Laser Cutting

Our Laser Cutting capabilities

Materials we laser cut

- Mild Steel

- Stainless Steel

- Aluminium

- Zintec / Galvanised Steel

- Copper

- Brass

- Coated Sheets

Metal thickness

- Mild Steel: 0.5mm-25mm

- Stainless Steel: 0.5mm-20mm

- Aluminium: 0.5mm-16mm

- Brass: 0.5mm-10mm

- Copper: 0.5mm-8mm

Sheet sizes

- Up to 3000 x 1500mm

Our laser cutting machinery

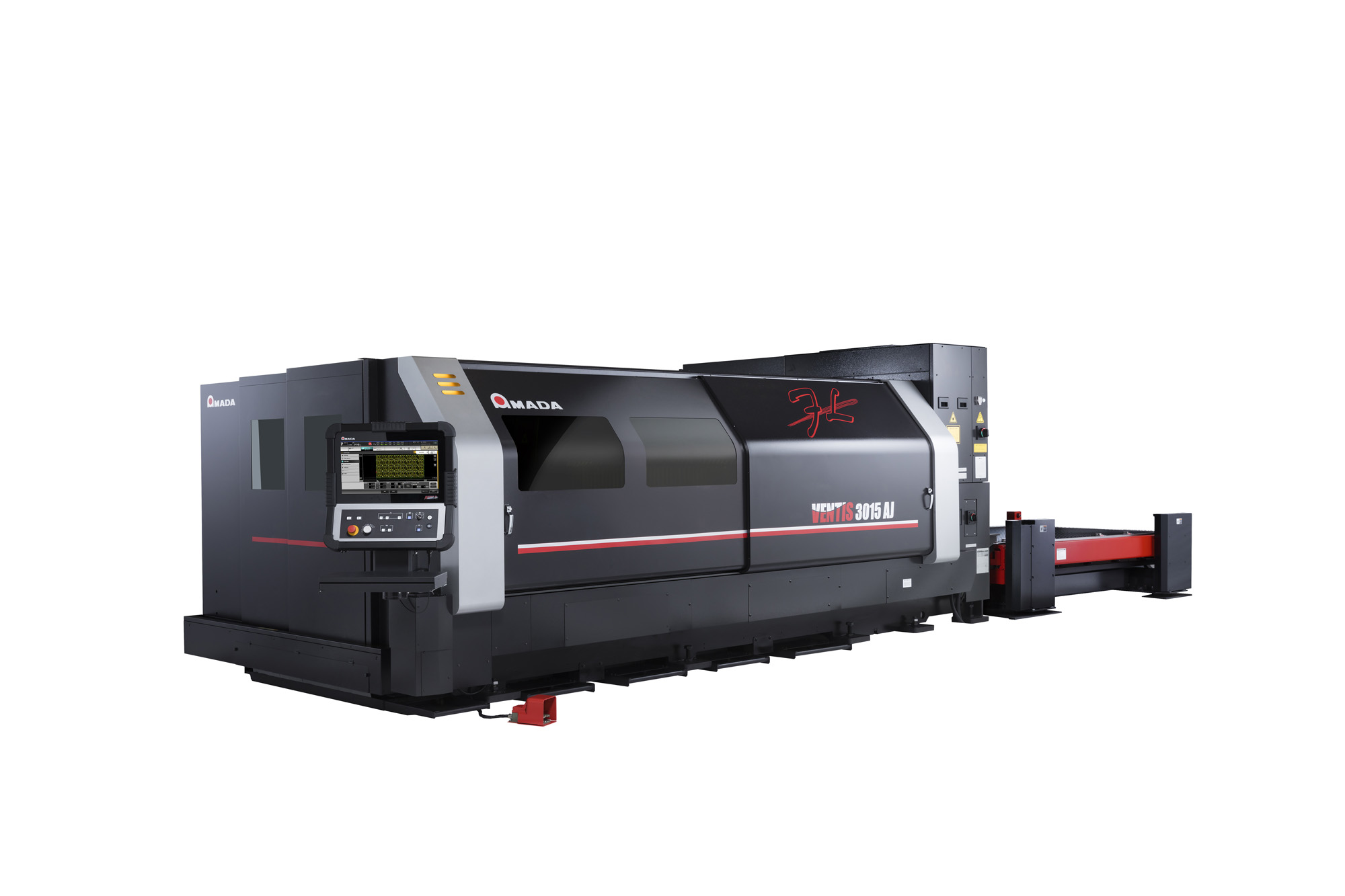

Ventis-AJ Fibre Laser

The VENTIS-AJ is the biggest innovation in sheet metal cutting and introduces the next generation of fibre laser processing machines.

What makes this technology truly revolutionary is the innovative beam shaping system that allows for precise control of the laser beam motion. Utilizing AMADA’s high power, single diode module fibre laser engines, the VENTIS is available as 4 kW or 6 kW. These engines provide a very high quality laser beam, allowing the 4 kW VENTIS-AJ to perform similar to 6-8 kW machines, and the 6 kW VENTIS-AJ to perform similar to 8-10kW machines, with much less power requirements and an unrivalled cutting quality.

