How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

Before any bending begins, a sheet metal part starts life as a 2D layout. That’s the flat pattern development. It’s the cut shape that tells machines where to fold, punch, or trim, all before the first tool touches metal. Getting this right early on reduces waste, avoids guesswork, and improves part accuracy.

At Greengate Meta Components, it’s how we keep fabrication process accuracy high, from 2D to 3D sheet metal, without the usual production delays.

A flat pattern isn’t just a technical drawing; it’s what turns design intent into a part that fits and functions. Without it, bending becomes guesswork, and guesswork leads to waste.

By planning each fold and cut, engineers keep production tight and predictable. In metal fabrication design, this saves time, cuts down rework, and avoids last-minute fixes on the shop floor.

It’s not just about precision either; smart sheet metal layout techniques help make the most of raw materials. So, whether it’s a prototype or a full batch, the flat pattern keeps everything aligned, efficient, and ready for production with fewer headaches.

Before forming begins, every part needs a plan, and that plan lives in the flat pattern. It’s not just a sketch. It considers how metal behaves when bent, stretched, or compressed.

This is where the bend allowance calculation comes in. Bends don’t just fold; they stretch the material. If you skip this step, the part might not line up correctly. The bend radius, material type, and thickness all change how much metal needs to be added or removed from the flat layout.

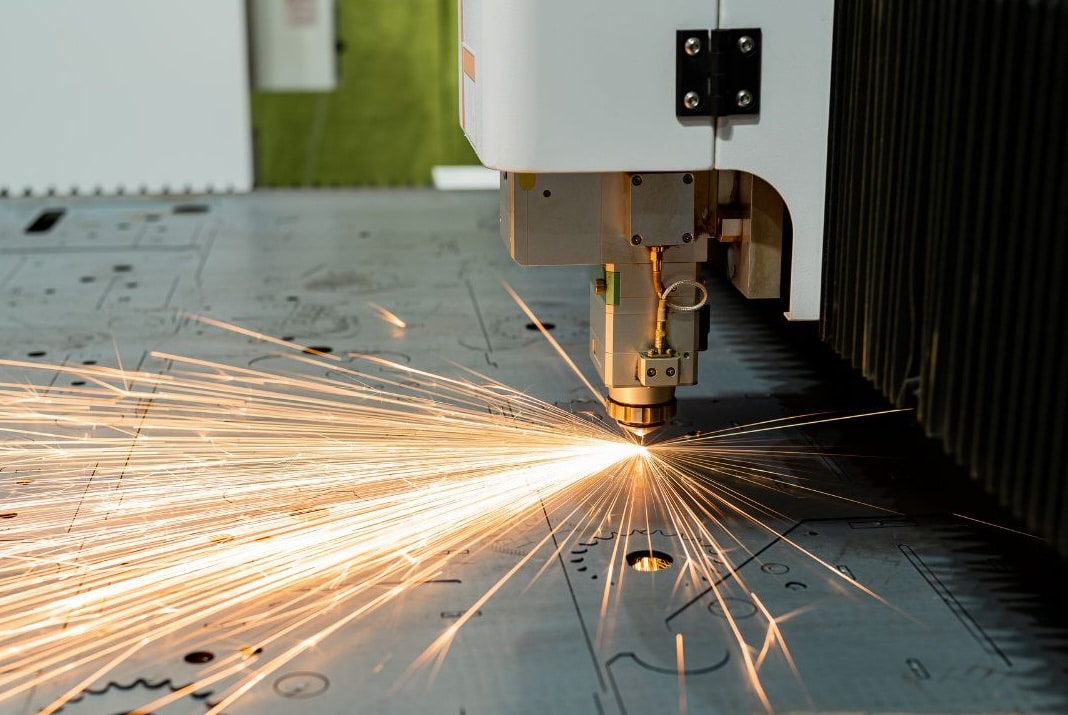

Designers usually rely on software to work all this out, using rules based on material behaviour and proven geometry. From there, the sheet metal flat pattern becomes the go-to reference for laser cutting, punching, or forming.

Think of it like this — you’re designing a control box. The flat pattern lays out each face as one piece, ready to fold into shape. That’s smart 2D to 3D sheet metal planning.

