How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

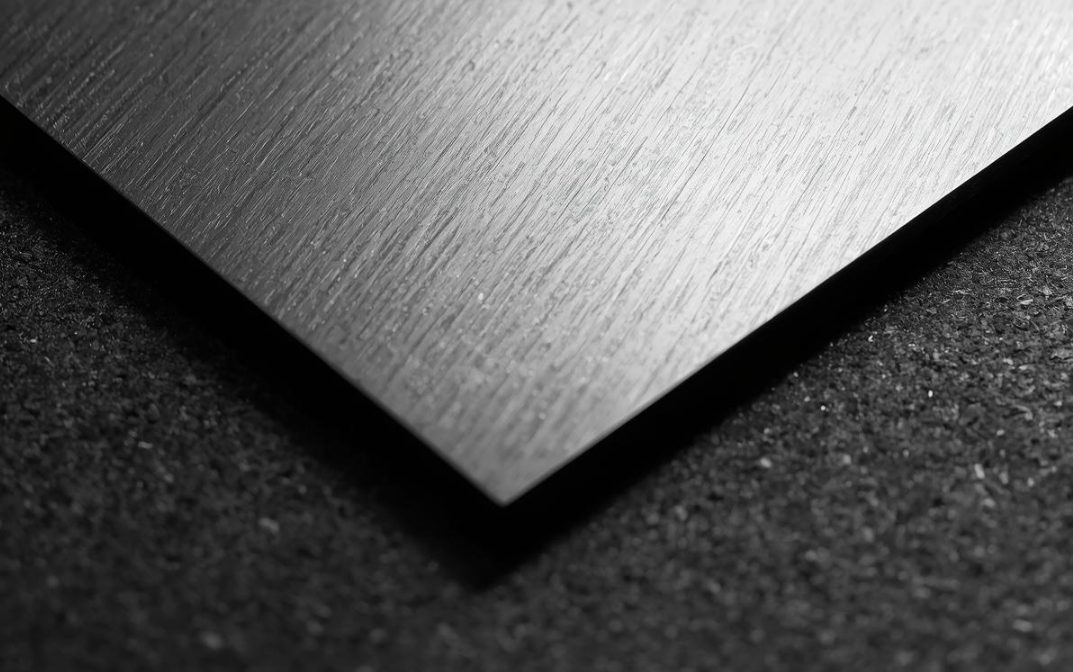

Stainless steel is used just about everywhere — and with good reason. Its balance of strength, corrosion resistance, clean finish, and long-term performance has made it one of the most relied-upon materials across industries. From food production and surgical tools to cladding and chemical tanks, it’s a material that works hard without complaint.

At Greengate Metal Components, we work with stainless steel every day. This guide outlines its key properties and alloy types, explains why it performs so well in varied conditions, and shares how we use it to meet our clients’ strict hygiene, strength, and tolerance needs.

The standout property of stainless steel is its corrosion resistance. It contains chromium — usually at least 10.5% — which reacts with oxygen to form a passive oxide layer on the surface. This layer self-heals when scratched or damaged, helping prevent rust and wear even in exposed or wet environments.

That’s why stainless steel is often chosen for marine components, exterior architectural panels, and anything food-grade. The material resists not just water, but acids, alkalis, and even salt spray to a point. This property alone is often enough for clients working in aggressive environments to make the decision easy.

Despite its clean appearance, stainless steel is incredibly strong. It holds up under load, resists impact, and copes well with vibration or repeated stress. Depending on the alloy and finish, it can offer both high tensile strength and excellent fatigue resistance.

This dual ability makes it just as suitable for visible applications — such as staircases or handrails — as it is for structural parts. At Greengate, we often use stainless steel where reliability is essential but weight or space is limited, particularly in custom parts for machinery and assemblies.

Not all metals perform well under heat, but stainless steel can handle elevated temperatures without losing its shape or compromising strength. Some grades, including 304 and 316, maintain their performance up to around 870°C in continuous service and even higher in short bursts.

This property is useful in food processing, commercial ovens, industrial heating systems, and exhaust components. Stainless steel does not warp easily, which is part of what makes it dependable in fire-resistant metal materials for demanding sectors.

One of the reasons stainless steel is trusted in medical, pharmaceutical, and food environments is its surface structure. It’s smooth, non-porous, and difficult for bacteria to cling to. Unlike some coated metals, stainless steel doesn’t chip or flake, and it can be sterilised repeatedly without degrading.

In practical terms, that makes it ideal for surgical trays, cleanroom fittings, and work surfaces in commercial kitchens. Greengate’s stainless steel components are often specified for environments where cleanliness, safety, and ease of maintenance can’t be compromised.

Although it’s tough, stainless steel can still be cut, formed, welded, and finished without excessive effort — especially when working with the right machines and techniques. It resists scratches and staining, which helps reduce upkeep long-term.

Compared to carbon steel or galvanised materials, it doesn’t need painting or special coatings to maintain performance. For sheet metal fabrication services where efficiency and reliability matter, stainless tends to deliver with fewer downstream costs.

Stainless steel is 100% recyclable. It doesn’t degrade when reprocessed, and many of the sheets in use today already contain a significant proportion of recycled content. As sustainability becomes a higher priority across supply chains, this property helps manufacturers and buyers meet environmental targets.

Using stainless steel also means fewer replacements, less maintenance, and reduced waste over time. From a greener supply chain perspective, it ticks a lot of boxes for sustainable metal fabrication.

Not all stainless steels behave the same. They fall into four main categories, each with its traits and typical use cases:

Choosing the right alloy depends on a mix of strength needs, corrosion exposure, temperature tolerance, and fabrication requirements. At Greengate, we help clients pick the most cost-effective and practical option for the job — especially in bespoke stainless steel fabrication.

For us, stainless steel isn’t just another material on the shelf — it’s part of how we consistently deliver clean, accurate, and long-lasting results. Whether we’re forming enclosures, cutting clean edges, or welding smooth seams, the properties of stainless steel support a high standard of finish.

Many of our customers work in hygiene-critical industries or demand tight tolerances and extended life from components. That’s where stainless proves its worth. The balance of cleanliness, toughness, and reliability makes it one of our most requested materials for precision builds.

Stainless steel continues to be a go-to material for good reason. It resists rust, keeps its strength in tough conditions, stays clean, and lasts for decades. With multiple alloy types to suit different applications, it offers real flexibility for anyone involved in design, manufacturing, or specification.

If you’re planning a project and want help selecting the right grade or fabrication method, Greengate Metal Components can assist. Our experience with stainless spans everything from high-volume parts to one-off precision work — and we’re happy to guide you through what’s possible.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...