How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

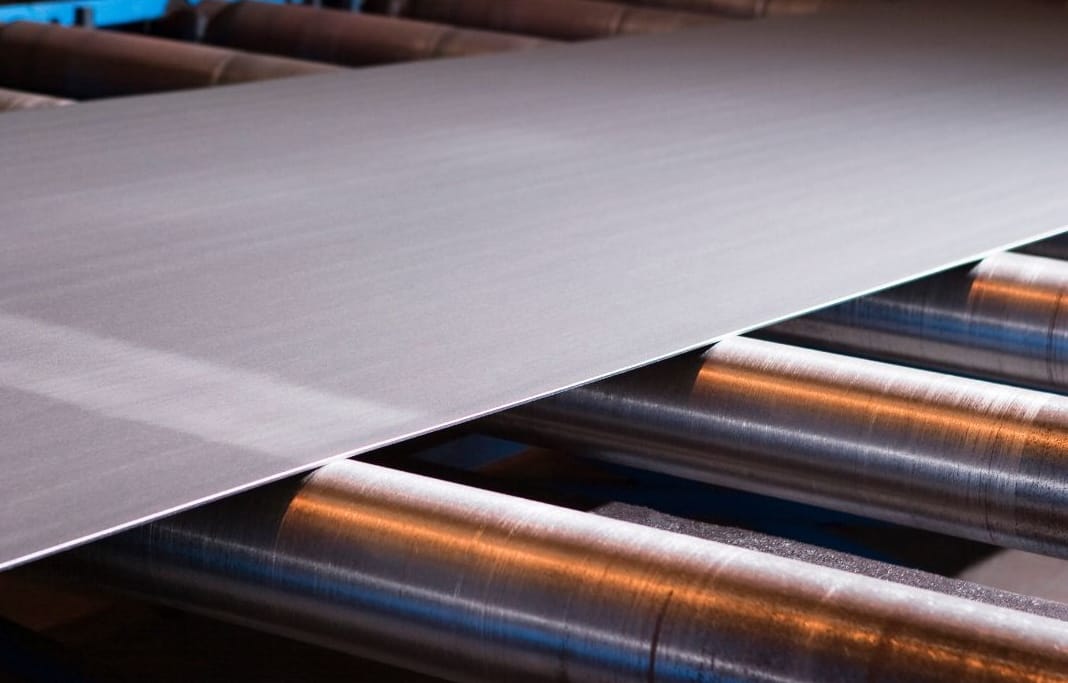

Sheet metal finishing improves durability, corrosion resistance, and appearance, helping metal parts last longer and perform well in their intended applications. The right finish can prevent rust, reduce wear, and give products a sleek, professional look.

Manufacturers and designers choose finishes based on factors such as material type, cost, and intended use. Some finishes focus on protection, while others are chosen for their appearance. This article covers six common sheet metal finishes—powder coating, bead blasting, e-coating, brushed finish, polished finish, and anodising—explaining their benefits, limitations, and typical applications.

Knowing these options helps businesses pick the best finish for their needs, whether for industrial machinery, consumer electronics, or architectural components.

A dry finishing process like powder coating is efficient for sheet metal finishing. The user sprays an electrostatically charged powder onto a piece of metal and then cures it under heat. This forms a thick, even layer that bonds to the surface, creating a strong and long-lasting finish.

It provides good resistance to scratches, chipping, and corrosion, making it a popular choice for both functional and decorative applications. Available in a wide range of colours and textures, it is often used on automotive parts, household appliances, and outdoor furniture.

In the automotive industry, powder coating is extensively used for its durability and aesthetic versatility, making it ideal for components like wheels and engine parts. Since it contains no solvents, it is also considered an environmentally friendly alternative to liquid coatings. However, powder coating has some limitations. It is not ideal for very thin coatings, as excessive thickness can affect precision components. It can also be difficult to repair, as touching up requires recoating the entire surface.

