quality.

AMADA HFE3i

The AMADA HFE3i series are the latest evolution in hydraulic drive press brakes. Designed with the solid characteristics of the HFE series, the 3i series features new additions to improve productivity, as well as, a highly innovative multi-touch screen interface. The processing precision enables the production of very high quality batches, at low energy costs and with an unrivalled process stability. The extensive range of sizes (from 50 tons, 1.2 m to 400 tons, 6 m) and options mean that customers can configure the ideal bending solution for their specific needs.

AMADA EMX-3610

The EM-MII range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing. The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

More About Greengate Metal Components

Greengate Metal Components offers excellence in stainless steel custom fabrication. Our state-of-the-art facilities are equipped to handle projects of any size, offering the flexibility and scalability to meet diverse client needs seamlessly.

Every client has unique requirements, and we offer bespoke stainless steel solutions tailored to meet those specific needs. This adaptability, coupled with our quality assurance processes, ensures that every component produced adheres to the desired standards of quality and durability.

Our commitment to sustainable practices underscores our dedication to environmental stewardship. Whatever stainless steel service we perform, we prioritise traceability and waste minimisation to ensure our operations have as little environmental impact as possible. As customers become increasingly savvy about the origins and impact of the products they purchase, it’s reassuring to know that every link in your supply chain with Greengate is dependable and responsible.

Having Greengate as your bespoke stainless steel fabrication partner grants you access to industry-leading expertise, cutting-edge technology and a guarantee of excellence. That’s how we can assure you that your projects are executed to the highest standards. Talk to us about your proposals for anything stainless steel related – we could be the partner you’re looking for.

Our Services

CNC Metal Laser Cutting

At Greengate Metal Components, our CNC metal laser cutting services offer exceptional precision, speed, and efficiency for a wide variety of fabrication needs. Using advanced laser technology, we can cut complex shapes and fine details with minimal waste and high repeatability.

Our skilled team ensures consistent quality and fast turnaround times, whether for prototypes or large-scale production. We work with various metals and thicknesses, delivering reliable results that meet the exact specifications of each project.

CNC Metal Punching

At Greengate Metal Components, our CNC metal punching services offer fast, accurate, and cost-effective solutions for producing complex metal parts.

Using advanced CNC punching machines, we can handle a wide range of materials and thicknesses with exceptional precision. This technology enables high-speed production with minimal waste, making it ideal for both small and large batch runs.

Sheet Metal Assembly

Our sheet metal assembly services are designed to deliver fully integrated, ready-to-use components that meet exact specifications.

We combine expert fabrication with skilled assembly techniques, including welding, fastening, and finishing, to ensure each product is precise and reliable. Our team works closely with clients to streamline production, reduce lead times, and maintain the highest quality standards.

Metal Welding

We offer professional metal welding services as part of our fabrication capabilities. Our skilled welders use advanced techniques and equipment to ensure strong, precise, and clean welds across a variety of metals.

Whether for structural frameworks or detailed component assembly, we maintain high standards of quality and consistency. With a focus on durability and accuracy, our welding services support both small and large-scale projects, tailored to meet the specific requirements of each client.

Metal Bending & Forming

At Greengate Metal Components, our metal bending and forming services combine precision, efficiency, and versatility to meet a wide range of project requirements. Using advanced CNC press brakes and skilled technicians, we can accurately shape sheet metal into complex forms with tight tolerances.

Our expertise in metal forming allows us to support custom designs, helping clients achieve optimal functionality and performance.

Metal Design & Prototyping

At Greengate Metal Components, our metal design and prototyping services ensure your ideas are brought to life with precision and efficiency. Using advanced CAD software and engineering expertise, we work closely with clients to develop accurate prototypes that meet functional and aesthetic requirements.

This process allows for thorough testing, refinement, and validation before full-scale production, reducing risk and saving time.

Metal Powder Coating

We offer professional metal powder coating services designed to enhance durability, appearance, and corrosion resistance.

Our advanced powder coating process delivers a smooth, uniform finish that adheres exceptionally well to metal surfaces, ensuring long-lasting performance. Available in a wide range of colours and textures, our coatings are ideal for both functional and aesthetic applications.