CNC & Sheet Metal Punching

Our CNC Metal Punching Services

Greengate Metal Components is experienced in punching metal components from various materials including: mild steel, stainless steel, aluminium, zintec, copper and brass. Our investment in the latest metal punching technology and machinery, alongside our wealth of expertise, ensures that Greengate Metal Components can create complex components more efficiently and at a higher quality than the competition.

This offer of efficiency, quality and value for money is assured by our highly experienced team and the proficient use of AMADA CNC punching machines.

Computer Numerically Controlled (CNC) punching plays an important role in sheet metal fabrication and manufacturing. CNC punch presses can deliver a potentially quicker and more economical component, depending on its intricacy and purpose. Simple profiles and large volumes are ideally suited to punching.

The ability to produce components at a high speed and with a high accuracy (±0.125mm) enables Greengate Metal Components to offer high-quality components at a competitive price.

Contact UsWhat Is CNC Metal Punching?

At Greengate Metal Components, CNC metal punching is where speed, strength and precision come together. From prototypes to full production runs, our advanced punching equipment delivers clean, accurate results every time, even on complex layouts.

Design engineers and SMEs rely on us for fast turnaround, consistent quality and tight tolerances. We offer quick setup times, flexible tooling and careful handling of materials ranging from mild steel to aluminium.

Contact UsBenefits of Choosing CNC Metal Punching

Precision and Consistency

Fast Turnaround Times

Scalability

Cost Efficient

Bespoke CNC Metal Punching Services

At Greengate Metal Components, bespoke CNC metal punching combines precision, speed and flexibility to produce custom metal parts. Using advanced punching equipment, we work to exact specifications to create tailored holes, forms and patterns in materials such as mild steel, stainless steel and aluminium.

This service supports industries that require accuracy and reliability, including aerospace, defence and medical. Our team delivers unique designs, tight tolerances and short lead times, with consistent quality throughout every batch. With efficient setup and flexible tooling, CNC punching is a cost-effective way to produce detailed components at scale. Bespoke solutions from Greengate ensure each part is made to fit the exact needs of your project.

Contact UsWhy Choose Greengate Metal Components?

The AMADA punch press machines are capable of producing a large variety of shapes, from simple circles or rectangles to overlapping geometrical 3D designs that can allow for increased flexibility in the fabrication of punched sheet metal components.

Greengate Metal Components integrates CAD and RADAN software with the CNC machinery, calculating the most efficient process and component nesting. This allows GMC to have maximum material utilisation, minimises material wastage and provides a quicker turnaround of punched sheet metal products.

CNC-controlled punch and laser combination machines are capable of even more, allowing for both processes without the need for extra tool changes or increased set up costs. The AMADA metal punch machines can also perform simple metal forming and tapping operations to be carried out during the same cycle.

