How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

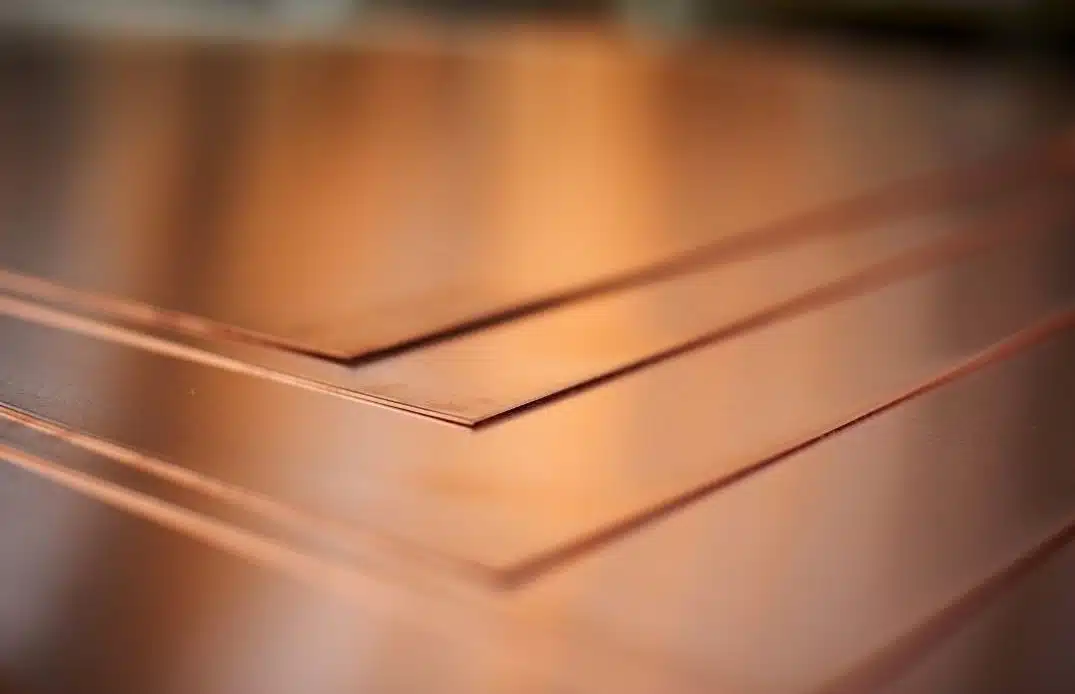

Copper has, in many ways, become one of the most adaptable materials in modern manufacturing.

Its strength, conductivity and corrosion resistance make it incredibly useful across an impressive range of settings. From precision electronics to building façades, copper fabrication plays a part in helping industries design reliable, high-performing and visually appealing components.

It’s not only the technical properties that make copper so appealing, though. It’s a material that shapes easily, lasts for decades and carries a distinctive aesthetic quality that no coating or substitute quite replicates. What’s interesting is that every sector values it differently. For some, it’s the electrical conductivity. For others, it’s the hygiene or the visual charm.

That’s why copper fabrication services support such a broad mix of sectors, each relying on its performance in a slightly different way.

In aerospace fabrication, precision is everything. Every material used must handle extreme temperature changes, vibration, and stress without losing performance. Copper fabrication proves especially valuable here, as copper alloys can deliver a mix of strength, conductivity, and thermal efficiency that few other materials can match.

Within avionics and electrical systems, copper components help maintain consistent energy flow and minimise heat build-up. These same properties make copper sheet metal fabrication a preferred choice for thermal management parts and connectors inside aircraft control systems. The ability to shape and form copper into complex geometries also supports lighter, more efficient designs that meet strict aerospace standards.

For manufacturers focused on high-performance capability, copper fabrication services often provide the accuracy and material reliability that flight-critical parts demand. In that sense, it’s more than a material; it’s part of what keeps modern aircraft operating safely and consistently.

Architecture often combines function and artistry, and copper fits beautifully into that balance. Its warm tones and natural ability to age gracefully make it a favourite for designers who want a surface that tells a story over time. With copper fabrication, cladding, and roofing can shift from bright metallic to rich green patina, adding character and distinction to any structure.

