How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

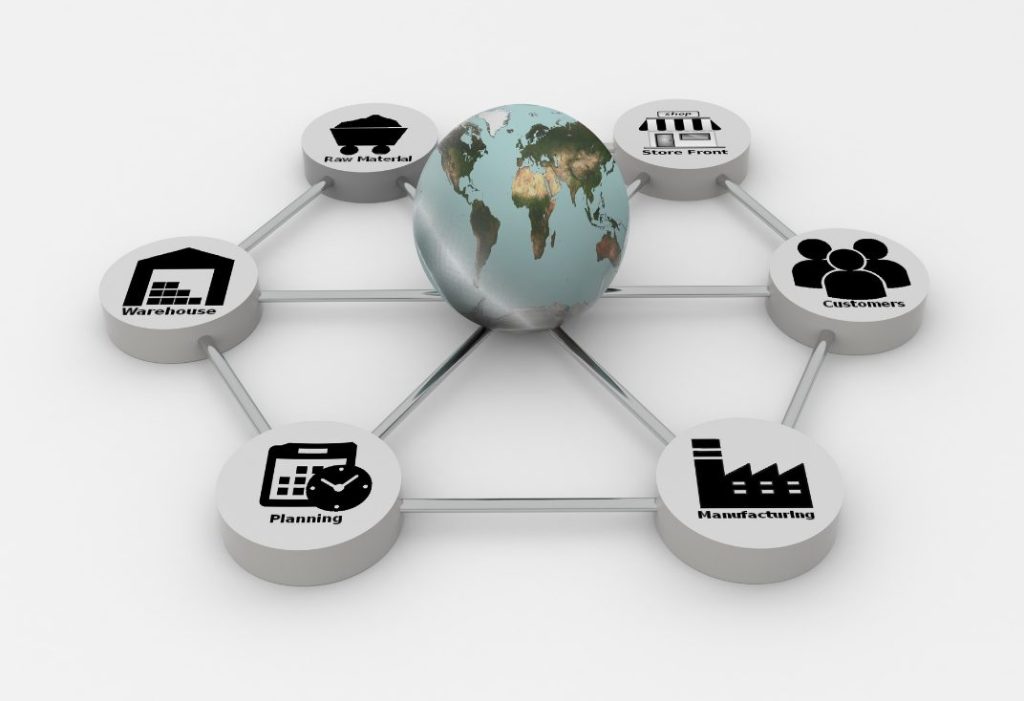

Keeping a metal production supply chain running smoothly is no small task. With rising raw material costs, tighter deadlines, and unexpected global disruptions, the pressure to deliver on time and without waste is higher than ever. For operations managers, procurement teams, and supply chain leaders, the focus is shifting – it’s no longer just about keeping up. It’s about getting ahead.

At Greengate Metal Components, we’ve seen first-hand how strategic adjustments to supply chain processes can significantly boost performance. This article lays out practical, forward-thinking ways to improve efficiency and reliability – with technology, relationships, and smart planning all playing a part.

Many delays start with miscommunication. Whether it’s an out-of-date drawing, an unclear delivery timeline, or a missed design change, the smallest oversight can snowball into a major disruption.

Improving clarity and speed in your communications is often the simplest way to reduce friction. Shared portals, real-time dashboards, or digital project tracking tools make it easier to align expectations across teams and suppliers. At Greengate, we actively encourage shared platforms and consistent contact to keep everyone in the loop, especially during fast-moving or multi-stage builds.

Stock-outs slow production. Overstock ties up cash. Neither is ideal. A smarter approach to stockholding starts with visibility – knowing exactly what you’ve got, where it is, and when it needs to be reordered.

Inventory management systems can track material usage in real-time, flag low stock levels, and even automate purchase orders based on demand trends. Even basic digital systems outperform spreadsheets when it comes to staying ahead. For more advanced teams, tying this into lean principles or vendor-managed inventory helps balance availability with minimal waste.

Not all suppliers are created equal. Inconsistencies in delivery, communication, or quality can disrupt entire workflows – which is why supplier relationships should be treated as a strategic asset.

At Greengate, we’ve always believed in building long-term partnerships, not just transactional handovers. Regular performance reviews, two-way feedback, and proactive scheduling discussions all help improve flow. Reliable suppliers offer more than just parts – they offer predictability, insight, and the ability to flex when circumstances change.

Accurate forecasting helps manufacturers plan better, buy smarter, and reduce excess waste. By analysing past orders, seasonal patterns, and market data, teams can develop more realistic production schedules and tighter procurement strategies.

Digital demand forecasting for fabrication doesn’t have to be complicated. Even small businesses can use simple dashboards to visualise what’s needed and when. For metal production supply chains, aligning orders with predicted demand can improve lead times and reduce the chance of bottlenecks.

Just-in-time metal production isn’t new – but with the right controls in place, it can be transformational. By aligning material flow with real-time production needs, businesses reduce inventory costs, limit storage requirements, and respond faster to changes in demand.

That said, it requires dependable suppliers, short lead times, and excellent internal coordination. Greengate often works with clients under JIT principles, particularly when producing in high volumes or managing space-restricted operations.

Automation in metal manufacturing is no longer optional for those aiming to scale efficiently. From CNC machinery to robotic cutting, bending, or welding, automating key processes helps improve repeatability, speed, and accuracy.

It doesn’t stop on the shop floor. Smart warehousing systems, RPA for purchasing, and digital twin models for layout planning are helping manufacturers spot inefficiencies and future-proof production lines. For Greengate, our own investment in automation ensures we can maintain high-precision production while keeping lead times tight.

There’s nothing more costly than a batch of components that fail inspection – especially after shipping or installation. A strong quality control system catches problems early and helps standardise checks across every order.

This could mean inline inspection equipment, barcode traceability, or a digital trail from raw material to final product. Involving suppliers in your quality system also helps close the loop and reduce rework. Greengate’s QC processes are built into every step of our metal fabrication services to make sure each part meets spec the first time.

Production doesn’t end at dispatch – and supply chain issues often crop up in the final mile. Improving routing, consolidating freight, or using local partners where possible can lower costs and reduce delays.

For sensitive metal parts, proper handling, labelling, and packaging are just as important. Damaged goods create rework, return costs, and downstream problems. Whether it’s coordinating with site schedules or optimising bulk shipments, logistics should be planned in parallel with production.

Supply chain improvements rarely happen overnight. But identifying weak links, setting measurable goals, and starting with small but meaningful changes can pay off faster than many expect.

At Greengate Metal Components, we understand what smooth, strategic metal production supply chains should look like. Whether you need just-in-time delivery, high-precision output, or dependable material availability, we can help make your supply chain stronger, faster, and more flexible.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...