Contact Us

Our Sheet Metal Punching Capabilities

Punching Services We Offer

- CNC Punching

- CNC Punch and Laser Combination

Metal Thickness

- Mild Steel: 0.5-3mm

- Stainless Steel: 0.503mm

- Aluminium: 0.5-3mm

- Brass: 0.5-3mm

- Copper: 0.5-3mm

- Zintec/Galvanised Steel: 0.5-3mm

- Coated Sheets: 0.5-3mm

Sheet Sizes

Up to 3,000 x 1,500mm

Our Expert CNC Metal Punching Machinery

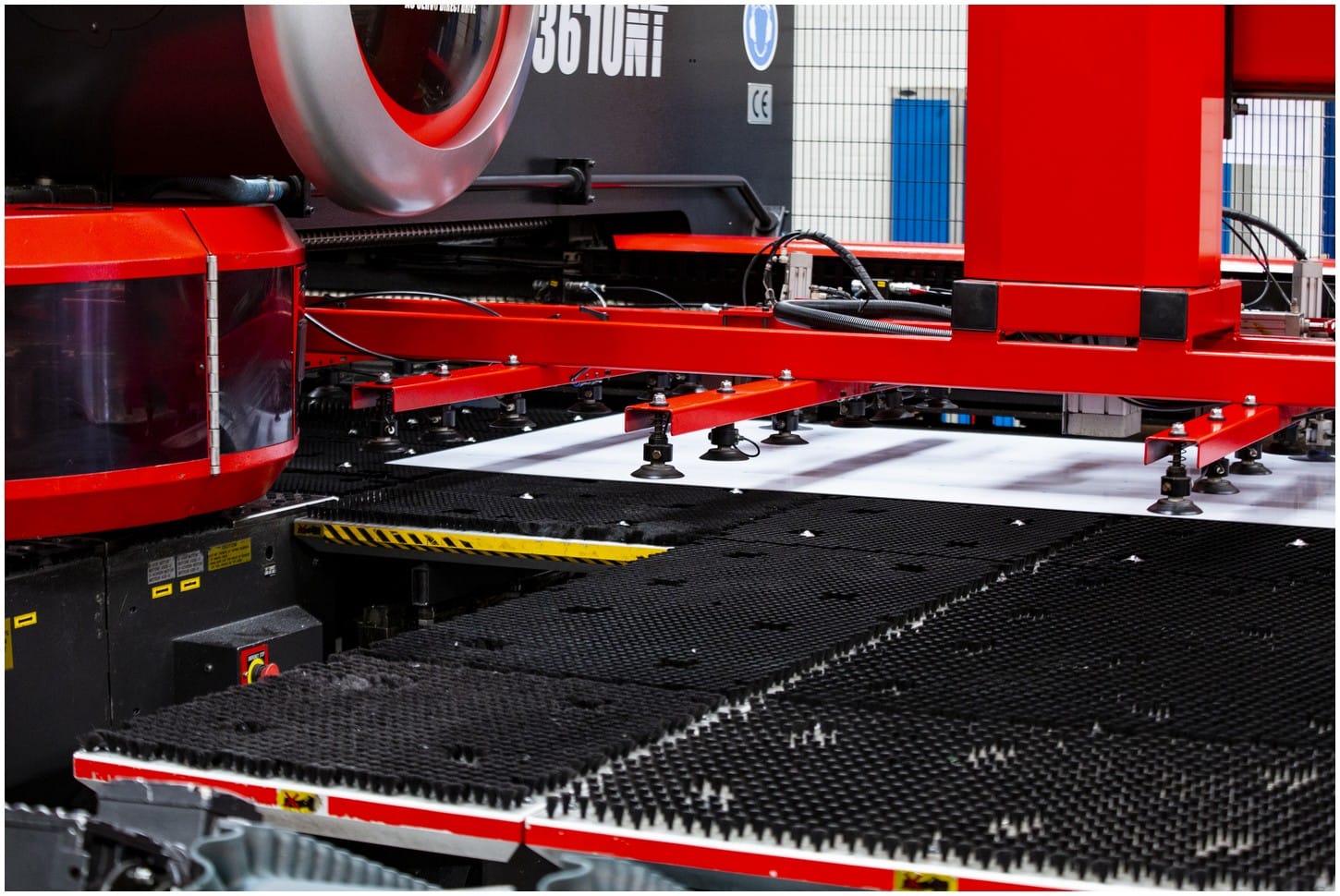

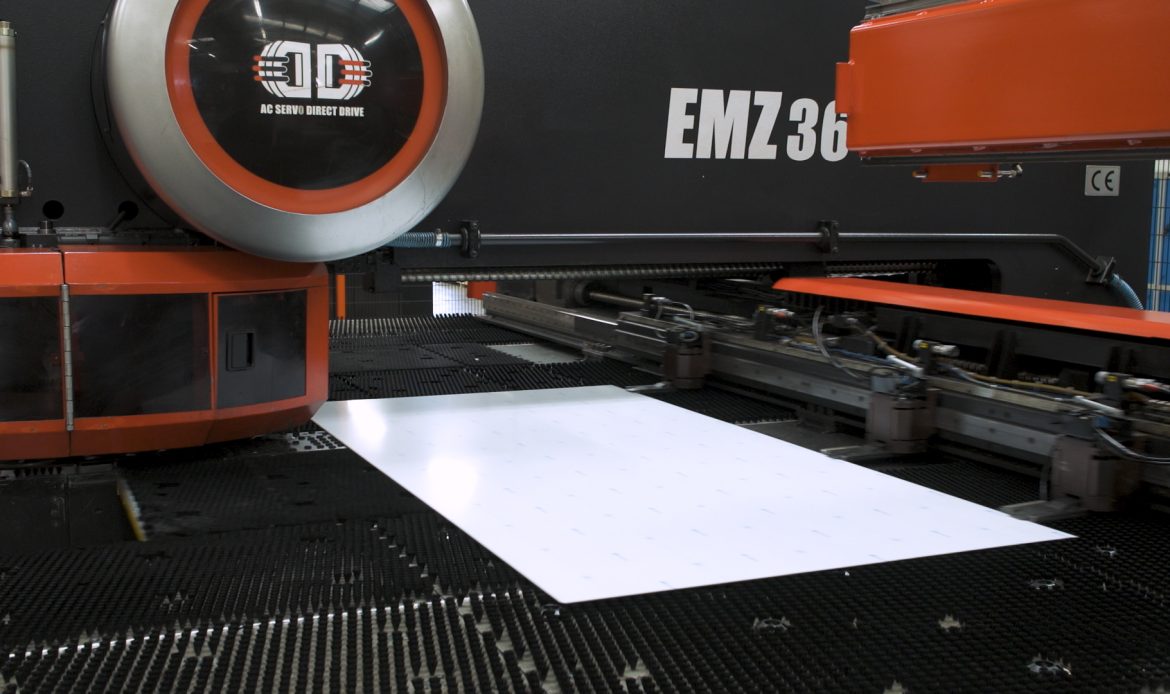

AMADA EMZ-3610

The Amada EMZ-3610 is a fast, versatile CNC turret punch press built for precision and efficiency in sheet metal work. With a 30-ton punching force and a 58-station turret, it handles a wide variety of shapes and forms without constant tooling changes, making it ideal for both complex jobs and high-volume runs.

One of its standout features is the brush table and automatic sheet repositioning system, which helps protect surface finishes and maintain accuracy across larger sheets. It’s designed to reduce material handling, speed up production and deliver repeatable, high-quality results.

The EMZ-3610 is especially effective when consistent accuracy and fast turnaround are essential. It’s capable of punching intricate patterns, louvres, forms and perforations in materials like mild steel, aluminium and stainless steel.

Contact Us

Interested in our CNC Metal Punching Services? Contact us today with your specific requirements to find out how Greengate Metal Components can help.

Contact UsSectors We Can Provide CNC Metal Punching Services For

Greengate Metal Components offers dependable, high-quality CNC metal punching services, tailored to meet the varied requirements of a wide range of businesses, including:

Contact UsAerospace

Architecture

Pharmacy and Medical

Kiosk and Vending

Metal Cabinets

Mining

Automotive Chargers

Defence

Our Latest Blogs

CNC Metal Punching Sector Applications

CNC Metal Punching for Aerospace

At Greengate Metal Components, our CNC metal punching services provide fast, precise, and cost-effective solutions tailored to the demanding standards of the aerospace industry.