It can also be used to clean, smooth, and texture metal surfaces by propelling fine glass beads or other abrasives at high pressure. This process removes surface contaminants and imperfections, leaving a uniform, matte finish. For example, the medical sector uses bead blasting to achieve smooth, matte finishes on surgical instruments, reducing glare and improving sterilisation efficiency. It is commonly used in medical, aerospace, and decorative applications, where a clean and refined look is important.

Unlike some other finishing methods, bead blasting does not remove significant amounts of material, making it a gentle but effective way to increase the surface quality. The resulting texture reduces glare and improves the appearance of metal components. However, because it exposes fresh metal, the surface may be more prone to oxidation. In many cases, a protective coating or additional treatment is needed to maintain the finish over time.

Electrocoating (E-Coating for short) is a process where metal parts are submerged in a liquid paint bath and electrically charged, causing the coating to adhere evenly to the surface. The coated parts are then cured in an oven to create a smooth, durable finish. This method ensures full coverage, even on complex shapes and hard-to-reach areas, making it a popular choice for automotive parts, electrical enclosures, and industrial equipment. E-coating can be applied to vehicle bodies to provide uniform corrosion protection, enhancing the longevity of automotive components.

One of the main advantages of e-coating is its strong corrosion resistance. The uniform layer protects against moisture and environmental damage, helping metal components last longer. However, while e-coating provides a reliable protective base layer, it is often used as a primer rather than a final finish. For applications where aesthetics matter, an additional powder coating or topcoat is usually applied.

This type of finish is achieved by running an abrasive belt or brush over the metal surface to create a consistent, linear grain pattern. This process removes minor imperfections and gives the metal a sleek, textured appearance. It is widely used in kitchen appliances, architecture, and consumer electronics, where a modern and professional look is required.

One of the key benefits of a brushed finish is its ability to mask small scratches, making it a practical choice for high-touch surfaces. However, the texture also makes it prone to fingerprints and smudges, which may require regular cleaning. Over time, the finish can wear down, especially in areas exposed to frequent handling, but proper maintenance helps preserve its appearance.

A polished finish is created by mechanically buffing the metal surface until it becomes smooth and highly reflective. This process removes imperfections and increases the material’s natural shine, making it a popular choice for luxury goods, decorative metalwork, and automotive trim. The luxury watch industry employs polished finishes to improve the visual appeal and premium feel of timepieces. The mirror-like effect can improve a product’s overall appearance.

Beyond aesthetics, polishing also provides some protection against corrosion, as the smooth surface reduces areas where moisture and contaminants can accumulate. However, this type of finish shows scratches easily and may require frequent maintenance to keep its glossy look. In high-contact environments, regular cleaning and occasional re-polishing help maintain its quality over time.

Anodising is an electrochemical process that thickens the natural oxide layer on metal surfaces, improving corrosion resistance and wear durability. It is most commonly used on aluminium components to improve corrosion resistance and surface durability, which are critical for aerospace applications. This finish is widely used in aerospace, consumer electronics, and architectural applications, where both protection and appearance matter.

One of the key advantages of anodising is the ability to add colour to metal without using paints or coatings. The anodised layer integrates with the metal, creating a finish that is fade-resistant and long-lasting.

However, this process is limited to certain metals and can be costly for large parts. While anodising strengthens the surface, it does not make the metal scratch-proof, so additional treatments may be needed for high-wear applications.

Choosing the right sheet metal finish is essential for both durability and aesthetics. Each finish—whether powder coating, bead blasting, e-coating, brushed, polished, or anodised—offers distinct advantages in corrosion resistance, wear protection, and design appeal. The right selection ensures your metal components not only look great but also stand up to environmental and operational demands.

At Greengate Metal Components, we understand that every project has unique requirements. Whether you’re prioritising strength, longevity, or a specific aesthetic, our expert team can guide you in selecting the most suitable finish for your application. Get in touch with us today to discuss your project needs and explore the best finishing options for your sheet metal components

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...