Architects and builders often specify copper sheet metal fabrication for façades, trims, and decorative panels because it resists corrosion and weathering, even in demanding climates. Beyond its appearance, copper is practical too, offering long-term performance with minimal maintenance. Whether for heritage restoration or bold contemporary design, custom copper fabrication supports projects that call for both structural reliability and visual identity.

In short, copper metal fabrication gives architectural projects a mix of resilience and timeless beauty that few other materials can quite replicate.

In healthcare environments, materials need to do more than look clean; they must actively support hygiene.

Copper fabrication stands out here because copper naturally limits the spread of bacteria, making it ideal for sterile areas such as laboratories, clinics and production facilities. Its antimicrobial surface continually works to reduce contamination risks without the need for constant chemical cleaning.

Hospitals and pharmaceutical companies often specify copper components for door handles, worktops, sinks and enclosures where hygiene cannot be compromised. In addition, copper’s conductivity and durability make it reliable for specialist medical devices and containment systems.

These qualities explain why copper fabrication UK suppliers are increasingly supporting medical projects, offering precision parts that blend cleanliness with structural integrity. For many healthcare designers, this combination of hygiene and engineering strength makes copper medical metal fabrication a practical and reassuring choice.

Public-facing machines such as kiosks, ticketing units, and vending systems need materials that handle constant use without losing their appearance or functionality. Copper fabrication is often chosen because copper resists corrosion and wears remarkably well, even in busy environments. Its durability helps keep machine casings and panels looking professional for longer, which is especially important where customers interact directly with the surface.

Another reason copper components perform so effectively in this sector is their compatibility with internal electronics. Copper’s conductivity and natural shielding help reduce interference and support reliable power flow within control systems. In that way, copper sheet metal fabrication doesn’t just improve external durability; it contributes to the overall performance of the equipment.

This mix of practicality and presentation makes copper metal fabrication a dependable option for manufacturers creating long-lasting, high-quality public-use machines.

Few industries test the toughness of materials quite like mining. Equipment used in extraction, crushing, and transport faces extreme heat, vibration, and abrasion. Copper fabrication provides a dependable answer here because copper alloys combine strength with excellent conductivity, allowing them to withstand demanding conditions while supporting electrical efficiency.

Heavy-duty copper components are used in power systems, grounding networks, and control assemblies across mines and processing plants. Their ability to maintain performance under stress reduces downtime and extends the life of expensive machinery. That kind of reliability translates into long-term cost efficiency, something every operator values.

For companies focused on sustainable growth and reduced maintenance, copper fabrication services offer a practical route to improved equipment longevity. In many ways, industrial copper applications like these prove how adaptable and resilient the material continues to be in modern heavy industry.

Technology-led industries depend heavily on secure, efficient enclosures to protect their systems. Copper fabrication offers a strong advantage here, particularly in projects where electronic integrity is essential. The material’s excellent conductivity gives it natural electromagnetic interference shielding, which helps safeguard sensitive equipment in telecoms, control panels and data centres.

At the same time, copper’s ability to disperse heat makes it a reliable option for power systems and server cabinets that operate continuously. Manufacturers often prefer copper sheet metal fabrication for these assemblies because it combines formability with mechanical strength, helping designs remain stable under load.

Through custom copper fabrication, businesses can specify the dimensions, finish and performance level they need. That flexibility means everything from high-tech communication enclosures to industrial cabinets benefits from both structural reliability and electrical protection.

Copper continues to prove its worth across a remarkable range of industries. Its mix of conductivity, durability, formability and visual appeal means that every sector, from aerospace and architecture to mining and manufacturing, benefits in a slightly different way. Whether it’s for hygiene, precision, or reliable performance, copper fabrication remains a trusted choice for businesses seeking dependable, high-quality results.

At Greengate Metal Components, our expertise in sheet metal fabrication supports companies across the UK that need custom copper fabrication and high-performing assemblies built to specification.

To explore how your next project could benefit from our experience and precision, contact us today.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...