How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

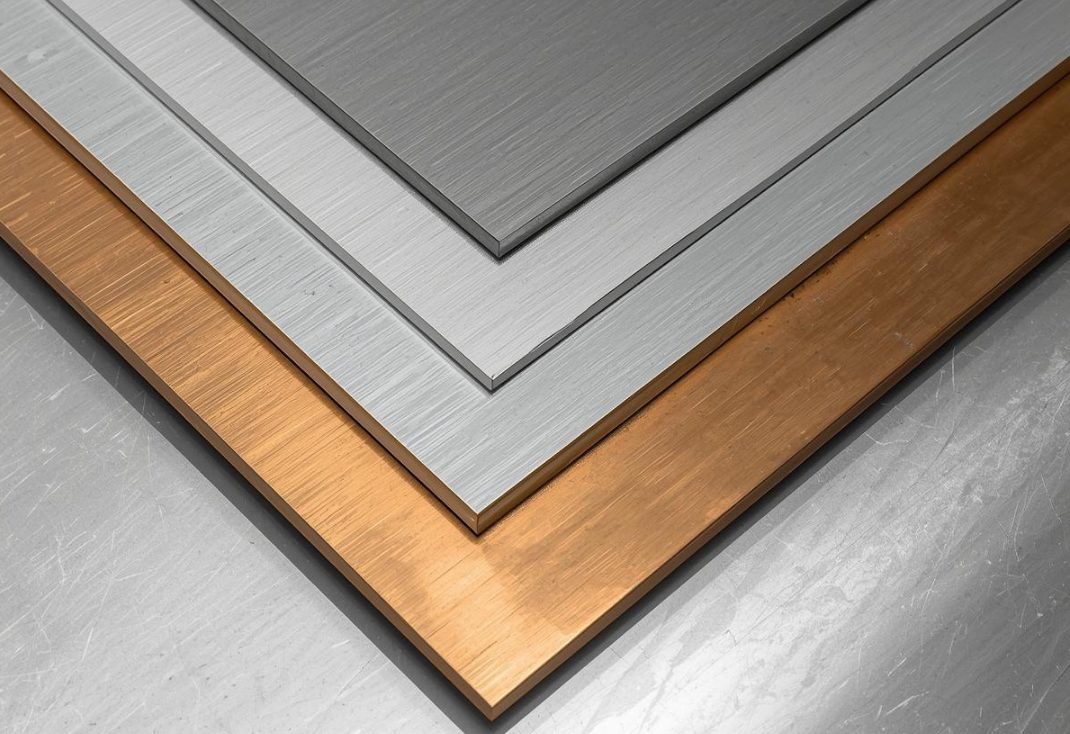

Choosing the right metal isn’t just about strength or price – it’s about understanding what each type brings to the table. Whether you’re designing a product, specifying parts for construction, or planning fabrication, your material decision can affect everything from cost to corrosion resistance.

At Greengate Metal Components, we regularly help clients weigh up different metals and their uses. Below is a simple breakdown of nine common metal types and where they typically work best – a solid starting point for early-stage planning.

Key Traits: Resists corrosion, easy to clean, strong under pressure

Common Uses:

Stainless steel is, in a way, the all-rounder of metals. It looks clean, performs well in harsh environments, and doesn’t rust easily. In areas where hygiene matters – think catering, healthcare, or clean manufacturing – it’s often the safest bet. Greengate’s stainless steel components are used across projects where durability and compliance go hand-in-hand.

Key Traits: Affordable, easy to work with, welds cleanly

Common Uses:

Mild steel might not sound exciting, but it’s one of the most widely used metals for a reason. It shapes well, doesn’t cost much, and suits a range of finishes. Greengate supplies a lot of this material for jobs where cost-effectiveness and speed are key – particularly in building frameworks and general-purpose brackets or panels.

Key Traits: Lightweight, naturally corrosion-resistant, conducts electricity

Common Uses:

Aluminium properties make it ideal where weight and strength need to be balanced. It’s lighter than steel but still surprisingly strong for its mass. It doesn’t rust in the usual way, either. This makes it a favourite in transportation and electronics. Our aluminium fabrication work often features in energy-efficient builds or precision components.

