How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it shapes a huge amount of everyday manufacturing.

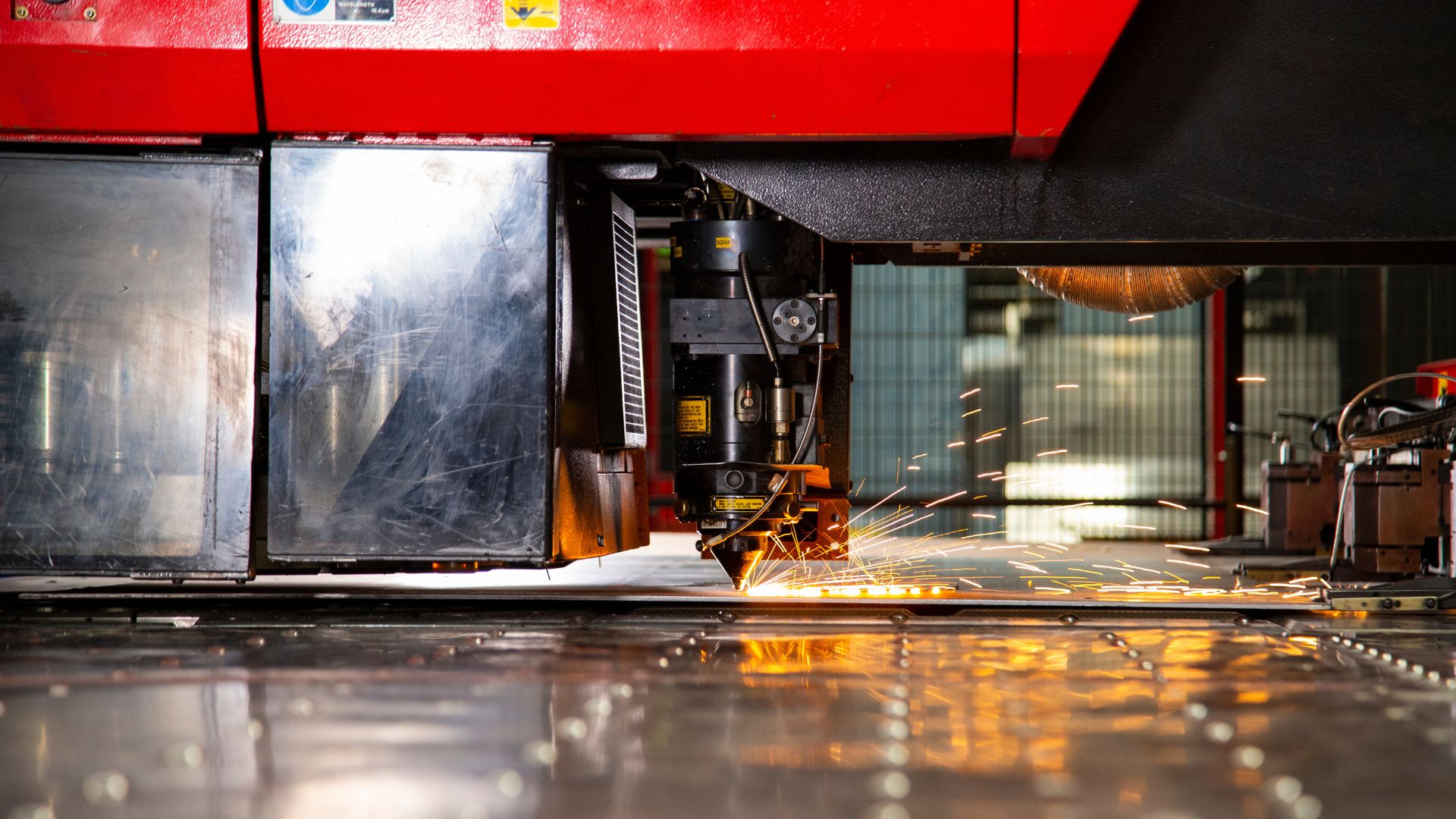

The process pairs computer control with concentrated light energy, which is focused tightly enough to cut metal with speed and consistency that traditional tools struggle to reach.

For engineers, manufacturing teams and buyers, knowing how a CNC laser cutting machine works gives clarity on what drives quality, repeatability and production efficiency.

This workflow starts with a digital design and finishes with parts ready for bending, welding or assembly, yet each stage plays a part in the final result.

In that sense, this article explains laser cutting in a practical way, so it stays useful without drifting into theory for its own sake.

At the heart of any CNC laser cutting machine sits the laser source, so this is where the cutting energy begins its journey.

