How Much Does a CNC Metal Cutting Service Cost?

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

The discussion around 3D printing vs CNC keeps coming up, so it reflects how manufacturing teams now weigh accuracy against flexibility in a very practical way.

Both processes shape materials differently; that is CNC cutting removes material through controlled motion and tooling, and 3D printing builds parts layer by layer from digital data. Each method suits a different set of priorities, yet both now sit side by side in modern production planning.

For engineers, designers and procurement teams, choosing between them often affects cost, lead time and long-term performance.

In sectors where precision CNC cutting already supports demanding applications, this comparison helps clarify where additive methods fit, and where traditional approaches still lead.

When tolerances matter, the difference between CNC cutting and 3D printing becomes fairly clear, so accuracy often drives the decision.

CNC cutting produces consistent results through tightly controlled tool paths, that means every movement follows the same programmed instructions each time. This repeatability supports tight tolerances across large batches, which explains why CNC for precision parts remains widely trusted in industrial settings. Subtractive machining allows sharp edges, defined features and predictable geometry, almost regardless of part volume.

3D printing, on the other hand, introduces variation through layer resolution and build orientation, so dimensional changes can appear between prints. Warping and shrinkage sometimes affect accuracy on complex or load-bearing parts, even with careful setup.

Additive systems continue to improve, yet CNC cutting still sets the reference point for repeatable precision in metal components.

Material choice plays a big role in the comparison, so looking at finish and strength helps separate the two processes.

CNC cutting works across metals, plastics and composites, producing parts with consistent structure and mechanical properties. Precision CNC cutting removes material cleanly, leaving surfaces with a smooth machined finish that often needs little extra work.

3D printed components rely on polymers, resins or metal powders, which open up design freedom yet behave differently under load. Layered construction creates visible lines on many printed parts, so surface treatment often follows printing. Sanding, coating or heat treatment may be needed to reach the required finish or strength.

In practical terms, CNC machining vs additive manufacturing comes down to whether surface quality or geometric freedom carries more weight in the application.

Speed often shapes early decisions, so comparing CNC cutting and 3D printing highlights how timing affects workflow.

3D printing suits rapid prototyping, that is, new ideas can move from screen to physical form without tooling or fixturing. Design teams use this speed to review fit, form and concept details during early development.

CNC cutting takes longer at the setup stage, yet once programming is complete, output becomes steady and predictable. For repeat orders or production runs, CNC machines deliver parts quickly with consistent quality.

Additive vs subtractive manufacturing each follows its own rhythm, so the better choice depends on whether immediate feedback or production throughput matters most.

Cost comparisons often focus on volume, so scale shifts the balance between CNC and 3D printing.

CNC cutting becomes more economical as quantities rise, that happens through repeatability, efficient cycle times and reduced waste. Precision CNC cutting supports consistent output, which limits rework and helps control unit cost.

3D printing suits low volume or one off parts, where tooling and programming would otherwise add expense. Material costs for printing, especially metal powders, tend to remain high, and finishing steps can add time.

Over longer production runs, CNC cutting usually delivers a lower cost per part. For early development or highly customised designs, 3D printing still offers financial flexibility before production decisions are locked in.

Customisation highlights one of the clearest differences, so engineers often raise it when comparing the two methods.

3D printing enables complex internal structures and lightweight forms that machining cannot easily produce. This freedom supports rapid iteration, which allows designs to evolve without reworking tools or fixtures.

CNC cutting offers a different benefit, producing functional prototypes from final-use materials. These parts behave like production components, giving designers reliable performance data early on.

Many teams now combine both approaches, using additive methods for development and CNC for precision parts. That blend supports creativity without sacrificing accuracy or reliability.

Reliability often shapes long-term decisions, so tooling and infrastructure matter as much as capability.

CNC cutting sits within a mature manufacturing framework, supported by inspection routines, traceability systems and quality control processes. This maturity gives confidence that parts will meet specification across repeated production cycles.

3D printing continues to develop, yet standardisation varies between machines, materials and suppliers. Consistency can become harder to maintain when scaling beyond prototypes.

For industries that rely on dependable output, precision CNC cutting remains the benchmark. Additive technologies still complement CNC workflows, particularly where design freedom adds value.

For teams weighing CNC cutting against additive options, this comparison helps frame the decision around accuracy, scale and material performance rather than trend alone.

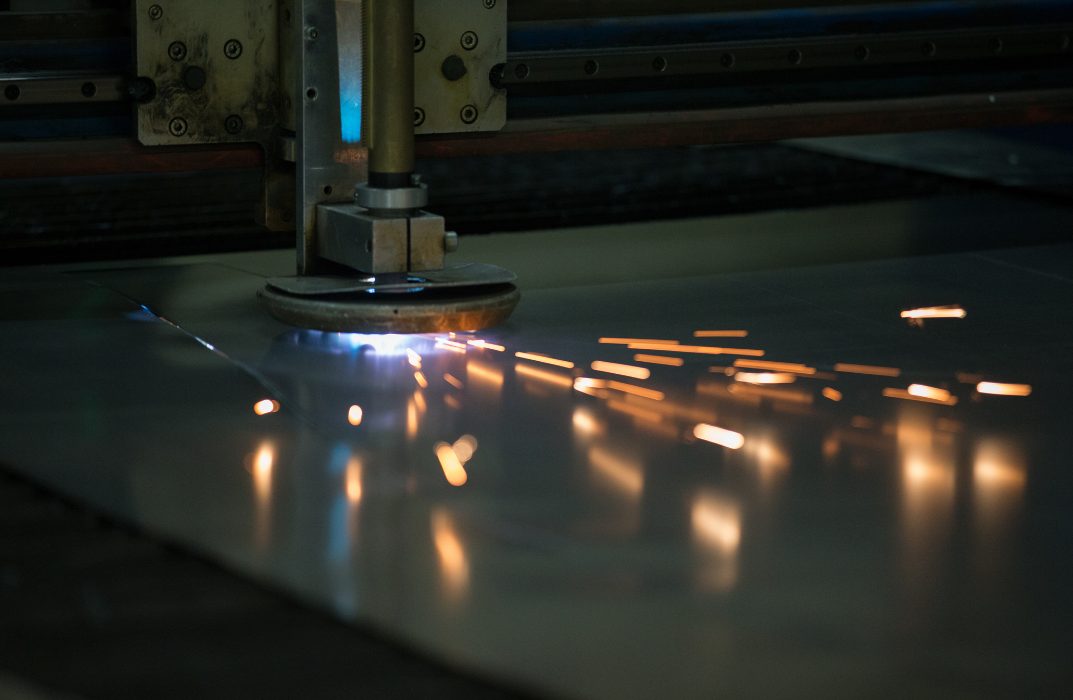

If you are assessing options for precision components, our approach at Greengate Metal Components to metal laser cutting reflects the strengths of our established CNC processes within real manufacturing environments. For projects that need clearer direction, you can contact us to discuss requirements with a team that works through these decisions every day.

The cost of CNC metal cutting is rarely a fixed number, so it often catches people out when quotes come...

CNC laser cutting sits quietly at the centre of modern metal fabrication, so it often goes unnoticed even though it...

Copper has, in many ways, become one of the most adaptable materials in modern manufacturing. Its strength, conductivity and corrosion...