Using advanced CNC punching machines, we work with a variety of aerospace-grade materials and thicknesses, delivering components that meet strict tolerances and quality requirements. This technology allows high-speed production while minimising waste, making it ideal for both prototype development and large-scale manufacturing runs.

CNC Metal Punching for Defence and Military

Our sheet metal assembly services incorporate precision CNC metal punching to create fully integrated, ready-to-use components that meet exact specifications.

By combining expert punching with skilled assembly techniques such as welding, fastening and finishing, we ensure every product is accurate and reliable. We work closely with clients in the military and defence sectors to optimise production processes, reduce lead times and uphold the highest quality standards.

CNC Metal Punching for the Pharmaceutical and Medical Sector

At Greengate Medical Components, our CNC punching services provide precise, efficient, and cost-effective solutions tailored to meet the exacting standards of the pharmaceutical and medical device industries.

Employing state-of-the-art CNC punching technology, we process a broad range of medical-grade materials and thicknesses, producing components that conform to stringent quality requirements and tight tolerances. This advanced method supports both rapid prototyping and high-volume manufacturing, ensuring minimal material wastage and exceptional consistency.

CNC Metal Punching for Kiosk and Vending Machines

We use precise CNC punching as part of our sheet metal fabrication to create components that are ready to be assembled and installed straight away.

By combining skilled punching with careful assembly methods like welding, fastening and finishing, we make sure every product is reliable and built to last. We work closely with companies in the kiosk and vending machine industry to improve production, speed up lead times and maintain excellent quality throughout.

