How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

Selecting the right cutting method for sheet metal impacts precision, cost, and production efficiency. While some may compare laser cutting and water jet cutting, for sheet metal fabrication, fibre laser cutting stands out for its accuracy, speed, and overall reliability.

Greengate Metal Components uses fibre laser technology exclusively for these reasons. Here’s a breakdown of why fibre laser cutting is the most suitable method for sheet metal, and why water jet cutting is generally not recommended.

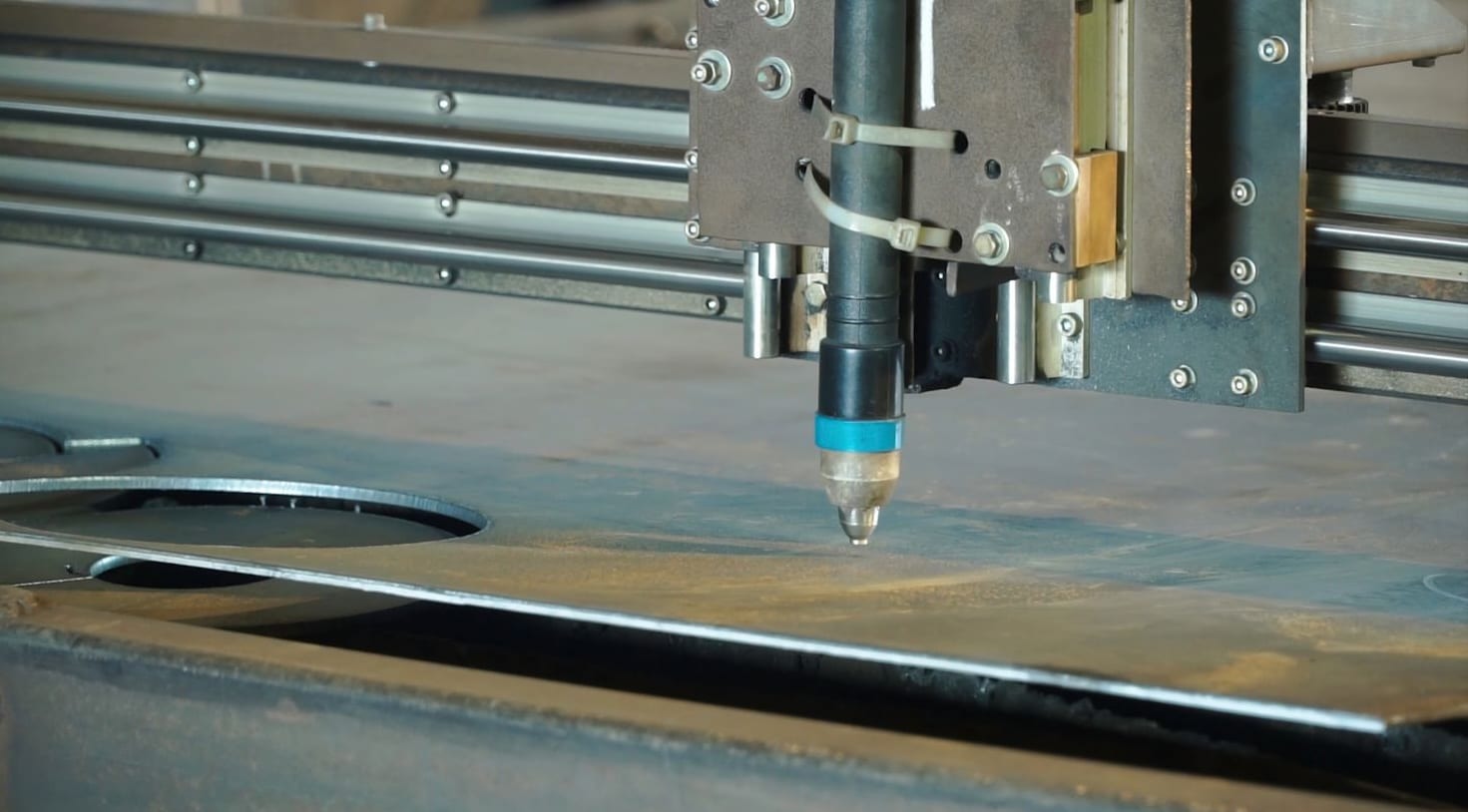

A laser cutter doesn’t just cut — it melts, vaporises, or blows away metal with an incredibly focused beam of light. Fibre laser cutting, specifically, is what Greengate uses, and that’s partly because it’s highly efficient on flat sheet metal. It’s also fast — extremely fast — especially when you’re dealing with thinner gauges.