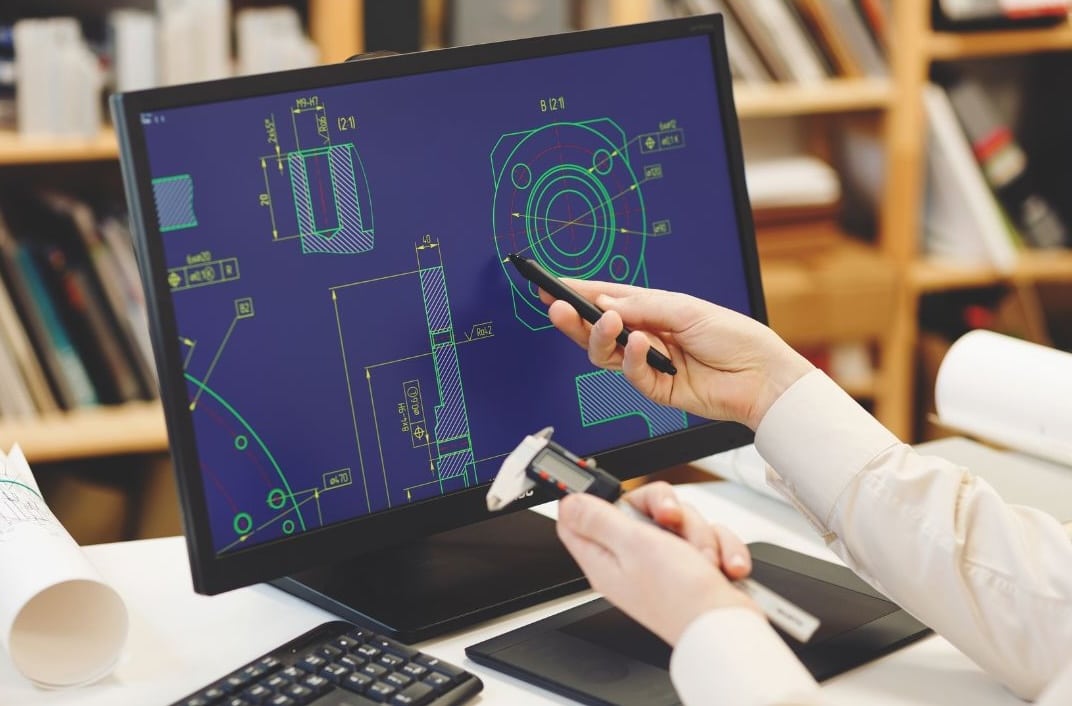

In most modern workshops, flat patterns aren’t drawn by hand. They’re created using specialist CAD sheet metal design tools that turn 3D models into exact 2D layouts — no trial and error, just geometry that works.

Software like SolidWorks, Autodesk Inventor, and Fusion 360 is seen as standard across the industry. These platforms automatically unfold 3D parts, apply bend allowance calculations, and prepare the files for CNC cutting or laser profiling. That saves a lot of time, especially on more complex assemblies.

Here at Greengate Metal Components, we don’t just use these tools; we rely on them. Our systems are tuned to deliver high-accuracy sheet metal flat patterns that align perfectly with manufacturing specs. That means less adjustment on the shop floor and far smoother transitions from design to part.

Depending on the setup and complexity, there are a few ways to create a flat pattern. Here’s a quick breakdown:

Each method plays its part, but in fast-paced environments, automation usually wins. It’s quicker, more consistent, and makes the fabrication process accuracy far easier to manage, especially when working with tight tolerances or repeatable parts.

Even with good software, flat patterning isn’t always straightforward. Bend allowance calculation is one of the main challenges — get it wrong, and the final part won’t match the design.

Then there’s the K-factor, which helps predict how the metal will stretch during forming. It’s tricky to get right, especially with different materials or thicknesses.

Other issues? Tolerances, grain direction, and relying on default CAD settings can all throw things off. A flat pattern that looks perfect on screen might not behave the same on the bench.

Over time, our team has learned to watch these details closely. It means fewer surprises during manufacture and more reliable results, whether it’s a one-off or a full production run.

Flat patterning isn’t just for one type of job; it’s everywhere. From small housings to full-scale industrial assemblies, this step is what keeps things moving with accuracy and consistency.

Take electrical enclosures, for instance. These often involve precise cut-outs, folds, and hinged panels, all planned from a sheet metal flat pattern. In HVAC, ducts and vents are laid out flat first, helping installers get the right fit without costly on-site adjustments. Structural parts? Same deal. Frames, brackets, and covers are usually designed with flat pattern workflows before fabrication begins.

At Greengate, we use metal fabrication design to support sectors like electronics, construction, and engineering. Whether it’s one prototype or a production batch, every piece starts as a flat pattern — shaped to match the spec, and built to hold up in use.

When the flat pattern’s right, just about everything else tends to fall into place. Here’s what that looks like in practice:

That combination of speed, consistency, and accuracy? It tends to make life easier for everyone involved, from design through to delivery.

Flat pattern development isn’t just a design step — it’s the point where digital intent meets real-world precision. Whether you’re tweaking a prototype or scaling up a full production run, accurate patterns lead to better parts, faster workflows, and fewer hiccups along the way.

If you’re looking for a partner who gets the technical side and can deliver on it too, our team here at Greengate Metal Components is ready. We combine advanced CAD expertise with practical, shop-floor know-how to turn 3D designs into production-ready metal parts, with accuracy built in from the start.

Need a part that fits right the first time? Let’s talk about your next sheet metal project.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...