CNC Cutting vs 3D Printing: Which is Best for Precision Components?

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come back higher or lower than expected.

Every project brings its own mix of material, geometry and volume, which means prices shift depending on what is being cut and how it needs to be delivered. For engineers, buyers and procurement teams, having a clearer sense of what affects pricing helps with early budgeting and decision-making.

CNC cutting costs sit across machine time, material use, setup and finishing, so comparing jobs on headline price alone rarely tells the full story. This CNC cutting price guide breaks down the main influences on cost, so estimates feel grounded rather than guesswork.

CNC metal cutting costs come from several overlapping elements, so no two quotes ever look quite the same.

Material choice, part geometry, machine time and finishing requirements all affect how long a job runs and how efficiently it can be produced. Labour input, tooling wear and sheet nesting efficiency can push costs slightly up or down, even on similar parts. Batch size plays a role as well, since setup effort is shared very differently between one prototype and a full production run.

These CNC machining cost factors explain why there is no universal price list that fits every job. Each quote reflects a balance between accuracy, volume and time, that aims to deliver value without compromising quality.

Material selection has a strong influence on the cost of CNC metal cutting, so it is often one of the first things reviewed during quoting.

Some metals cut quickly and cleanly, yet others need slower speeds or higher gas use to maintain edge quality.

Aluminium, for example, is generally faster to process and causes less wear, which helps keep machine time predictable. Stainless steel takes longer to cut and increases wear on equipment, so the metal cutting service cost tends to rise.

Thickness adds another layer, since heavier sections need more energy and slower passes. In some cases, changing the material grade or thickness can almost double the cutting time for the same profile. That is why early material decisions affect the budget just as much as performance.

Batch size directly shapes the overall cost of CNC metal cutting, so it is one of the most common pricing questions.

Every job involves setup time for programming, calibration and test cutting, and that effort carries a fixed cost. When only one or two parts are required, that setup is absorbed by very few components, which raises the unit price. As quantities increase, the same setup cost spreads across more parts, bringing the average price down.

This explains how much does CNC cutting cost varies so widely between prototypes and production runs. Planning realistic batch sizes helps control spend while keeping accuracy and consistency where they need to be.

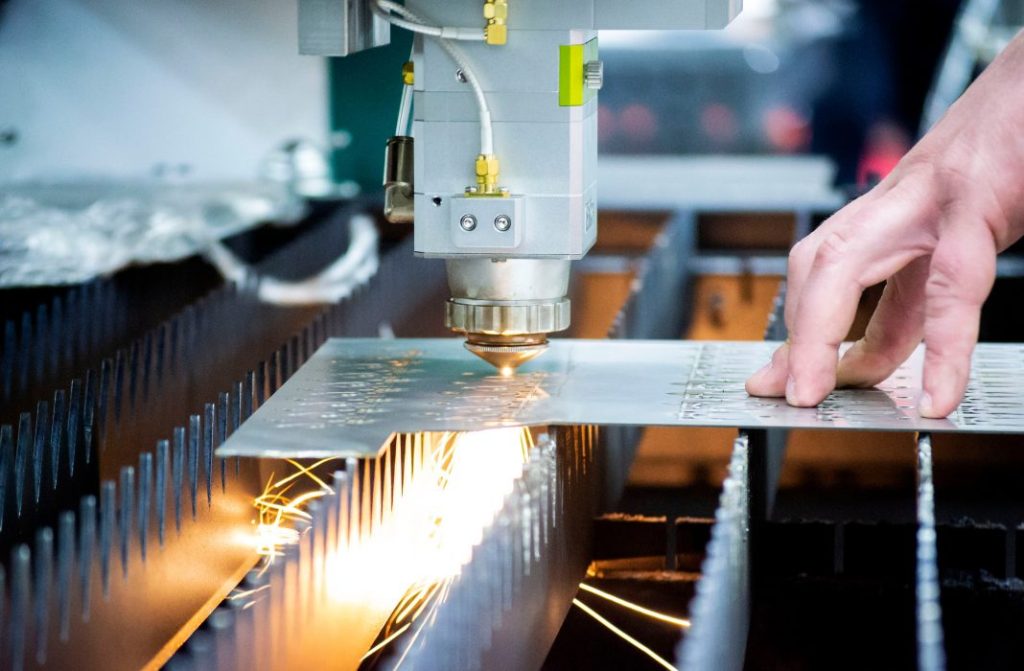

Not all CNC machines are suited to the same work, so capability affects pricing as well.

Two-axis and three-axis systems handle straightforward profiles efficiently, keeping running costs controlled. Five axis machines allow more complex geometries and tighter tolerances, yet they operate with higher overheads.

Fibre laser systems add another layer, delivering faster cutting speeds and finer detail than older technologies. These improvements can justify higher hourly rates when precision or finish is the priority.

Understanding CNC cutting services pricing means recognising how machine choice affects speed, flexibility and cost. For applications where accuracy matters most, Greengate Metal Components’ metal laser cutting capability offers a stable balance between performance and value.

Cutting is only part of the overall workflow, so finishing steps often influence the final cost more than expected.

Processes such as deburring, tapping, bending, powder coating, painting or welding all add time and material use. These stages might seem minor, yet they affect how parts fit, function and look once installed. A simple cut component becomes production-ready only after edges are cleaned, holes prepared, and surfaces are protected.

Multi stage projects need a clear definition early on; otherwise, additional work can push costs beyond initial expectations. Listing all finishing and assembly needs at the start allows pricing to reflect the full manufacturing process.

Timing influences pricing just as much as material or volume, so lead time should never be an afterthought.

Urgent work often attracts higher rates, since schedules need adjusting and resources may be reallocated. Overtime, expedited setup and tighter planning all contribute to increased cost. Longer lead times allow production to run more smoothly, which helps keep pricing stable.

A realistic CNC cutting price guide always considers time, because prototypes, short runs and large orders follow different planning paths. Allowing sensible time frames usually results in better value and fewer surprises between quote and delivery.

When viewed as a whole, the cost of CNC metal cutting reflects far more than the minutes a machine spends cutting material.

Design clarity, material behaviour, batch planning and finishing choices all shape the final figure. The most accurate estimates come from sharing complete drawings, quantities and expectations, so pricing mirrors the real scope of work. That approach supports better budgeting and fewer adjustments later on.

If you are comparing options or refining a project plan, you can contact us at Greengate Metal Components to discuss requirements and receive guidance that reflects real production rather than just assumptions.

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...

Copper has, in many ways, become one of the most adaptable materials in modern manufacturing. Its strength, conductivity and corrosion...