So, how does it actually work? In short, fibre lasers channel amplified light through fibre optic cables to produce a pinpoint beam. That beam can slice through most metals with unbelievable precision. There’s hardly any waste, very little heat distortion, and hardly any finishing needed afterwards. It’s well-suited to everything from decorative panels to structural components.

In other words, it’s typically the go-to choice for modern metal fabrication techniques where repeatable accuracy really matters.

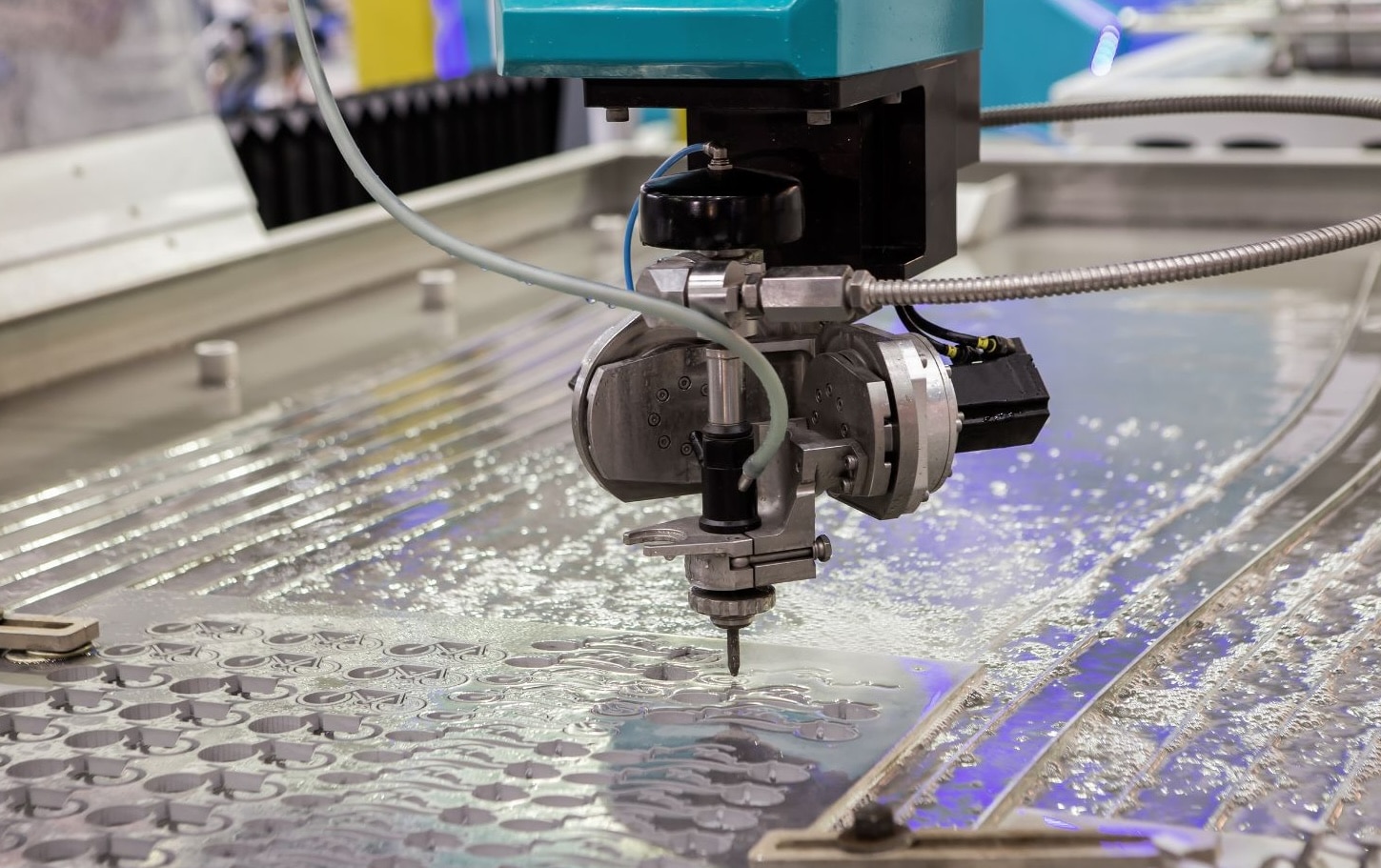

Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut materials. This technique is effective for very thick or composite materials, such as stone or rubber. However, it is not suitable for sheet metal fabrication. Water jets operate at slower speeds, create significant clean-up requirements, and generally require additional finishing steps.

For sheet metal, these drawbacks outweigh any advantages, making fibre laser cutting the preferred method.

When choosing between laser cutting vs waterjet, the finish quality and tolerances you can achieve are often where the difference becomes crystal clear. Here’s how they stack up:

For most precision metal cutting needs, fibre lasers give you neater results with less post-processing, which saves time and hassle down the line.

Laser cutters, particularly fibre lasers, are built for speed and finesse, especially with metals. Aluminium, stainless steel, mild steel, brass, copper — you name it, fibre lasers cut it cleanly, often up to around 25mm thick. That’s more than enough for most day-to-day metal fabrication techniques used by engineering firms and manufacturers.

Water jets, on the other hand, can cut through almost anything. From glass to granite to Kevlar, they don’t discriminate. However, this broader material compatibility does not translate well to sheet metal work. The process is inefficient, produces more waste, and lacks the precision and speed of fibre laser cutting.

So while water jet cutting has fewer material limits, fibre lasers tend to be the smarter, faster choice for clean, efficient cuts in metal.