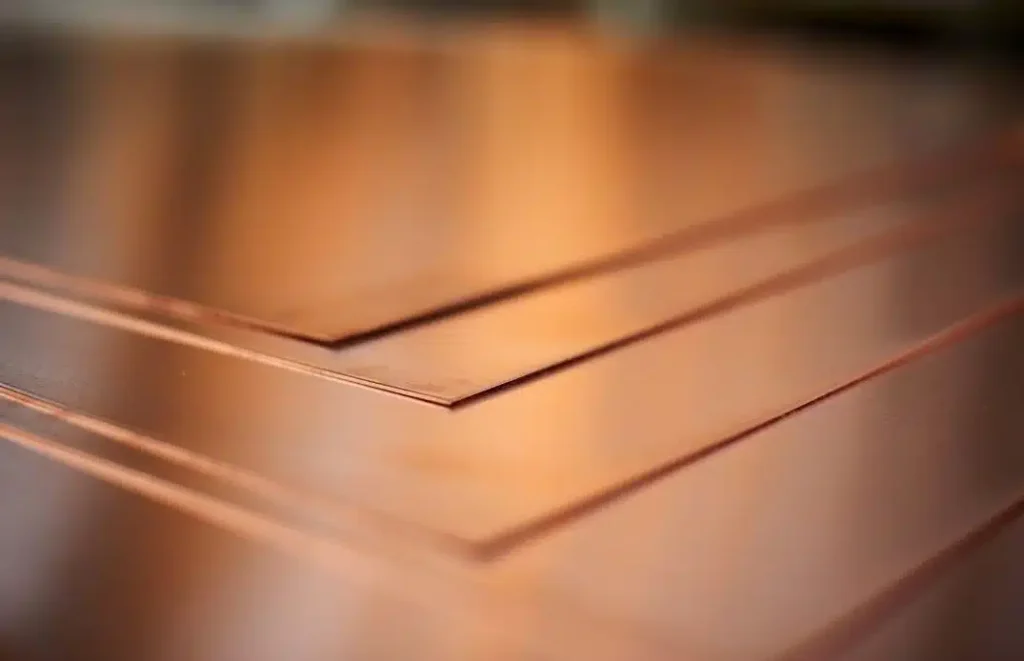

Modern systems usually rely on either a CO₂ laser or a fibre laser cutting machine, and the choice depends largely on material type and production needs. CO₂ lasers are often used on thicker materials, yet fibre systems tend to perform well on reflective metals such as aluminium and copper.

Inside the source, light energy is generated and amplified until it reaches the intensity needed for cutting, which is then directed with careful control.

The beam travels from the source to the cutting head through mirrors or fibre optic cables, and this path needs to stay clean and precisely aligned. Even a small deviation can affect cut accuracy, so this stage explains how raw energy becomes a dependable cutting tool within the CNC laser cutting process.

Once the laser is ready, the CNC laser cutting process shifts focus to movement and positioning, so accuracy can be maintained from start to finish.

Every job begins as a digital drawing created in computer aided design software, which defines the shape, dimensions and tolerances of the part. That drawing is then translated into machine instructions through computer aided manufacturing programming, which tells the system exactly how to move. Servo motors and stepper motors drive the cutting head or worktable with controlled precision, that is measured in fractions of a millimetre. This smooth, coordinated motion allows the machine to follow complex profiles without hesitation or drift.

In practice, this digital link between design and execution means CNC metal cutting delivers the same result again and again, even across long production runs.

For engineering teams, this reliability often shapes confidence in both the process and the supplier running it.

The cutting head is where control and energy meet, so it plays a central role in how the machine performs.

Inside the head, a lens focuses the laser beam into a very fine point that carries enough heat to melt or vaporise metal almost instantly. This focused point is what gives the CNC laser cutting process its clean edges and tight tolerances. The system continuously monitors the distance between the nozzle and the material through active height sensing, which helps keep the focal point stable. If that distance shifts, even slightly, edge quality and kerf width can suffer.

By making constant adjustments, the machine keeps each cut consistent across the sheet. In simple terms, the focal point decides the finish, and correct alignment reduces waste while improving part quality.

This explains why machines with well-maintained cutting heads tend to produce more reliable results.

As cutting begins, heat control becomes just as important as beam focus, so assist gases are introduced through the nozzle.

Common choices include oxygen, nitrogen or clean air, and each one affects the cut in a different way. Oxygen reacts with mild steel to increase cutting speed, yet nitrogen and clean air are often used on stainless steel and aluminium. These gases help clear molten material from the cut, protect the lens and influence edge appearance.

Pressure, flow rate and timing all matter, and small changes can alter both speed and surface finish. This balance of heat and airflow allows precision laser cutting to stay consistent across a range of materials. Rather than relying on light alone, the process uses controlled engineering to manage temperature and material behaviour at the cut edge.

Behind the visible movement of a CNC laser cutting machine sits a network of sensors and feedback systems, so accuracy can be maintained in real time.

These systems monitor position, alignment and focus as the machine runs, checking that each movement matches the programmed path. If variation is detected, adjustments are made instantly to keep the cut on track. Regular calibration routines help prevent gradual shifts that could affect accuracy over time. This level of monitoring supports consistent quality, even on complex geometries or extended production runs.

For manufacturers and engineers, this translates into confidence that every part meets the same standard. Traceability and repeatability are often the reasons CNC laser cutting is chosen for demanding applications.

After cutting is complete, attention turns to finishing and handling, so parts are ready for the next stage of fabrication.

Edges may show small burrs, slag or light oxidation, which are removed through brushing or light grinding. This step helps maintain surface quality, particularly where parts will be bent, welded or assembled later.

Finished components are then sorted and stacked, sometimes with automated handling systems. Careful handling reduces the risk of damage and keeps batches organised for downstream processes.

By combining controlled cutting with tidy finishing, a CNC laser cutting machine supports a smoother production flow. For many teams, this attention to detail separates a routine service from a fabrication partner they trust.

If you are reviewing laser cutting as part of a wider manufacturing plan, you can explore more of our laser cutting capability within this broader process, so you can see how these stages come together in practice.

For project-specific discussions or production support, contact us to talk through requirements and trust in the Greengate Metal Components’ team to deliver on your project.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

Copper has, in many ways, become one of the most adaptable materials in modern manufacturing. Its strength, conductivity and corrosion...