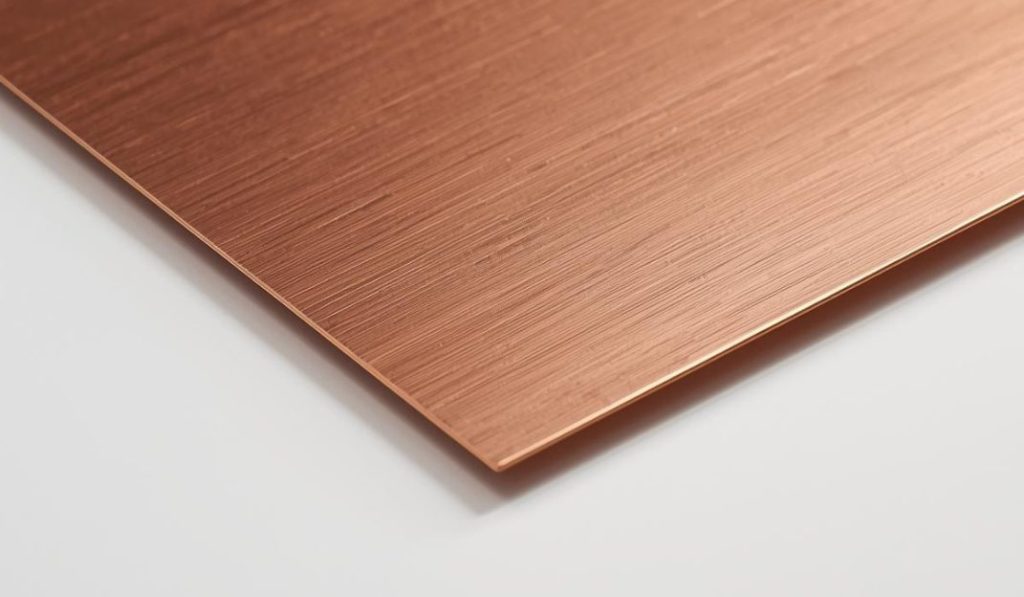

Key Traits: Excellent at conducting electricity, naturally antimicrobial

Common Uses:

Copper doesn’t just conduct – it does so better than almost any other metal. That’s why you see it in wires and circuit boards. It also stops bacteria from lingering on its surface, which is useful in healthcare and water systems. It’s a bit softer and more expensive than other options, but in the right place, it’s extremely effective.

Key Traits: Decorative, corrosion-resistant, easy to machine

Common Uses:

Brass is a blend of copper and zinc. It looks warm, machines easily, and handles weather reasonably well. From a design point of view, it’s often chosen more for appearance than performance. That said, it’s a great fit for fittings, signage, and interiors where both form and function matter.

Key Traits: Coated with zinc to protect against rust

Common Uses:

Galvanised steel starts life as regular steel, but it’s coated with a layer of zinc to stop it rusting. This gives it a longer life outdoors or in damp conditions. If you’re comparing galvanised vs carbon steel, the big difference is corrosion resistance – and it’s often a top choice for ductwork or site infrastructure.

Key Traits: Incredibly hard, keeps its shape under heat or pressure

Common Uses:

Tool steel is built to last. It can be hardened through heat treatment, meaning it won’t deform under stress. That makes it ideal for tools, dies, and forming equipment. If you’re looking at metal types for fabrication equipment or long-life tools, this one usually ends up on the list.

Key Traits: Tough and strong, used in structural applications

Common Uses:

Carbon steel is similar to mild steel but with higher carbon content. That makes it stronger, though slightly less ductile. It works well in large, load-bearing structures and is often used when safety and durability are at the forefront. At Greengate, we often work with clients comparing galvanised vs carbon steel for structural metalwork, depending on whether appearance or longevity matters most.

Key Traits: Resists corrosion naturally, often used as a protective layer

Common Uses:

Zinc might not always be used on its own, but it’s everywhere once you know what to look for. It’s often applied as a coating to protect other metals, and its low melting point makes it perfect for detailed die-casting. In short, it’s a quiet workhorse in many components, especially in electronics and mechanical parts.

Every metal on this list serves a purpose. Some offer strength, others give you corrosion resistance, conductivity, or aesthetic appeal. The trick is understanding what your build really needs – and choosing a metal that fits both your performance expectations and your budget.

If you’re still working through options, Greengate Metal Components can help. We’ve supported hundreds of teams with material selection, fabrication advice, and production-ready solutions. Get in touch if you’d like to talk through your project.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...