What makes this technology truly revolutionary is the innovative beam shaping system that allows for precise control of the laser beam motion. Utilizing AMADA’s high power, single diode module fibre laser engines, the VENTIS is available as 4 kW or 6 kW. These engines provide a very high quality laser beam, allowing the 4 kW VENTIS-AJ to perform similar to 6-8 kW machines, and the 6 kW VENTIS-AJ to perform similar to 8-10kW machines, with much less power requirements and an unrivalled cutting quality.

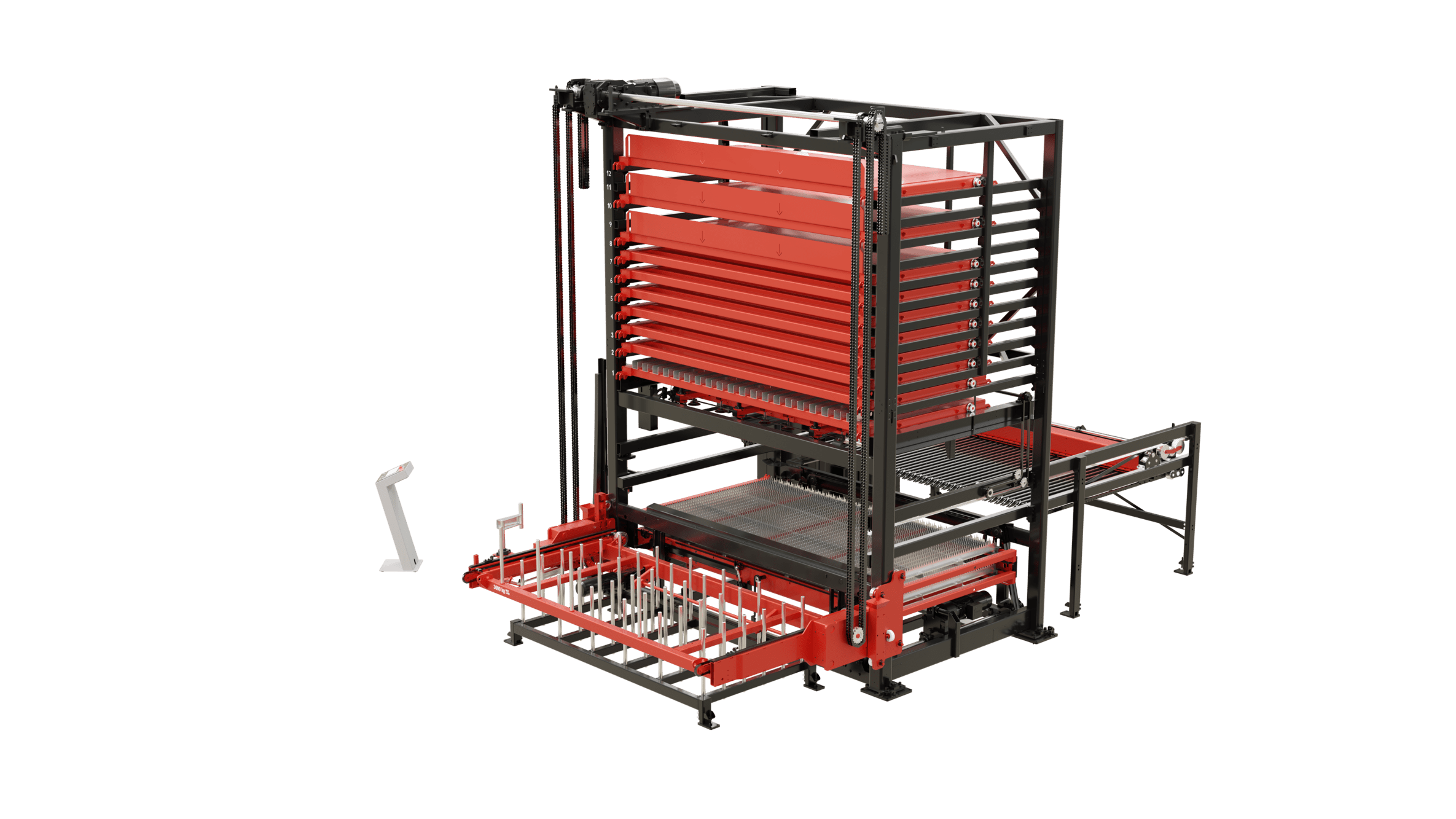

ASF II Loading Tower

ASF II is the new generation of automatic tower solutions for FO-lasers (flying optics lasers). The solution includes automatic loading and unloading of sheets to and from AMADA FO-lasers as well as storage of both raw material and worked sheets. It also optimizes the FO-laser utilization. Suction cups allow handling of different material types such as steel, aluminium and stainless steel. The tower storage system has a modular configuration, giving the user the ability to customize the number of pallets for raw material and for stacking.