CNC Metal Punching for Metal Cabinets and Enclosures

At Greengate Fabrications, our CNC punching services offer accurate, efficient, and cost-effective solutions designed to meet the demanding requirements of metal cabinet and enclosure manufacturing.

Using the latest CNC punching equipment, we work with a wide range of metals and thicknesses to produce components that meet strict quality standards and precise measurements. Our process is ideal for both quick prototyping and large-scale production, helping to reduce material waste while delivering consistent, high-quality results.

CNC Metal Punching for Mining and Material Extraction

We use precise CNC punching as part of our sheet metal fabrication to create rugged, heavy-duty components designed specifically for mining and material extraction equipment.

Combining expert punching with durable assembly methods such as welding, fastening and finishing, we make sure every part can withstand harsh environments and continuous heavy use. We partner closely with mining companies and equipment manufacturers to streamline production, reduce lead times and ensure all components meet strict industry standards.

CNC Metal Punching for EV Chargers

At Greengate Fabrications, our CNC punching services are tailored to the specialist demands of electric vehicle (EV) charger enclosure manufacturing.

We work with industry-standard materials such as galvanised and powder-coated steel, aluminium, and stainless steel to produce durable, weather-resistant housings suitable for both public and private EV charging points. Our advanced CNC punching technology allows us to create precise cut-outs for screens, vents, cable access, and mounting features, ensuring every part fits perfectly during final assembly.

CNC Metal Punching for Architectural Metal Work

We use precision CNC punching in our sheet metal work to produce strong, reliable components for architectural metalwork projects.

Our team combines accurate punching with proven assembly techniques like welding, fastening and finishing, making sure every part is built to a high standard and ready to perform. Whether it’s for façades, balustrades or bespoke decorative features, we work closely with architects, designers and contractors to deliver high-quality results, meet tight deadlines and support smooth project delivery from start to finish.

Our Services

CNC Metal Laser Cutting

At Greengate Metal Components, our CNC metal laser cutting services offer exceptional precision, speed, and efficiency for a wide variety of fabrication needs. Using advanced laser technology, we can cut complex shapes and fine details with minimal waste and high repeatability.

Our skilled team ensures consistent quality and fast turnaround times, whether for prototypes or large-scale production. We work with various metals and thicknesses, delivering reliable results that meet the exact specifications of each project.

CNC Metal Punching

At Greengate Metal Components, our CNC metal punching services offer fast, accurate, and cost-effective solutions for producing complex metal parts.

Using advanced CNC punching machines, we can handle a wide range of materials and thicknesses with exceptional precision. This technology enables high-speed production with minimal waste, making it ideal for both small and large batch runs.

Sheet Metal Assembly

Our sheet metal assembly services are designed to deliver fully integrated, ready-to-use components that meet exact specifications.

We combine expert fabrication with skilled assembly techniques, including welding, fastening, and finishing, to ensure each product is precise and reliable. Our team works closely with clients to streamline production, reduce lead times, and maintain the highest quality standards.

Metal Welding

We offer professional metal welding services as part of our fabrication capabilities. Our skilled welders use advanced techniques and equipment to ensure strong, precise, and clean welds across a variety of metals.

Whether for structural frameworks or detailed component assembly, we maintain high standards of quality and consistency. With a focus on durability and accuracy, our welding services support both small and large-scale projects, tailored to meet the specific requirements of each client.

Metal Bending & Forming

At Greengate Metal Components, our metal bending and forming services combine precision, efficiency, and versatility to meet a wide range of project requirements. Using advanced CNC press brakes and skilled technicians, we can accurately shape sheet metal into complex forms with tight tolerances.

Our expertise in metal forming allows us to support custom designs, helping clients achieve optimal functionality and performance.

Metal Design & Prototyping

At Greengate Metal Components, our metal design and prototyping services ensure your ideas are brought to life with precision and efficiency. Using advanced CAD software and engineering expertise, we work closely with clients to develop accurate prototypes that meet functional and aesthetic requirements.

This process allows for thorough testing, refinement, and validation before full-scale production, reducing risk and saving time.

Metal Powder Coating

We offer professional metal powder coating services designed to enhance durability, appearance, and corrosion resistance.

Our advanced powder coating process delivers a smooth, uniform finish that adheres exceptionally well to metal surfaces, ensuring long-lasting performance. Available in a wide range of colours and textures, our coatings are ideal for both functional and aesthetic applications.