When weighing up metal fabrication techniques, cost plays a big part. Let’s look at where laser cutting advantages stand out in numbers:

| Factor | Fibre Laser Cutting | Water Jet Cutting |

| Setup Cost | Medium | High |

| Running Cost | Low | High (abrasives, water) |

| Material Wastage | Very low | Moderate |

| Maintenance | Low | High |

| Operating Speed | Fast | Slower |

Water jets usually cost more to operate — they need constant streams of high-pressure water, garnet abrasive, and involve more wear on machinery. Laser cutters, especially fibre lasers, are leaner to run and quicker to get through jobs.

For production that’s regular or scaling up, fibre laser cutting tends to win on cost-efficiency. It’s quicker per cut and keeps your material use tighter, which in a way means more product for less scrap.

It’s not just performance that matters — how each method affects your workspace and footprint does too.

Fibre laser cutting is quieter, cleaner, and far more energy-efficient than you might expect. There’s no abrasive sludge, no water disposal issues, and no extreme noise levels. Operators tend to prefer working with laser machines because there’s less mess, less PPE, and lower risk.

Water jet cutting, by contrast, is louder, wetter, and heavier on clean-up. You’ve got high-pressure systems, potential splash hazards, and slurry waste to think about — which needs proper handling and disposal.

So, for firms keen to keep things neat, safe, and efficient, fibre lasers arguably bring fewer headaches, and that’s something most teams are more than happy to deal with.

So, laser cutter vs water jet — what’s the verdict?

For sheet metal applications, fibre laser cutting offers higher precision, faster cutting speeds, and lower operating costs compared to water jet cutting. Water jets are generally used for thick, non-metal materials and are not practical for sheet metal work.

Greengate Metal Components uses advanced fibre laser machines exclusively to produce accurate, clean parts with minimal waste and reliable turnaround times. To discuss your project or learn more, contact our team today.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...